» Mofuta oa G Arc Pointed Tree Tungsten Carbide Rotary Burr

Mofuta oa G Arc Pointed Tree Tungsten Carbide Rotary Burr

● Ho Seha: Single, Double, Diamond, Alu Cuts

● Coating: Could Coate by TiAlN

Metric

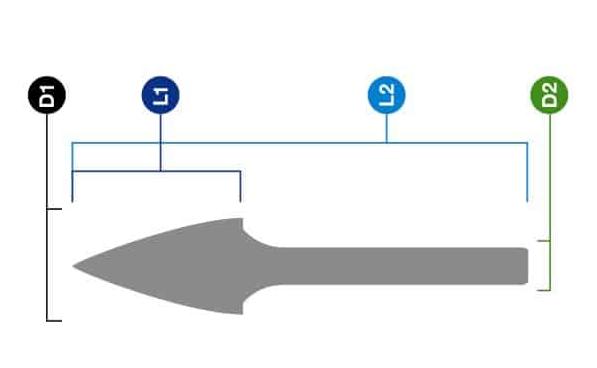

| Mohlala | D1 | L1 | L2 | D2 | Sekha se le Mong | Khaola Habeli | Sekha sa Taemane | Alu Cut |

| G0307 | 3 | 7 | 40 | 3 | 660-3051 | 660-3058 | 660-3065 | 660-3072 |

| G0313 | 3 | 11 | 40 | 3 | 660-3052 | 660-3059 | 660-3066 | 660-3073 |

| G0613 | 6 | 13 | 43 | 3 | 660-3053 | 660-3060 | 660-3067 | 660-3074 |

| G0618 | 6 | 18 | 50 | 6 | 660-3054 | 660-3061 | 660-3068 | 660-3075 |

| G1020 | 10 | 20 | 60 | 6 | 660-3055 | 660-3062 | 660-3069 | 660-3076 |

| G1225 | 12 | 25 | 65 | 6 | 660-3056 | 660-3063 | 660-3070 | 660-3077 |

| G1630 | 16 | 30 | 70 | 6 | 660-3057 | 660-3064 | 660-3071 | 660-3078 |

Intshi

| Mohlala | D1 | L1 | D2 | Sekha se le Mong | Khaola Habeli | Sekha sa Taemane | Alu Cut |

| SG-41 | 1/8" | 1/4" | 1/8" | 660-3454 | 660-3465 | 660-3476 | 660-3487 |

| SG-42 | 1/8" | 5/16" | 1/8" | 660-3455 | 660-3466 | 660-3477 | 660-3488 |

| SG-43 | 1/8" | 3/8" | 1/8" | 660-3456 | 660-3467 | 660-3478 | 660-3489 |

| SG-1 | 1/4" | 5/8" | 1/4" | 660-3457 | 660-3468 | 660-3479 | 660-3490 |

| SG-2 | 5/16" | 3/4" | 1/4" | 660-3458 | 660-3469 | 660-3480 | 660-3491 |

| SG-3 | 3/8" | 3/4" | 1/4" | 660-3459 | 660-3470 | 660-3481 | 660-3492 |

| SG-4 | 1/2" | 3/4" | 1/4" | 660-3460 | 660-3471 | 660-3482 | 660-3493 |

| SG-5 | 1/2" | 1" | 1/4" | 660-3461 | 660-3472 | 660-3483 | 660-3494 |

| SG-6 | 5/8" | 1" | 1/4" | 660-3462 | 660-3473 | 660-3484 | 660-3495 |

| SG-7 | 3/4" | 1" | 1/4" | 660-3463 | 660-3474 | 660-3485 | 660-3496 |

| SG-15 | 3/4" | 1-1/2" | 1/4" | 660-3464 | 660-3475 | 660-3486 | 660-3497 |

Metal Fabrication Ka katleho

Tungsten Carbide Rotary Burrs ke ea bohlokoa indastering ea ho sebetsa ka tšepe, e tumme ka ts'ebeliso ea eona e fapaneng le ts'ebetso e phahameng ea mesebetsi e mengata. Likarolo tsa bona tsa bohlokoa li akaretsa.

Kalafo ea ho Deburring le Welding: Li-burrs tsena li bohlokoa haholo ha ho etsoa tšepe bakeng sa bokhoni ba tsona ba ho tlosa li-burrs tse entsoeng nakong ea ho tjheseletsa kapa ho itšeha, ka lebaka la ho thatafala ha tsona le ho se mamelle. Sena se etsa hore e be tse nepahetseng bakeng sa ts'ebetso ea ho tlosa chelete ka nepo.

Nepahetseng ka ho Sepa le ho Betla

Shaping le Engraving: Tungsten Carbide Rotary Burrs ke ea bohlokoa ka lebaka la ho nepahala ha tsona ho bōpeng, ho betla le ho fokotsa likarolo tsa tšepe. Ba na le tsebo ea ho sebetsana le mefuta e fapaneng ea mefuta ea tšepe, ho kenyeletsoa empa e sa felle feela ho li-alloys tse thata le lisebelisoa tsa aluminium.

Ts'ebetso ea ho sila le ho benya

Ho sila le ho bentša: Karolong ea ts'ebetso ea tšepe e nepahetseng, li-burrs tsena li bohlokoa haholo bakeng sa mesebetsi ea ho sila le ho bentša. Ho thatafala ha bona le ho tšoarella ha nako e telele ho ntlafatsa haholo ts'ebetso ea bona lits'ebetsong tsena.

Mechanical Manufacturing Adjustments

Ho lokisa le ho ntlafatsa: Bakeng sa phetoho kapa ntlafatso ea litekanyo le likhohlano tsa masoba a neng a le teng nakong ea tlhahiso ea mochini, Tungsten Carbide Rotary Burrs hangata ke lisebelisoa tsa ho qala.

Ntlafatso ea Sebaka sa ho Lahlela

Ho Hloekisa Castings: Ts'ebetsong ea ho lahlela, li-burrs tsena li bohlokoa bakeng sa ho tlosa lisebelisoa tse ling ho tsoa ho casting le ho ntlafatsa boleng ba tsona ba bokaholimo.

Tšebeliso ea bona e pharalletseng liindastering tse fapaneng, joalo ka ho etsa thepa, ho lokisa likoloi, ho etsa litšepe, le sebaka sa sefofane, e totobatsa ts'ebetso e phahameng ea Tungsten Carbide Rotary Burrs.

Molemo oa ho Tsamaea Tseleng

• Tshebeletso e Sebetsang hantle le e Tshepehang;

• Boleng bo botle;

• Litheko tsa Tlholisano;

• OEM, ODM, OBM;

• Mefuta e mengata e fapaneng

• Phatlalatso e potlakileng le e ka tšeptjoang

Litaba tsa Sephutheloana

1 x Mofuta oa G Arc Pointed Tree Tungsten Carbide Rotary Burr

1 x Nyeoe ea Tšireletso

● Na o hloka OEM, OBM, ODM kapa neutral packing bakeng sa lihlahisoa tsa hau?

● Lebitso la khamphani ea hau le lintlha tsa khokahanyo bakeng sa maikutlo a potlakileng le a nepahetseng.

Ho feta moo, re u mema hore u kope mehlala ea tlhahlobo ea boleng.