Imisebenzi

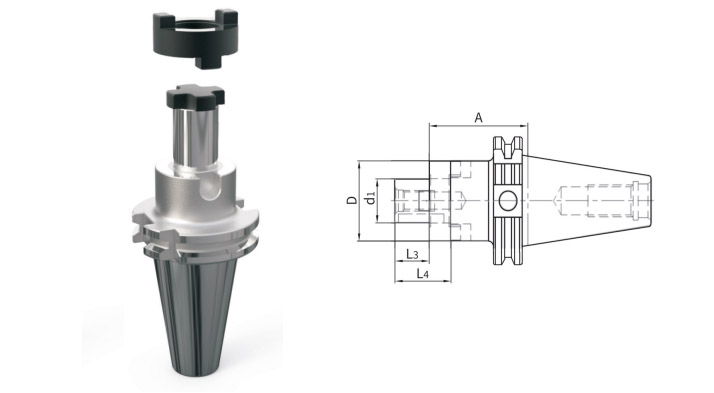

UkuQhotywa kweZixhobo okuZinzile:

Imodeli ye-JT yokudibanisa i-adaptha yobuso besixhobo sobuso be-adaptha yesibambi, kunye noyilo olukhethekileyo lwe-groove, inokubambelela ngokuqinileyo izisiki zokusila ngeegrooves ezinde okanye ezinqamlezayo. Oku kuqinisekisa ukuba isixhobo sihlala sizinzile ngexesha lokusikwa kwesantya esiphezulu, ukuthintela ukukhulula isixhobo okanye ukufuduswa, ngaloo ndlela kuphuculwe ukuchaneka komatshini kunye nomgangatho womphezulu.

UFaneka loLungiselelo olongezelelweyo:

Lo mphathi wesixhobo uxhasa utshintsho olukhawulezayo lwesixhobo, ukunciphisa amaxesha okutshintsha isixhobo kunye nexesha lokunciphisa umatshini, ukuphucula kakhulu ukusebenza kakuhle kokusebenza.

UkuNcitshiswa kweVibration kunye nobushushu:

I-clamping ezinzileyo inciphisa ukungcangcazela kwesixhobo ngexesha lomatshini kwaye inciphisa ubushushu obuveliswa ngexesha lokusika. Oku kunceda ukwandisa ubomi besixhobo kunye nokugcina umgangatho omhle womphezulu.

Ukuziqhelanisa neZixhobo ezahlukeneyo:

Umphathi wesixhobo se-JT wemodeli uyahambelana neendidi ezahlukeneyo zabasiki bokungqusha, ngakumbi abo banemiqolo emide okanye enqamlezayo, njengeemill zokuphela kweqokobhe kunyeiisarha zokusarha. Oku kuyenza isebenziseke kakhulu kwimisebenzi entsonkothileyo yomatshini.

Indlela yokusebenzisa

Ukuhlohla uMphathi weSixhobo:

Nyusa imodeli ye-JT yendibaniselwano yobuso besixhobo seadaptha yobuso kwisixhobo sokusonta somatshini wokungqusha. Qinisekisa uxhulumaniso oluqinileyo phakathi komphathi wesixhobo kunye ne-spindle ukuphepha ukungazinzi.

Ukubamba iMilling Cutter:

1. Khetha isixhobo sokusila esifanelekileyo esinegrooves emide okanye enqamlezayo, efana neqokobhe lokusila okanyeisarha yokucanda.

2. Faka i-shank ye-milling cutter kumngxuma wokubamba isixhobo se-JT, uqinisekise ukuba iigrooves ziyahambelana.

3. Sebenzisa isixhobo sokutshixa somphathi wesixhobo (umzekelo, izikrufu okanye amandongomane) ukuze uqinise ngokukhuselekileyo umsiki wokusila.

Ukulungelelanisa indawo yesixhobo:

Lungisa ubude bokwandiswa kunye ne-angle yesixhobo ngokweemfuno ze-machining zokuqinisekisa indawo efanelekileyo yokusika.

Ukuqala koMatshini:

Emva kokuqinisekisa ukuba isixhobo sifakwe ngokukhuselekileyo, qalisa umatshini wokugaya ukuqalisa inkqubo yomatshini. Umnini wesixhobo uya kunika inkxaso ezinzileyo ukuze kuqinisekiswe iziphumo zokusika ezichanekileyo.

Ukusetyenziswa koLumkelo

Qinisekisa ukuMatanisa iGroove:

Xa ucinezela i-cutter yokugaya, qiniseka ukuba i-grooves yesixhobo ihambelana ne-grooves kwisibambi sesixhobo se-JT. Iigrooves ezingahambelaniyo zinokukhokelela ekubambeni okungazinzanga, okuchaphazela ukuchaneka koomatshini kunye nokwandisa umngcipheko wokhuseleko.

Ukuhlolwa rhoqo koMphathi weSixhobo kunye noMqathango weSixhobo:

Ngaphambi nasemva kokusetyenziswa, jonga isibambi sesixhobo kunye nesisiki sokusika ukuba kukho nakuphi na ukunxiba okanye umonakalo. Ukuba imiba ifunyenwe, yitshintshe okanye uyilungise ngokukhawuleza ukuze uqinisekise ukuthembeka kwenkqubo yokudibanisa.

Kuphephe Ukusetyenziswa Okugqithisileyo:

Landela uluhlu lomthwalo olinganisiweyo womphathi wesixhobo kunye nesixhobo ukuphepha ukusisebenzisa phantsi kweemeko zomthwalo ophezulu. Ukulayisha ngaphezulu kunokubangela ukuguqulwa komphathi wesixhobo okanye umonakalo kwisixhobo, kuchaphazela umgangatho womatshini kunye nobomi besixhobo.

Gcina ucoceko:

Emva kokusetyenziswa ngalunye, coca isibambi sesixhobo kunye nezixhobo zokususa iichips kunye ne-debris. Ukugcina i-clamping surfaces icocekile inceda ukugcina ukusebenza kakuhle kwe-clamping kunye nokuthintela ukungazinzi ngenxa yokuqokelela ukungcola.

Ukusebenza ngendlela eyiyo kweNdlela yokuTyaxa:

Xa utshixa isixhobo, sebenzisa nkqu uxinzelelo ukuze ugweme ukuqiniswa kakhulu okanye ukuqina ngaphantsi kwelinye icala. Qinisekisa ukuba isixhobo asishukumi okanye asishukumi ngexesha lenkqubo yomatshini.

ULondolozo lwarhoqo:

Yenza ukugcinwa rhoqo kumphathi wesixhobo se-JT, kubandakanywa nokujonga izinto ezizibophezelayo ze-clamping mechanism ye-looseness, kunye ne-lubricating izingxenye ezihambayo ukuzigcina zikwimeko efanelekileyo yokusebenza. Oku kuqinisekisa ukuba umnini wesixhobo uhlala ekwimeko efanelekileyo yokusebenza.