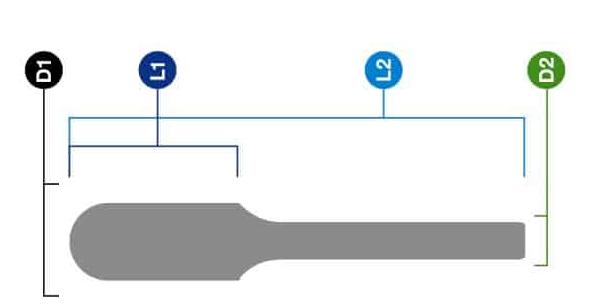

»Tipe C Silinder Ball Nose Tungsten Carbide Rotary Burr

Tipe C Silinder Bola Hidung Tungsten Carbide Rotary Burr

● Potongan: Tunggal, Ganda, Intan, Potongan Alu

● Coating: Could Coating by TiAlN

Metrik

| Model | D1 | L1 | L2 | D2 | Tunggal Cut | Cut pindho | Diamond Cut | Alu Cut |

| C0210 | 2 | 10 | 40 | 3 | 660-2924 | 660-2932 | 660-2940 | 660-2948 |

| C0313 | 3 | 13 | 40 | 3 | 660-2925 | 660-2933 | 660-2941 | 660-2949 |

| C0613 | 6 | 13 | 43 | 3 | 660-2926 | 660-2934 | 660-2942 | 660-2950 |

| C0616 | 6 | 16 | 50 | 6 | 660-2927 | 660-2935 | 660-2943 | 660-2951 |

| C0820 | 8 | 20 | 60 | 6 | 660-2928 | 660-2936 | 660-2944 | 660-2952 |

| C1020 | 10 | 20 | 60 | 6 | 660-2929 | 660-2937 | 660-2945 | 660-2953 |

| C1225 | 12 | 25 | 65 | 6 | 660-2930 | 660-2938 | 660-2946 | 660-2954 |

| C1625 | 16 | 25 | 65 | 6 | 660-2931 | 660-2939 | 660-2947 | 660-2955 |

inch

| Model | D1 | L1 | D2 | Tunggal Cut | Cut pindho | Diamond Cut | Alu Cut |

| SC-11 | 1/8" | 1/2" | 1/4" | 660-3278 | 660-3291 | 660-3304 | 660-3317 |

| SC-42 | 1/8" | 9/16" | 1/8" | 660-3279 | 660-3292 | 660-3305 | 660-3318 |

| SC-41 | 3/32" | 7/16" | 1/8" | 660-3280 | 660-3293 | 660-3306 | 660-3319 |

| SC-13 | 5/32" | 5/8" | 1/4" | 660-3281 | 660-3294 | 660-3307 | 660-3320 |

| SC-14 | 3/16" | 5/8" | 1/4" | 660-3282 | 660-3295 | 660-3308 | 660-3321 |

| SC-1 | 1/4" | 5/8" | 1/4" | 660-3283 | 660-3296 | 660-3309 | 660-3322 |

| SC-2 | 5/16" | 3/4" | 1/4" | 660-3284 | 660-3297 | 660-3310 | 660-3323 |

| SC-3 | 3/8" | 3/4" | 1/4" | 660-3285 | 660-3298 | 660-3311 | 660-3324 |

| SC-4 | 7/16" | 1" | 1/4" | 660-3286 | 660-3299 | 660-3312 | 660-3325 |

| SC-5 | 1/2" | 1" | 1/4" | 660-3287 | 660-3300 | 660-3313 | 660-3326 |

| SC-6 | 5/8" | 1" | 1/4" | 660-3288 | 660-3301 | 660-3314 | 660-3327 |

| SC-7 | 3/4" | 1" | 1/4" | 660-3289 | 660-3302 | 660-3315 | 660-3328 |

| SC-9 | 1" | 1" | 1/4" | 660-3290 | 660-3303 | 660-3316 | 660-3329 |

Deburring lan Welding Precision

Tungsten Carbide Rotary Burrs minangka alat sing penting ing bidang pengerjaan logam, sing misuwur amarga fleksibilitas lan kinerja dhuwur ing macem-macem tugas. Aplikasi utama alat kasebut kalebu.

Perawatan Deburring lan Welding.

Ing fabrikasi logam, penghapusan cermat saka burr sing dibentuk nalika ngelas utawa nglereni penting. Ketahanan nyandhang lan kekerasan saka Tungsten Carbide Rotary Burrs ndadekake banget efektif kanggo aktivitas deburring sing rinci.

Shaping lan Engraving Mastery

Digunakake kanggo mbentuk, ngukir, lan motong bagean logam sing rumit, burr rotary iki nuduhake keahlian kanggo nggarap macem-macem logam, kalebu paduan keras lan paduan aluminium.

Grinding lan Polishing Excellence

Penting ing pengerjaan logam kanthi presisi, utamane kanggo tugas nggiling lan polishing, Tungsten Carbide Rotary Burrs unggul amarga kekerasan lan daya tahan sing luar biasa, nyumbang banget kanggo khasiat ing proses kasebut.

Akurasi Reaming lan Edging

Asring pilihan sing disenengi kanggo ngowahi utawa nyaring ukuran lan wujud bolongan sing ana sajrone proses pabrikasi mekanik.

dandan lumahing Casting

Ing lapangan casting, Tungsten Carbide Rotary Burrs muter peran wigati ing njabut keluwihan materi saka casting lan Ngapikake kualitas lumahing sing.

Amarga efisiensi lan keluwesan sing dhuwur, Tungsten Carbide Rotary Burrs bisa digunakake ing macem-macem industri, kalebu manufaktur, ndandani otomotif, kerajinan logam, lan aerospace.

Keuntungan Wayleading

• Layanan sing efisien lan dipercaya;

• Kualitas apik;

• Rega Kompetitif;

• OEM, ODM, OBM;

• Macem-macem ekstensif

• Pangiriman Cepet & Bisa Dipercaya

Isi Paket

1 x Tipe C Silinder Bola Hidung Silinder Tungsten Carbide Rotary Burr

1 x Kasus Pelindung

● Apa sampeyan mbutuhake OEM, OBM, ODM utawa kemasan netral kanggo produk sampeyan?

● Jeneng perusahaan lan informasi kontak kanggo umpan balik sing cepet lan akurat.

Tambahan, kita ngajak sampeyan njaluk conto kanggo testing kualitas.