» HSS Shell End Mill Cutter E Nang le Bright & TiN Kapa TialN Coated

Shell End Mill Cutter

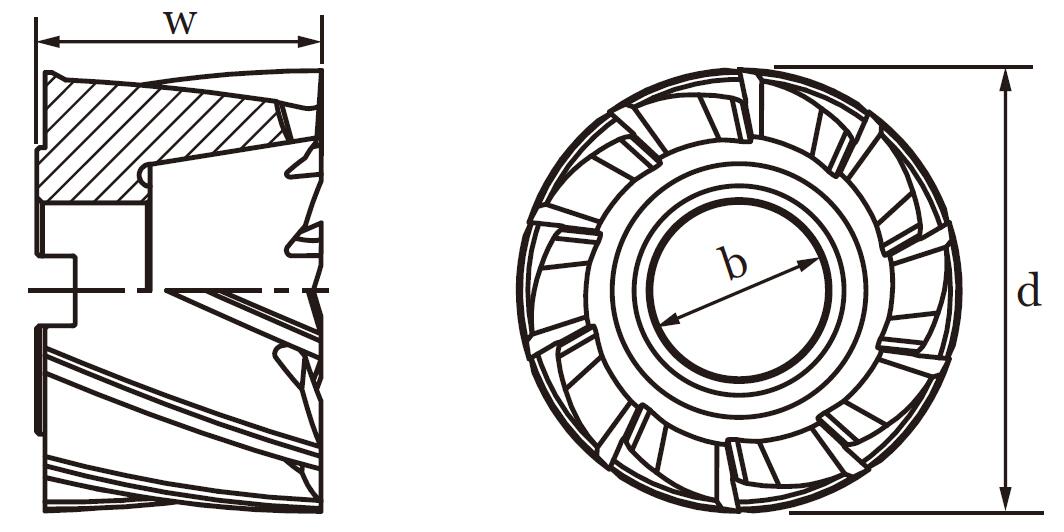

Re thabetse hore ebe u thahasella leloala la rona la ho qetela la likhetla. Leloala la ho qetela la khetla ke sesebelisoa sa tšepe se sebelisoang hangata se sebelisoang haholo tšimong ea machining. Ho fapana le tshilo e tiileng ya ho qetela, tshilo ya kgetla e na le hlooho e sehang e ka nkelwang sebaka le shank e tsitsitseng.

Metric

| KHOLO MM | SEKOBA DIA. | BELELE TS'ELISO LEKHOA | LEHLAKOANA NO. | HSS | HSSCo5% | HSSCo8% | ||||||

| E kganyang | TiN | TiAlN | E kganyang | TiN | TiAlN | E kganyang | TiN | TiAlN | ||||

| 40 | 16 | 32 | 6 | 660-5020 | 660-5027 | 660-5034 | 660-5041 | 660-5048 | 660-5055 | 660-5062 | 660-5069 | 660-5076 |

| 50 | 22 | 36 | 8 | 660-5021 | 660-5028 | 660-5035 | 660-5042 | 660-5049 | 660-5056 | 660-5063 | 660-5070 | 660-5077 |

| 63 | 27 | 40 | 8 | 660-5022 | 660-5029 | 660-5036 | 660-5043 | 660-5050 | 660-5057 | 660-5064 | 660-5071 | 660-5078 |

| 80 | 27 | 45 | 10 | 660-5023 | 660-5030 | 660-5037 | 660-5044 | 660-5051 | 660-5058 | 660-5065 | 660-5072 | 660-5079 |

| 100 | 32 | 50 | 10 | 660-5024 | 660-5031 | 660-5038 | 660-5045 | 660-5052 | 660-5059 | 660-5066 | 660-5073 | 660-5080 |

| 125 | 40 | 56 | 12 | 660-5025 | 660-5032 | 660-5039 | 660-5046 | 660-5053 | 660-5060 | 660-5067 | 660-5074 | 660-5081 |

| 160 | 50 | 63 | 16 | 660-5026 | 660-5033 | 660-5040 | 660-5047 | 660-5054 | 660-5061 | 660-5068 | 660-5075 | 660-5082 |

| 660-5083 | ||||||||||||

Intshi

| KHOLO IN | SEKOBA DIA. | BELELE TS'ELISO LEKHOA | LEHLAKOANA NO. | HSS | HSSCo5% | HSSCo8% | ||||||

| 1-1/4 | 1 | 1/2 | 8 | E kganyang | TiN | TiAlN | E kganyang | TiN | TiAlN | E kganyang | TiN | TiAlN |

| 1-1/2 | 1-1/8 | 1/2 | 8 | 660-5083 | 660-5096 | 660-5109 | 660-5122 | 660-5135 | 660-5148 | 660-5161 | 660-5174 | 660-5187 |

| 1-3/4 | 1-1/4 | 3/4 | 8 | 660-5084 | 660-5097 | 660-5110 | 660-5123 | 660-5136 | 660-5149 | 660-5162 | 660-5175 | 660-5188 |

| 2 | 1-3/8 | 3/4 | 10 | 660-5085 | 660-5098 | 660-5111 | 660-5124 | 660-5137 | 660-5150 | 660-5163 | 660-5176 | 660-5189 |

| 2-1/4 | 1-1/2 | 1 | 10 | 660-5086 | 660-5099 | 660-5112 | 660-5125 | 660-5138 | 660-5151 | 660-5164 | 660-5177 | 660-5190 |

| 2-1/2 | 1-5/8 | 1 | 10 | 660-5087 | 660-5100 | 660-5113 | 660-5126 | 660-5139 | 660-5152 | 660-5165 | 660-5178 | 660-5191 |

| 2-3/4 | 1-5/8 | 1 | 10 | 660-5088 | 660-5101 | 660-5114 | 660-5127 | 660-5140 | 660-5153 | 660-5166 | 660-5179 | 660-5192 |

| 3 | 1-3/4 | 1-1/4 | 12 | 660-5089 | 660-5102 | 660-5115 | 660-5128 | 660-5141 | 660-5154 | 660-5167 | 660-5180 | 660-5193 |

| 3-1/2 | 1-7/8 | 1-1/4 | 12 | 660-5090 | 660-5103 | 660-5116 | 660-5129 | 660-5142 | 660-5155 | 660-5168 | 660-5181 | 660-5194 |

| 4 | 2-1/4 | 1-1/2 | 14 | 660-5091 | 660-5104 | 660-5117 | 660-5130 | 660-5143 | 660-5156 | 660-5169 | 660-5182 | 660-5195 |

| 4-1/2 | 2-1/4 | 1-1/2 | 14 | 660-5092 | 660-5105 | 660-5118 | 660-5131 | 660-5144 | 660-5157 | 660-5170 | 660-5183 | 660-5196 |

| 5 | 2-1/4 | 1-1/2 | 16 | 660-5093 | 660-5106 | 660-5119 | 660-5132 | 660-5145 | 660-5158 | 660-5171 | 660-5184 | 660-5197 |

| 6 | 2-1/4 | 2 | 16 | 660-5094 | 660-5107 | 660-5120 | 660-5133 | 660-5146 | 660-5159 | 660-5172 | 660-5185 | 660-5198 |

| 6 | 2-1/4 | 2 | 18 | 660-5095 | 660-5108 | 660-5121 | 660-5134 | 660-5147 | 660-5160 | 660-5173 | 660-5186 | 660-5199 |

Kopo

Mesebetsi ea Shell End Mill:

1. Plane Milling: E sebelisetsoa ho etsa machining a libaka tse fapaneng tse bataletseng ho netefatsa hore bokaholimo bo bataletse.

2.Step Milling:E sebelisoa bakeng sa machining mehato ea holim'a metsi, ho finyella sebopeho se lakatsehang sa geometri sa karolo.

3.Slot Milling:E sebelisoa bakeng sa li-slots tsa ho sila tsa libopeho le boholo bo fapaneng.

4.Angle Milling: E sebelisoa bakeng sa machining angled surfaces ho fihlela litlhoko tse khethehileng tsa moralo.

5.Complex Shape Milling: Ka libopeho tse fapaneng tsa lihlooho tsa sehahi, li-profiles tse rarahaneng li ka etsoa.

Tšebeliso Bakeng sa Mesebetsi ea Shell End Mill:

1. Khetha Hlooho le Shank e Loketseng: Khetha hlooho e loketseng ea sehahi le shank e ipapisitseng le lisebelisoa tsa mosebetsi le litlhoko tsa machining.

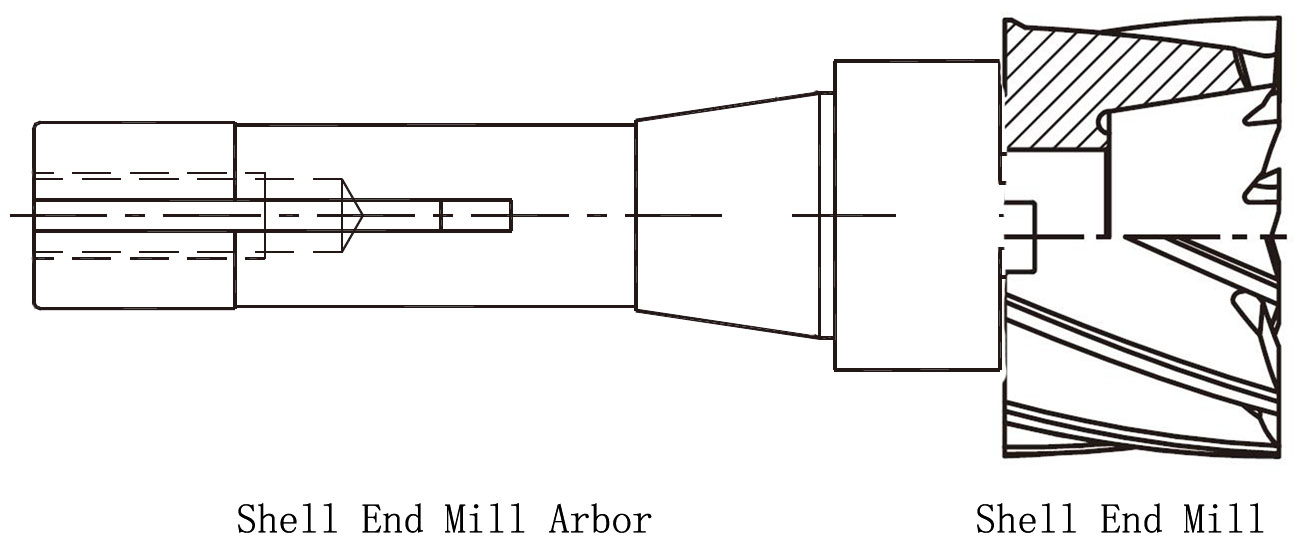

2.Kenya Hlooho ea Cutter:Beha hlooho ea sehaho holim'a shank, ho netefatsa hore e tiisitsoe ka mokhoa o sireletsehileng, hangata o sebelisa liboutu, linotlolo, kapa mekhoa e meng ea khokahano.

3.Kena ka Mochini:Kenya leloala la ho qetela la khetla holim'a mokokotlo oa mochini o silang kapa mochini oa CNC.

4.Beha Litlhophiso:Beha lebelo le nepahetseng la ho itšeha, sekhahla sa phepelo, le botebo ba ho itšeha ho latela thepa e ntseng e etsoa le litšobotsi tsa sesebelisoa.

5.Qala Machining: Qala mochini ho qala machining, 'me u shebe ts'ebetso ea machining ho netefatsa ho itšeha hamonate.

Litlhokomelo Bakeng sa Mesebetsi ea Shell End Mill:

1. Ts'ebetso ea Ts'ireletso:Apara likhalase tse sireletsang le lisebelisoa tse ling tse hlokahalang tsa tšireletso ho qoba ho tsoa likotsi tse tsoang lipacheng tse fofang.

2.Tšireletso ea lisebelisoa:Netefatsa hore hlooho le shank li hokahane ka mokhoa o sireletsehileng ho thibela ho lokoloha ho ka bakang likotsi tsa machining.

3.Ho khaola li-Parameters:Beha litekanyo tsa ho itšeha ka mokhoa o utloahalang ho qoba tšenyo ea sesebelisoa kapa boleng bo tlase ba sesebediswa ka lebaka la lebelo le phahameng haholo la ho itšeha le sekhahla sa phepelo.

4.Ho Pholisa le ho Tlatsa:Khetha mokhoa o nepahetseng oa ho pholisa le ho tlotsa o ipapisitse le thepa e ntseng e etsoa le maemo a ho itšeha ho lelefatsa bophelo ba sesebelisoa le ho ntlafatsa boleng ba mochini.

5.Tlhahlobo ea Kamehla:Kamehla hlahloba sesebelisoa sa ho roala 'me u nkele lihlooho tsa seha tse sehang sebaka ka potlako ho etsa bonnete ba hore mochini o sebetsa hantle le ho sebetsa hantle.

6.Ho sebetsana le Chip:Hloekisa li-chips tse hlahisitsoeng ka nako nakong ea mochini ho thibela chip buildup ho ama ts'ebetso ea mochini kapa ho senya sesebelisoa.

7.Polokelo e Nepahetseng: Ha e sa sebelisoe, boloka leloala la khetla sebakeng se omileng le se hloekileng ho thibela mafome le tšenyo.

Molemo

Tšebeletso e Sebetsang hantle le e Tšepahalang

Lisebelisoa tsa Wayleading, morekisi oa hau oa sebaka se le seng bakeng sa lisebelisoa tsa ho seha, lisebelisoa tsa mochini, lisebelisoa tsa ho lekanya. Joalo ka setsi se kopaneng sa matla a indasteri, re motlotlo haholo ka Ts'ebeletso ea rona e Sebetsang le e Tšepahalang, e etselitsoeng ho fihlela litlhoko tse fapaneng tsa bareki ba rona ba hlomphuoang. Tobetsa Mona Bakeng sa Tse ling

Boleng bo Botle

Ho Lisebelisoa tsa Wayleading, boitlamo ba rona ba Boleng bo Botle bo re khetholla re le matla a maholo indastering. Joaloka setsi sa motlakase se kopantsoeng, re fana ka mefuta e fapaneng ea litharollo tsa indasteri tse tsoetseng pele, tse u fang lisebelisoa tse ntlehali tsa ho itšeha, lisebelisoa tse nepahetseng tsa ho lekanya, le lisebelisoa tse tšepahalang tsa mochini.TobetsaMona Bakeng sa Tse ling

Litheko tsa tlhōlisano

Rea u amohela ho Wayleading Tools, morekisi oa hau o le mong bakeng sa lisebelisoa tsa ho itšeha, lisebelisoa tsa ho lekanya, lisebelisoa tsa mochini. Re motlotlo haholo ka ho fana ka Litheko tsa Tlholisano e le o mong oa melemo ea rona ea mantlha. Tobetsa Mona ho Fumana Tse ling

OEM, ODM, OBM

Ho Lisebelisoa tsa Wayleading, re motlotlo ka ho fana ka lits'ebeletso tse felletseng tsa OEM (Moetsi oa Lisebelisoa tsa Original), ODM (Original Design Manufacturer), le OBM (Own Brand Manufacturer), tse fanang ka litlhoko le mehopolo ea hau e ikhethang.Tobetsa Mona Bakeng sa Tse ling

Mefuta e sa tšoaneng e Atolositsoeng

Rea u amohela ho Wayleading Tools, sebaka seo u eang ho sona bakeng sa litharollo tsa morao-rao tsa indasteri, moo re ipabolang ka ho seha lisebelisoa, lisebelisoa tsa ho metha, le lisebelisoa tsa mochini. Monyetla oa rona oa mantlha ke ho fana ka mefuta e mengata e fapaneng ea lihlahisoa, e etselitsoeng ho fihlela litlhoko tse fapaneng tsa bareki ba rona ba hlomphuoang.Tobetsa Mona Bakeng sa Tse ling

Lintho tse Tšoanang

E tsamaellanang le Shell End Mill Arbor: R8 Shell End Mill, BT Shell End Mill, MT Shell End Mill, NT Shell End Mill

Tharollo

Tšehetso ea tekheniki:

Re thabetse ho ba mofani oa hau oa tharollo bakeng sa ER collet. Re thabela ho u fa tšehetso ea tekheniki. Ebang ke nakong ea thekiso ea hau kapa ts'ebeliso ea bareki ba hau, ha re fumana lipotso tsa hau tsa tekheniki, re tla araba lipotso tsa hau hanghang. Re tšepisa ho araba nakong ea lihora tse 24 haufinyane, re u fa litharollo tsa tekheniki.Tobetsa Mona Bakeng sa Tse ling

Litšebeletso tse ikhethileng:

Re thabela ho u fa litšebeletso tse ikhethileng bakeng sa ER collet. Re ka fana ka litšebeletso tsa OEM, lihlahisoa tsa tlhahiso ho latela litšoantšo tsa hau; Litšebeletso tsa OBM, ho hlahisa lihlahisoa tsa rona ka letšoao la hau; le lits'ebeletso tsa ODM, ho fetola lihlahisoa tsa rona ho latela litlhoko tsa moralo oa hau. Ho sa tsotellehe hore na u hloka litšebeletso life, re tšepisa ho u fa litharollo tsa profeshenale.Tobetsa Mona Bakeng sa Tse ling

Litšebeletso tsa Koetliso:

Hore na o moreki oa lihlahisoa tsa rona kapa u mosebelisi oa ho qetela, re thabela ho fana ka ts'ebeletso ea koetliso ho netefatsa hore u sebelisa lihlahisoa tseo u li rekileng ho rona ka nepo. Lisebelisoa tsa rona tsa koetliso li tla ka litokomane tsa elektroniki, livideo le liboka tsa marang-rang, tse u lumellang ho khetha khetho e loketseng ka ho fetisisa. Ho tloha kopo ea hau ea koetliso ho isa ho phano ea litharollo tsa koetliso, re ts'episa ho phethela ts'ebetso eohle nakong ea matsatsi a 3 Tobetsa Mona Bakeng sa Tse ling

Tšebeletso ka mor'a thekiso:

Lihlahisoa tsa rona li tla le nako ea tšebeletso ea likhoeli tse 6 ka mor'a thekiso. Nakong ena, mathata leha e le afe a sa hlahisoang ka boomo a tla nkeloa sebaka kapa a lokisoe ntle ho tefo. Re fana ka ts'ehetso ea litšebeletso tsa bareki bosiu le motšehare, ho sebetsana le lipotso kapa litletlebo life kapa life, ho netefatsa hore u na le boiphihlelo bo monate ba ho reka. Tobetsa Mona Bakeng sa Tse ling

Moralo oa Tharollo:

Ka ho fana ka moralo oa sehlahisoa sa hau sa machining (kapa ho thusa ho theha litšoantšo tsa 3D haeba li sa fumanehe), litlhaloso tsa thepa, le lintlha tsa mochini tse sebelisitsoeng, sehlopha sa rona sa sehlahisoa se tla hlophisa likhothaletso tse loketseng bakeng sa lisebelisoa tsa ho seha, lisebelisoa tsa mochini le lisebelisoa tsa ho lekanya, le ho rala litharollo tse felletseng tsa machining. molemong oa hau. Tobetsa Mona Bakeng sa Tse ling

Ho paka

E phuthetsoe ka lebokoseng la polasetiki. Ebe e kenngoa ka lebokoseng le ka ntle. E ka sireletsa hantle leloala la khetla. Hape ho phutheloa ka mokhoa o ikhethileng ho amoheloa.

● Na o hloka OEM, OBM, ODM kapa neutral packing bakeng sa lihlahisoa tsa hau?

● Lebitso la khamphani ea hau le lintlha tsa khokahanyo bakeng sa maikutlo a potlakileng le a nepahetseng.

Ho feta moo, re u mema hore u kope mehlala ea tlhahlobo ea boleng.