» HSS Metric & Inch Dovetail End Mill With 45 And 60 Degree For Industrial

Tlhaloso

Re thabetse hore ebe o khahlisoa ke leloala la rona la dovetail end. The dovetail end mill ke sesebelisoa sa ho seha bakeng sa ho etsa li-dovetail slots le manonyeletso, tse sebelisoang mecheng ea ho sila bakeng sa likhokahano tse nepahetseng.

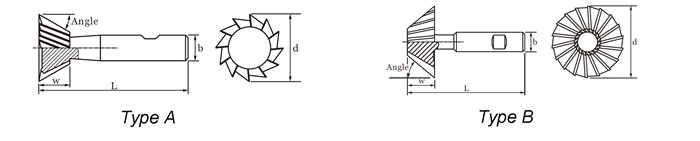

45°, Mofuta oa A, Inche

| MOHLABI DIA.IN | SHANKA DIA. | MOTS'OETSI BOHLALE | KAKARETSO BELELE | HSS | HSS (TiN) |

| 3/8 | 3/8 | 1/8 | 2-1/8 | 660-6216 | 660-6222 |

| 1/2 | 3/8 | 5/32 | 2-1/8 | 660-6217 | 660-6223 |

| 3/4 | 3/8 | 1/4 | 2-1/8 | 660-6218 | 660-6224 |

| 1-3/8 | 5/8 | 7/16 | 2-7/8 | 660-6219 | 660-6225 |

| 1-7/8 | 7/8 | 9/16 | 3-1/4 | 660-6220 | 660-6226 |

| 2-1/4 | 1 | 5/8 | 3-3/4 | 660-6221 | 660-6227 |

45°, Mofuta oa A, Metric

| MOHLABI DIA.IN | SHANKA DIA. | MOTS'OETSI BOHLALE | KAKARETSO BELELE | HSS | HSS (TiN) |

| 13.0 | 12 | 4 | 54 | 660-6228 | 660-6233 |

| 16.0 | 12 | 4 | 60 | 660-6229 | 660-6234 |

| 19.0 | 12 | 5 | 63 | 660-6230 | 660-6235 |

| 25.0 | 12 | 6.3 | 67 | 660-6231 | 660-6236 |

| 32.0 | 16 | 8 | 71 | 660-6232 | 660-6237 |

60°,Mofuta oa A, Boholo ba Inch

| MOHLABI DIA.IN | SHANKA DIA. | MOTS'OETSI BOHLALE | KAKARETSO BELELE | HSS | HSS (TiN) |

| 3/8 | 3/8 | 3/16 | 2-1/8 | 660-6238 | 660-6244 |

| 1/2 | 3/8 | 1/4 | 2-1/8 | 660-6239 | 660-6245 |

| 3/4 | 3/8 | 5/16 | 2-1/8 | 660-6240 | 660-6246 |

| 1-3/8 | 5/8 | 9/16 | 2-7/8 | 660-6241 | 660-6247 |

| 1-7/8 | 7/8 | 13/16 | 3-1/4 | 660-6242 | 660-6248 |

| 2-1/4 | 1 | 1-1/16 | 3-3/4 | 660-6243 | 660-6249 |

60°,Mofuta oa A, Metric Size

| MOHLABI DIA.IN | SHANKA DIA. | MOTS'OETSI BOHLALE | KAKARETSO BELELE | HSS | HSS (TiN) |

| 13.0 | 12 | 5.8 | 54 | 660-6250 | 660-6255 |

| 16.0 | 12 | 6.3 | 60 | 660-6251 | 660-6256 |

| 19.0 | 12 | 8 | 63 | 660-6252 | 660-6257 |

| 25.0 | 12 | 10 | 67 | 660-6253 | 660-6258 |

| 32.0 | 16 | 12.5 | 71 | 660-6254 | 660-6259 |

45°,Mofuta oa B, Boholo ba Inch

| MOHLABI DIA.IN | SHANKA DIA. | MOTS'OETSI BOHLALE | KAKARETSO BELELE | HSS | HSS (TiN) |

| 1 | 1/2 | 5/16 | 2-3/4 | 660-6260 | 660-6262 |

| 1-1/2 | 1 | 13/32 | 3-5/32 | 660-6261 | 660-6263 |

45°,Mofuta oa B, Metric Size

| MOHLABI DIA.IN | SHANKA DIA. | MOTS'OETSI BOHLALE | KAKARETSO BELELE | HSS | HSS (TiN) |

| 13 | 12 | 3.7 | 58 | 660-6264 | 660-6272 |

| 16 | 12 | 4 | 66.5 | 660-6265 | 660-6273 |

| 19.0 | 12 | 5.5 | 6.5 | 660-6266 | 660-6274 |

| 20.0 | 12 | 5 | 63 | 660-6267 | 660-6275 |

| 22.0 | 12 | 7.5 | 68.5 | 660-6268 | 660-6276 |

| 25.0 | 12 | 8.5 | 70 | 660-6269 | 660-6277 |

| 28.0 | 16 | 8.5 | 71.5 | 660-6270 | 660-6278 |

| 32.0 | 16 | 8.5 | 74.5 | 660-6271 | 660-6279 |

60°,Mofuta oa B, Boholo ba Inch

| MOHLABI DIA.IN | SHANKA DIA. | MOTS'OETSI BOHLALE | KAKARETSO BELELE | HSS | HSS (TiN) |

| 1 | 1/2 | 15/32 | 2-3/4 | 660-6280 | 660-6282 |

| 1-1/2 | 1 | 5/8 | 3-3/8 | 660-6281 | 660-6283 |

60°,Mofuta oa B, Metric Size

| MOHLABI DIA.IN | SHANKA DIA. | MOTS'OETSI BOHLALE | KAKARETSO BELELE | HSS | HSS (TiN) |

| 13 | 12 | 4.3 | 58 | 660-6284 | 660-6292 |

| 16 | 12 | 5.5 | 66.5 | 660-6285 | 660-6293 |

| 19 | 12 | 7 | 6.5 | 660-6286 | 660-6294 |

| 20 | 12 | 8 | 63 | 660-6287 | 660-6295 |

| 22 | 12 | 12 | 68.5 | 660-6288 | 660-6296 |

| 25 | 12 | 12.5 | 70 | 660-6289 | 660-6297 |

| 28 | 16 | 13.5 | 71.5 | 660-6290 | 660-6298 |

| 32 | 16 | 13.5 | 74.5 | 660-6291 | 660-6299 |

Kopo

Mesebetsi ea Dovetail End Mill:

1. Ho pota-pota:Ho cheka likhutlo tse hlabang tsa mochini oa ho sebetsa likhutlong tse chitja ho fokotsa khatello ea maikutlo, ka hona ho ntlafatsa matla le ho tšoarella ha sesebelisoa.

2. Ho qeta bokaholimo:Ho matlafatsa botle le maikutlo a sebaka sa mosebetsi, ho qoba likotsi tse ka bang teng ho tsoa metseng e bohale.

3. Ntlafatso ea polokeho:Ho fokotsa kotsi ea ho ba le mengopo le makhopho ho sesebelisoa sa mosebetsi nakong ea ts'ebeliso le ho ts'oaroa.

Tšebeliso Bakeng sa Dovetail End Mill:

1. Ho khetha sesebelisoa se nepahetseng:Khetha Corner Rounding End Mill e loketseng ho latela thepa ea sesebedisoa le radius e hlokahalang ea sekhutlo.

2. Tokiso ea mosebetsi:Netefatsa hore workpiece e tsitsitse ka mokhoa o sireletsehileng holim'a tafole ea ho sebetsa ho thibela ho sisinyeha kapa ho sisinyeha nakong ea mochini.

3. Ho beha litekanyetso tsa mochini: Beha lebelo le nepahetseng la ho itšeha le sekhahla sa phepelo. Lebelo la ho itšeha le sekhahla sa phepelo se lokela ho fetoloa ho latela thepa ea sesebediswa, bophara ba sesebelisoa le lisebelisoa tsa lisebelisoa.

4. Ho qala mochini: Qala mochine 'me butle-butle u tsamaise sesebelisoa ho ea moeling oa workpiece bakeng sa machining a sekhutlo.

5. Ho pholisa le ho tlotsa: Sebelisa oli e pholileng kapa e tlotsang nakong ea mochini ho fokotsa moaparo oa lisebelisoa le ho ntlafatsa boleng ba mochini.

6. Ho hlahloba liphetho tsa mochini: Ka mor'a hore machining a phethoe, hlahloba hore na likhutlo tsa workpiece li finyella litlhoko le ho etsa litokiso ha ho hlokahala.

Litlhokomelo Bakeng sa Dovetail End Mill:

1. Khetho ea lisebelisoa:Khetha lisebelisoa tse nepahetseng tsa lisebelisoa (tse kang tšepe e phahameng ka lebelo kapa carbide) le bophara ba sesebelisoa ho latela thepa ea mosebetsi le litlhoko tsa machining.

2. Litlhophiso tsa ho khaola: Beha lebelo le nepahetseng la ho itšeha le sekhahla sa phepelo ho qoba ho senyeha ho feteletseng ha sesebelisoa kapa mathata a boleng ba mochini.

3. Tokiso ea mosebetsi:Netefatsa hore workpiece e tsitsitse ka thata ho thibela ho falla kapa ho thothomela nakong ea machining, e amang ho nepahala ha mochini.

4. Ho pholisa le ho tlotsa: Sebelisa sepholi se loketseng kapa oli e tlotsang ho fokotsa mocheso o khathollang le ho roala ha lisebelisoa, ho lelefatsa bophelo ba lisebelisoa.

5. Ts'ebetso ea polokeho:Apara lisebelisoa tse nepahetseng tsa ts'ireletso nakong ea ts'ebetso ho thibela likotsi tse tsoang ho maloanlahla a mochini kapa likotsi tse ling.

Molemo

Tšebeletso e Sebetsang hantle le e Tšepahalang

Lisebelisoa tsa Wayleading, morekisi oa hau oa sebaka se le seng bakeng sa lisebelisoa tsa ho seha, lisebelisoa tsa mochini, lisebelisoa tsa ho lekanya. Joalo ka setsi se kopaneng sa matla a indasteri, re motlotlo haholo ka Ts'ebeletso ea rona e Sebetsang le e Tšepahalang, e etselitsoeng ho fihlela litlhoko tse fapaneng tsa bareki ba rona ba hlomphuoang. Tobetsa Mona Bakeng sa Tse ling

Boleng bo Botle

Ho Lisebelisoa tsa Wayleading, boitlamo ba rona ba Boleng bo Botle bo re khetholla re le matla a maholo indastering. Joaloka setsi sa motlakase se kopantsoeng, re fana ka mefuta e fapaneng ea litharollo tsa indasteri tse tsoetseng pele, tse u fang lisebelisoa tse ntlehali tsa ho itšeha, lisebelisoa tse nepahetseng tsa ho lekanya, le lisebelisoa tse tšepahalang tsa mochini.TobetsaMona Bakeng sa Tse ling

Litheko tsa tlhōlisano

Rea u amohela ho Wayleading Tools, morekisi oa hau o le mong bakeng sa lisebelisoa tsa ho itšeha, lisebelisoa tsa ho lekanya, lisebelisoa tsa mochini. Re motlotlo haholo ka ho fana ka Litheko tsa Tlholisano e le o mong oa melemo ea rona ea mantlha. Tobetsa Mona ho Fumana Tse ling

OEM, ODM, OBM

Ho Lisebelisoa tsa Wayleading, re motlotlo ka ho fana ka lits'ebeletso tse felletseng tsa OEM (Moetsi oa Lisebelisoa tsa Original), ODM (Original Design Manufacturer), le OBM (Own Brand Manufacturer), tse fanang ka litlhoko le mehopolo ea hau e ikhethang.Tobetsa Mona Bakeng sa Tse ling

Mefuta e sa tšoaneng e Atolositsoeng

Rea u amohela ho Wayleading Tools, sebaka seo u eang ho sona bakeng sa litharollo tsa morao-rao tsa indasteri, moo re ipabolang ka ho seha lisebelisoa, lisebelisoa tsa ho metha, le lisebelisoa tsa mochini. Monyetla oa rona oa mantlha ke ho fana ka mefuta e mengata e fapaneng ea lihlahisoa, e etselitsoeng ho fihlela litlhoko tse fapaneng tsa bareki ba rona ba hlomphuoang.Tobetsa Mona Bakeng sa Tse ling

Lintho tse Tšoanang

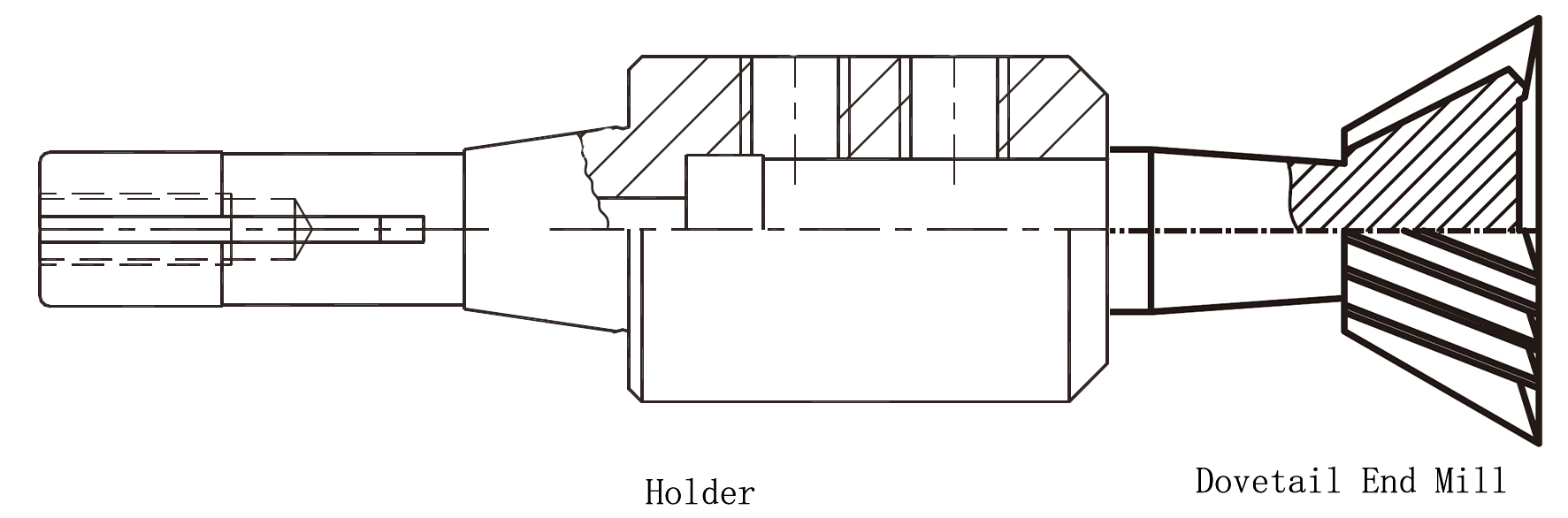

Sets'oants'o se Tšoanang:Mochini oa ho sila oa R8, mochini oa ho roala BT, mochini oa ho roala mochini oa MT, mochini oa ho roala mochini oa NT.

Tharollo

Tšehetso ea tekheniki:

Re thabetse ho ba mofani oa hau oa tharollo bakeng sa ER collet. Re thabela ho u fa tšehetso ea tekheniki. Ebang ke nakong ea thekiso ea hau kapa ts'ebeliso ea bareki ba hau, ha re fumana lipotso tsa hau tsa tekheniki, re tla araba lipotso tsa hau hanghang. Re tšepisa ho araba nakong ea lihora tse 24 haufinyane, re u fa litharollo tsa tekheniki.Tobetsa Mona Bakeng sa Tse ling

Litšebeletso tse ikhethileng:

Re thabela ho u fa litšebeletso tse ikhethileng bakeng sa ER collet. Re ka fana ka litšebeletso tsa OEM, lihlahisoa tsa tlhahiso ho latela litšoantšo tsa hau; Litšebeletso tsa OBM, ho hlahisa lihlahisoa tsa rona ka letšoao la hau; le lits'ebeletso tsa ODM, ho fetola lihlahisoa tsa rona ho latela litlhoko tsa moralo oa hau. Ho sa tsotellehe hore na u hloka litšebeletso life, re tšepisa ho u fa litharollo tsa profeshenale.Tobetsa Mona Bakeng sa Tse ling

Litšebeletso tsa Koetliso:

Hore na o moreki oa lihlahisoa tsa rona kapa u mosebelisi oa ho qetela, re thabela ho fana ka ts'ebeletso ea koetliso ho netefatsa hore u sebelisa lihlahisoa tseo u li rekileng ho rona ka nepo. Lisebelisoa tsa rona tsa koetliso li tla ka litokomane tsa elektroniki, livideo le liboka tsa marang-rang, tse u lumellang ho khetha khetho e loketseng ka ho fetisisa. Ho tloha kopo ea hau ea koetliso ho isa ho phano ea litharollo tsa koetliso, re ts'episa ho phethela ts'ebetso eohle nakong ea matsatsi a 3 Tobetsa Mona Bakeng sa Tse ling

Tšebeletso ka mor'a thekiso:

Lihlahisoa tsa rona li tla le nako ea tšebeletso ea likhoeli tse 6 ka mor'a thekiso. Nakong ena, mathata leha e le afe a sa hlahisoang ka boomo a tla nkeloa sebaka kapa a lokisoe ntle ho tefo. Re fana ka ts'ehetso ea litšebeletso tsa bareki bosiu le motšehare, ho sebetsana le lipotso kapa litletlebo life kapa life, ho netefatsa hore u na le boiphihlelo bo monate ba ho reka. Tobetsa Mona Bakeng sa Tse ling

Moralo oa Tharollo:

Ka ho fana ka moralo oa sehlahisoa sa hau sa machining (kapa ho thusa ho theha litšoantšo tsa 3D haeba li sa fumanehe), litlhaloso tsa thepa, le lintlha tsa mochini tse sebelisitsoeng, sehlopha sa rona sa sehlahisoa se tla hlophisa likhothaletso tse loketseng bakeng sa lisebelisoa tsa ho seha, lisebelisoa tsa mochini le lisebelisoa tsa ho lekanya, le ho rala litharollo tse felletseng tsa machining. molemong oa hau. Tobetsa Mona Bakeng sa Tse ling

Ho paka

E phuthetsoe ka lebokoseng la polasetiki. Ebe e kenngoa ka lebokoseng le ka ntle. E ka sireletsa hantle leloala la dovetail end. Hape ho phutheloa ka mokhoa o ikhethileng ho amoheloa.

● Na o hloka OEM, OBM, ODM kapa neutral packing bakeng sa lihlahisoa tsa hau?

● Lebitso la khamphani ea hau le lintlha tsa khokahanyo bakeng sa maikutlo a potlakileng le a nepahetseng.

Ho feta moo, re u mema hore u kope mehlala ea tlhahlobo ea boleng.