» HSS DIN371 Threading Tap Ka Flute e otlolohileng le e Spiral kapa Spiral Point

DIN371 Threading Tap

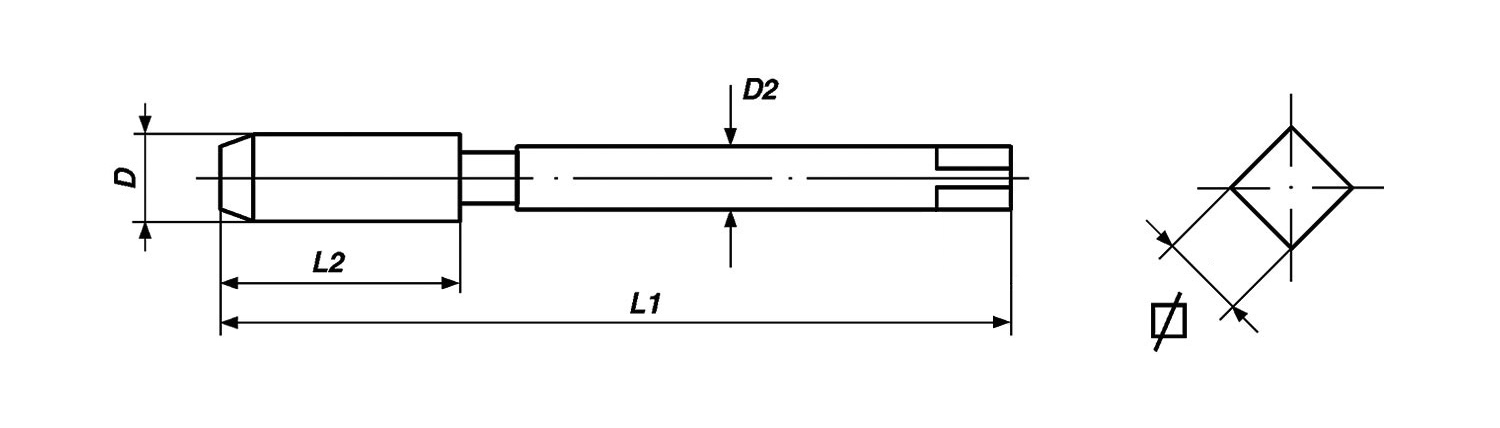

Lebitso la Sehlahisoa: DIN371 Mochini oa Tlanya

Khoele Angle: 60°

Flute: E otlolohileng/ Ntlha ya Spiral/ Flute e bilikang e potlakileng 35º/ Flute e butle-butle 15º

lintho tse bonahalang: HSS/HSSCo5%

Ho roala: E khanyang/ TiN/ TiCN

Lekolilo le Otlolohileng

| KHOLO (D) | KHOELE LENGTH(L2) | KAOFELA LENGTH(L1) | SHANKA DIA.(D2) | LEKAKARE (a) | HSS | HSSCo5% | ||

| E kganyang | TiN | E kganyang | TiN | |||||

| M2×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3818 | 660-3831 | 660-3857 | 660-3870 |

| M2.3×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3819 | 660-3832 | 660-3858 | 660-3871 |

| M2.5×0,45 | 9 | 50 | 2.8 | 2.1 | 660-3820 | 660-3833 | 660-3859 | 660-3872 |

| M2.6×0,45 | 9 | 50 | 2.8 | 2.1 | 660-3821 | 660-3834 | 660-3860 | 660-3873 |

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-3822 | 660-3835 | 660-3861 | 660-3874 |

| M3.5×0.6 | 12 | 56 | 4 | 3 | 660-3823 | 660-3836 | 660-3862 | 660-3875 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-3824 | 660-3837 | 660-3863 | 660-3876 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-3825 | 660-3838 | 660-3864 | 660-3877 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-3826 | 660-3839 | 660-3865 | 660-3878 |

| M7×1 | 17 | 80 | 7 | 5.5 | 660-3827 | 660-3840 | 660-3866 | 660-3879 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-3828 | 660-3841 | 660-3867 | 660-3880 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-3829 | 660-3842 | 660-3868 | 660-3881 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-3830 | 660-3843 | 660-3869 | 660-3882 |

Spiral Point

| KHOLO (D) | KHOELE LENGTH(L2) | KAOFELA LENGTH(L1) | SHANKA DIA.(D2) | LEKAKARE (a) | HSS | HSSCo5% | ||

| E kganyang | TiN | E kganyang | TiN | |||||

| M2×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3896 | 660-3909 | 660-3935 | 660-3948 |

| M2.3×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3897 | 660-3910 | 660-3936 | 660-3949 |

| M2.5×0,45 | 9 | 50 | 2.8 | 2.1 | 660-3898 | 660-3911 | 660-3937 | 660-3950 |

| M2.6×0,45 | 9 | 50 | 2.8 | 2.1 | 660-3899 | 660-3912 | 660-3938 | 660-3951 |

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-3900 | 660-3913 | 660-3939 | 660-3952 |

| M3.5×0.6 | 12 | 56 | 4 | 3 | 660-3901 | 660-3914 | 660-3940 | 660-3953 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-3902 | 660-3915 | 660-3941 | 660-3954 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-3903 | 660-3916 | 660-3942 | 660-3955 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-3904 | 660-3917 | 660-3943 | 660-3956 |

| M7×1 | 17 | 80 | 7 | 5.5 | 660-3905 | 660-3918 | 660-3944 | 660-3957 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-3906 | 660-3919 | 660-3945 | 660-3958 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-3907 | 660-3920 | 660-3946 | 660-3959 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-3908 | 660-3921 | 660-3947 | 660-3960 |

Flute e potlakileng ea Spiral 35º

| KHOLO (D) | KHOELE LENGTH(L2) | KAOFELA LENGTH(L1) | SHANKA DIA.(D2) | LEKAKARE (a) | HSS | HSSCo5% | ||

| E kganyang | TiN | E kganyang | TiN | |||||

| M3×0.5 | 5 | 56 | 3.5 | 2.7 | 660-3974 | 660-3981 | 660-3995 | 660-4002 |

| M4×0.7 | 7 | 63 | 4.5 | 3.4 | 660-3975 | 660-3982 | 660-3996 | 660-4003 |

| M5×0.8 | 8 | 70 | 6 | 4.9 | 660-3976 | 660-3983 | 660-3997 | 660-4004 |

| M6×1 | 10 | 80 | 6 | 4.9 | 660-3977 | 660-3984 | 660-3998 | 660-4005 |

| M8×1.25 | 13 | 90 | 8 | 6.2 | 660-3978 | 660-3985 | 660-3999 | 660-4006 |

| M10×1.5 | 15 | 100 | 10 | 8 | 660-3979 | 660-3986 | 660-4000 | 660-4007 |

| M12×1.75 | 18 | 110 | 12 | 9 | 660-3980 | 660-3987 | 660-4001 | 660-4008 |

Flute e liehang ea 15º

| KHOLO (D) | KHOELE LENGTH(L2) | KAOFELA LENGTH(L1) | SHANKA DIA.(D2) | LEKAKARE (a) | HSS | HSSCo5% | ||

| E kganyang | TiN | E kganyang | TiN | |||||

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-4016 | 660-4023 | 660-4037 | 660-4044 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-4017 | 660-4024 | 660-4038 | 660-4045 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-4018 | 660-4025 | 660-4039 | 660-4046 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-4019 | 660-4026 | 660-4040 | 660-4047 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-4020 | 660-4027 | 660-4041 | 660-4048 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-4021 | 660-4028 | 660-4042 | 660-4049 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-4022 | 660-4029 | 660-4043 | 660-4050 |

Otlolohileng Flute DIN 371 Machine Tap

Kopo: E loketse bakeng sa ho khoasolla sefofu kapa ka masoba a tšepe, tšepe e sa hloekang, tšepe e entsoeng ka tšepe le lisebelisoa tse se nang ferrous. Meno a eona a fatše le chamfer e koahelang likhoele tse 2-3 li etsa hore e loketse botebo ba khoele e ka tlase ho makhetlo a 2 bophara ba pompong (2d1).

Tšebeliso e khothalelitsoeng: Mofuta ona o sebetsa ka ho khetheha bakeng sa ho tlanya ka letsoho ka lebaka la liphala tsa oona tse otlolohileng, tse fanang ka botsitso le boiketlo ba tšebeliso.

Spiral Point DIN 371 Machine Tap

Sesebelisoa: E etselitsoe ho etsa likhoele ka mekoting, pompo ena e na le meno a fatše le chamfer ea likhoele tse 4-5. E sebetsa hantle bakeng sa botebo ba khoele ho fihla makhetlo a 3 ho feta bophara ba pompo (3d1) ka tšepe, tšepe e sa hloekang le tšepe e entsoeng ka tšepe.

Tšebeliso e khothalelitsoeng: The spiral point e sutumelletsa li-chips pele, e etsa hore e be sebaka se loketseng ho feta ka masoba moo ho ntša chip ho leng bonolo.

Fast Spiral Flute 35º DIN 371 Machine Tap

Tšebeliso: Theipi ena e etselitsoe likoti tse foufetseng tsa tšepe, tšepe e sa hloekang, tšepe e entsoeng ka tšepe le lisebelisoa tse se nang ferrous tse nang le khoele e tebileng ka makhetlo a 2.5 ho feta bophara ba pompo (2.5d1). Lekolilo la 35º le potlakang le thusa ho ntša li-chip ka katleho.

Tšebeliso e khothalelitsoeng: E loketse mechini ea CNC moo ho roala ka lebelo le holimo le ho nepahala ho leng bohlokoa.

Butle-butle Flute 15º DIN 371 Mochine oa Tlanya

Tšebeliso: Joalo ka 'moka oa eona o potlakileng oa spiral, pompo ena e sebelisetsoa masoba a foufetseng ka thepa e tšoanang, empa ka moeli oa botebo ba khoele oa makhetlo a 2 bophara ba pompo (2d1). Folute e butle ea 15º e fana ka ho tlosoa ha chip ho laoloang.

Tšebeliso e khothalelitsoeng: E khothaletsoa bakeng sa lisebelisoa tse hlahisang li-chips tse telele, tse likhoele, tse netefatsang ts'ebetso e hloekileng ea likhoele.

Likhetho tsa ho roala

Bright, TiN (Titanium Nitride), TiCN (Titanium Carbonitride): Liaparo tsena li ntlafatsa ho tšoarella ha pompo, ho hanyetsa mocheso, le lubricity, kahoo li eketsa bophelo ba lisebelisoa le ts'ebetso ea lisebelisoa tse fapaneng.

E 'ngoe le e 'ngoe ea lipompo tsena e ka etsoa ka mokhoa o ikhethileng hore e sebelisoe libakeng tse fapaneng tsa mochini, ho latela thepa, mofuta oa lesoba le botebo ba khoele. Ho bohlokoa ho khetha mofuta o nepahetseng oa pompo ea mochini oa DIN 371 bakeng sa sesebelisoa ka seng ho netefatsa ts'ebetso e nepahetseng le bophelo bo bolelele ba sesebelisoa.

Molemo oa ho Tsamaea Tseleng

• Tshebeletso e Sebetsang hantle le e Tshepehang;

• Boleng bo botle;

• Litheko tsa Tlholisano;

• OEM, ODM, OBM;

• Mefuta e mengata e fapaneng

• Phatlalatso e potlakileng le e ka tšeptjoang

Litaba tsa Sephutheloana

1 x DIN371 Mochini oa Tlanya

1 x Nyeoe ea Tšireletso

● Na o hloka OEM, OBM, ODM kapa neutral packing bakeng sa lihlahisoa tsa hau?

● Lebitso la khamphani ea hau le lintlha tsa khokahanyo bakeng sa maikutlo a potlakileng le a nepahetseng.

Ho feta moo, re u mema hore u kope mehlala ea tlhahlobo ea boleng.