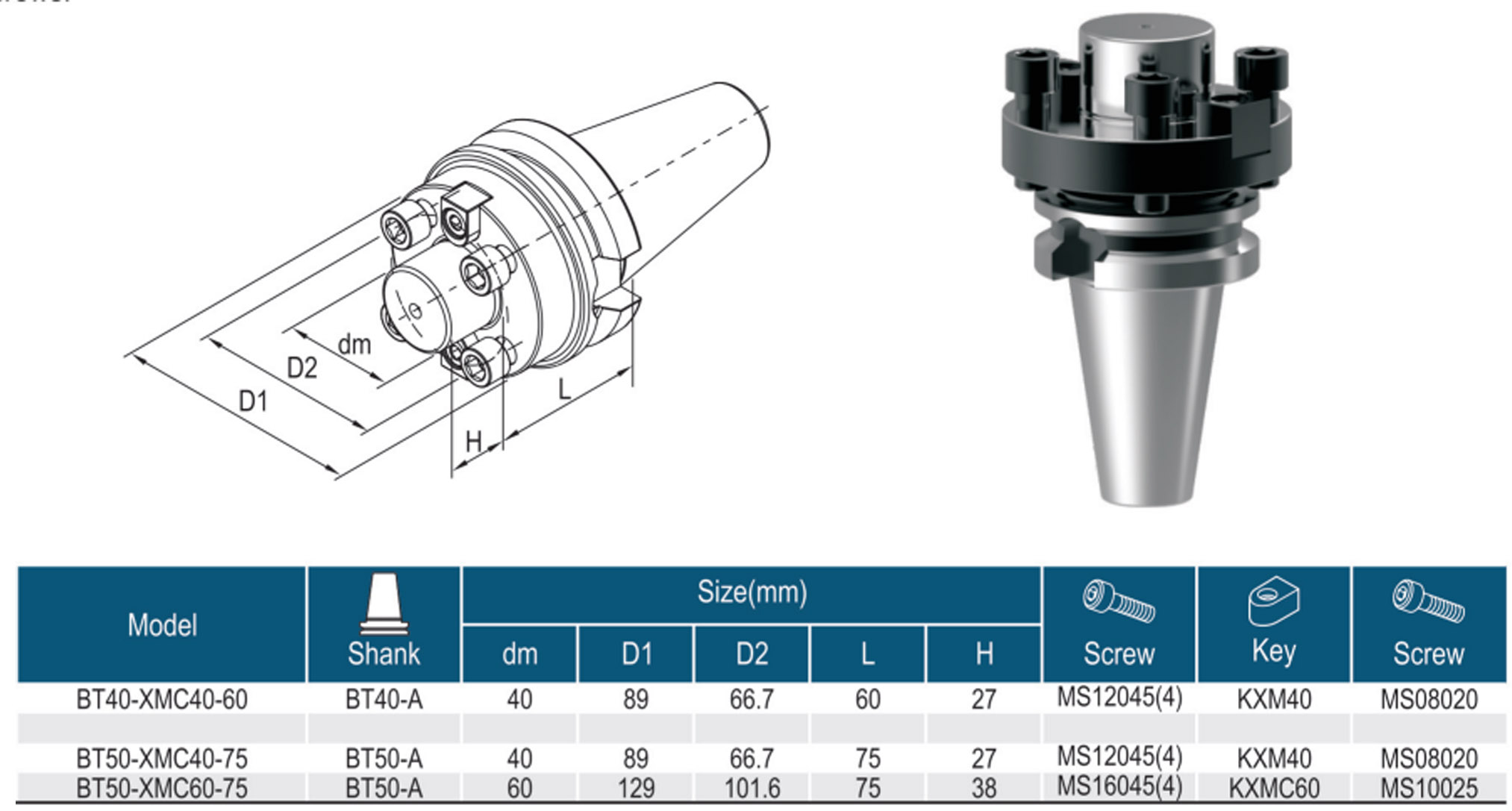

Isibambi sokusika ubuso sisixhobo esikhethekileyo esenzelwe ukugoba abasiki bobuso abanemingxuma emine. Isici sayo esiphambili kukunyuka koqhagamshelwano lwekhola, ebonelela ngokuzinza okukhulu ngexesha lomatshini we-high-speed machining. Isibambi siqhele ukubonelelwa ngezikrufu zokutshixa ukuqinisekisa ukuba umsiki ubotshelelwe ngokukhuselekileyo, ukuthintela ukukhulula okanye ukushukuma ngexesha lokusetyenziswa. Ubungakanani obuqhelekileyo be-shank bubandakanya i-BT40 kunye ne-BT50, ilungele oomatshini abahlukeneyo be-CNC kunye neemfuno zomatshini.

Umsebenzi

Umsebenzi ophambili wobusoisibambi sokusikakukuqinisa ngokukhuselekileyo i-face milling cutter kwi-spindle yomatshini ngokuchaneka okuphezulu, okwenza imisebenzi yokusika esebenzayo nechanekileyo. Izisiki zokusila zobuso zisetyenziswa ikakhulu ukwenza umphezulu wezixhobo zokusebenza, ezinoluhlu olubanzi lwezicelo kubuchwephesha oburhabaxa nokugqiba izinto ezifana nentsimbi, intsimbi ekhandiweyo, kunye nealloyi zealuminium. Ukuzinza komnini kuchaphazela ngokuthe ngqo ukugudisa kunye nomgangatho wenkqubo yokugaya. I-collar contact surface eyandisiweyo inika inkxaso enkulu, inciphisa ukungcangcazela kwesixhobo, iphucula ukuchaneka kokusika, kwaye yandisa ubomi benkonzo yesixhobo.

Imiyalelo yokusebenzisa

Ukuseta isixhobo: Lungelelanisa imingxuma emine yokukhwela yobuso bokusika kunye nemingxuma yesikrufu sokutshixa kwisibambi, uqinisekise ukuba umsiki ubekwe kakuhle. Sebenzisa izikrufu zokutshixa ezibonelelweyo ukuqinisa i-cutter, uziqinise kwi-torque efanelekileyo ukuthintela ukukhulula ngexesha lokusebenza.

Ukufakela uMbambi: Kuxhomekeke kubungakanani obufunekayo beshank (BT40 okanye BT50), faka isibambi kwi-spindle yomatshini we-CNC. Qinisekisa ukuba intambo yokusonta kunye nesibambi ziqhagamshelwe ngokuqinileyo, kwaye sebenzisa iqhosha lokutsala ukukhusela isibambi ngokuqinileyo.

Imisebenzi yoMatshini: Qalisa umatshini kwaye wenze uvavanyo lokusika ukujonga ukuzinza kwesixhobo kunye nomgangatho womphezulu womsebenzi. Ukuba ukusika kugudileyo kwaye ukugqitywa komphezulu kuhambelana neemfuno, qhubela phambili kunye ne-machining epheleleyo.

Ukusetyenziswa koLumkelo

Ukusetyenziswa kwezikrufu zokutshixa: Qinisekisa ukuba izikrufu zokutshixa ziqiniswe ngokulinganayo xa ufaka ubusoumsiki wokugayaukuthintela ukungahambi kakuhle, okunokubangela ukungazinzi ngexesha lokusebenza. Nika ingqalelo kwi-torque yokuqinisa ukuphepha ukugqithisa okanye ukunyanzeliswa, okunokuchaphazela ukusebenza kwesixhobo.

Coca iKhola yoQhagamshelwano loMmandla: I-collar contact surface iyona nkxaso ephambili phakathi komnini kunye nesixhobo. Ngaphambi kokusetyenziswa, qiniseka ukuba le ndawo icocekile kwaye ayinayo inkunkuma. Nayiphi na imathiriyeli yangaphandle inokuphazamisa amandla okubamba, okukhokelela ekungcangcazeleni okanye ukutyibilika ngexesha lokusika.

Ukulingana phakathi koMphathi kunye ne-Spindle: Xa ufaka isibambi kwi-spindle yomatshini, qinisekisa ukuba iindawo zokukhwelana zicocekile kwaye zigudile. Hlola rhoqo i-taper yomnini ukuqinisekisa ukuba ayonakaliswa okanye ayinxibanga. Ukuba i-taper yonakalisiwe, yitshintshe okanye uyilungise ngokukhawuleza ukugcina ukuchaneka komatshini.

Indawo yokusebenza: Kuphephe ukusebenzisa isibambi kwiimeko ezigqithisileyo, ezifana nobushushu obuphezulu okanye iimeko zokufuma, ezinokubangela ukuguqulwa kwezinto okanye ukurusa, okuchaphazela ubomi benkonzo kunye nokuchaneka komatshini.

ULondolozo lwarhoqo: Umnini sisixhobo esichanekileyo esifuna ukucocwa rhoqo kunye nokuhlolwa emva kokusetyenziswa, ngokukodwa ukujonga imeko ye-screws yokukhiya. Ukuba naziphi na izikrufu zibonisa iimpawu zokuguga okanye ukuguga, kufuneka zitshintshwe ngokukhawuleza.

Qhagamshelana: Jason Lee

I-imeyile: jason@wayleading.com

Ixesha lokuposa: Sep-30-2024