Mabasa

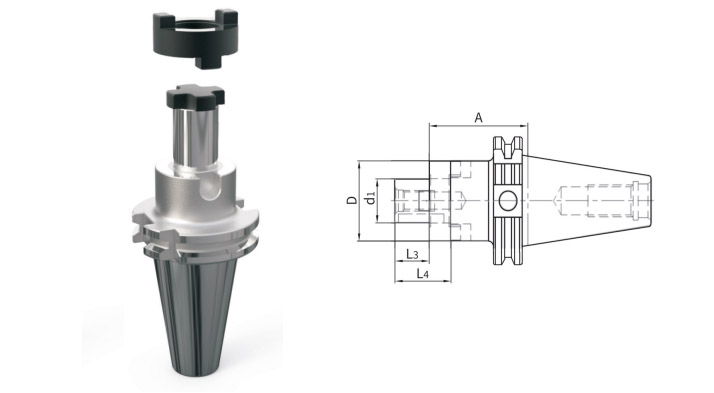

Yakagadzikana Clamping yeZvishandiso:

Iyo JT modhi yakasanganiswa yakatarisana nechigayo adapta chibatiso, ine yakasarudzika girove dhizaini, inogona kusungirira zvakasimba kucheka zvigayo zvine kureba kana kuchinjika grooves. Izvi zvinovimbisa kuti chishandiso chinoramba chakagadzikana panguva yekucheka-kumhanya-mhanya, kudzivirira chishandiso kusunungura kana kutamiswa, nekudaro kuvandudza machining kurongeka uye mhando yepamusoro.

Kuwedzera Kubudirira Kwekugadzirisa:

Ichi chibatiso chekushandisa chinotsigira kukurumidza kushanduka kwechishandiso, kuderedza chishandiso chekuchinja nguva uye kuderera kwemuchina, kuvandudza zvakanyanya kuita kwese kugadzirisa.

Yakaderedzwa Vibration uye Kupisa:

Iyo yakagadzika clamping inoderedza kudengenyeka kwechishandiso panguva yekugadzira uye inodzikisa kupisa kunogadzirwa panguva yekucheka. Izvi zvinobatsira kuwedzera hupenyu hwezvishandiso uye kuchengetedza kunaka kwepamusoro.

Kuchinjika kune Zvishandiso Zvakasiyana:

Iyo JT modhi yemudziyo inobata inoenderana nemhando dzakasiyana dzemagayo ekucheka, kunyanya iwo ane marefu kana anochinjika grooves, senge shell end mill uye.masaha. Izvi zvinoita kuti zvive zvakasiyana-siyana kune zvakaoma machining mabasa.

Kushandisa Nzira

Kuisa Tool Holder:

Kwidza iyo JT modhi musanganiswa kumeso chigayo adapta chibatiso pane spindle yemuchina wekugaya. Iva nechokwadi chekubatana kwakasimba pakati pechibatiso chemudziyo uye spindle kudzivirira kusagadzikana.

Kubata iyo Milling Cutter:

1. Sarudza chigayo chakakodzera chekucheka chine longitudinal kana transverse grooves, senge shell end mill kanasaha yekutsemura.

2. Isai shank yeguyo mugomba rekusungirira remuchina weJT, ive nechokwadi chekuti magirosi anoenderana.

3. Shandisa chibatiso chekukiya chemudziyo (somuenzaniso, masiruuru kana nzungu) kusungirira zvakachengetedzeka chinocheka chigayo.

Kugadzirisa Nzvimbo Yechishandiso:

Rongedza urefu hwekuwedzera uye kona yechishandiso zvinoenderana nemachining inoda kuve nechokwadi chekucheka kwakaringana chinzvimbo.

Kutanga Machining:

Mushure mekusimbisa kuti chishandiso chakaiswa zvakachengeteka, tanga muchina wekugaya kuti utange machining process. Iyo inobata chishandiso ichapa yakatsiga rutsigiro kuti ive nechokwadi chepamusoro-chaizvo chekucheka mhedzisiro.

Usage Precautions

Ita shuwa Groove Matching:

Paunenge uchirovera chigayo chekucheka, ita shuwa kuti magirofu emudziyo anoenderana nemagoro pane JT mudziyo unobata. Mispatched grooves inogona kutungamira kune isina kugadzikana clamping, ichikanganisa machining nemazvo uye kuwedzera njodzi dzekuchengetedza.

Kugara Kuongororwa KweMubati Wechishandiso uye Mamiriro Ekushandisa:

Usati washandisa uye mushure mekushandisa, ongorora chibatiso chemudziyo uye chigayo chekucheka chero chakapfeka kana kukuvadzwa. Kana nyaya dzawanikwa, dzitsive kana dzigadzirise nekukasira kuti uone kuvimbika kweiyo clamping system.

Dzivisa Kunyanya Kushandisa:

Tevedzera yakayerwa kuremerwa huwandu hwechibatiso chibatiso uye chishandiso kudzivirira kuishandisa pasi pepamusoro-mutoro mamiriro. Kuwedzeredza kunogona kukonzera deformation yemubati wemidziyo kana kukuvadzwa kwechishandiso, zvichikanganisa kunaka kwemuchina uye hupenyu hwemidziyo.

Chengetedza Hutsanana:

Mushure mekushandisa kwega kwega, chenesa mudziyo wekushandisa uye maturusi ekubvisa machipisi nemarara. Kuchengeta nzvimbo dzekusungirira dzakachena kunobatsira kuchengetedza kuita kwakanaka kwekusunga uye kudzivirira kusagadzikana nekuda kwekuunganidzwa kwetsvina.

Kushanda Kwakakodzera kweKukiya Mechanism:

Paunenge uchikiya chishandiso, shandisa kunyangwe kudzvanywa kuti udzivise kuomesa-kusimbisa kana kuomesa pasi kune rimwe divi. Ita shuwa kuti chishandiso hachifambise kana kudedera panguva yekugadzira machining.

Regulant Maintenance:

Gadzira gadziriso yenguva dzose pane JT mudziyo inobata, kusanganisira kutarisa zvinhu zvinosungirira zve clamping meshini yekuregedzera, uye nemafuta ekufambisa anofamba kuti arambe ari mukushanda kwakanaka. Izvi zvinoita kuti muridzi wemidziyo arambe ari muchimiro chekushanda.