Precision 1-2-3, 2-3-4 or 2-4-6 Block With 1 And 11 And 23 Or None Hole

1-2-3, 2-3-4 Or 2-4-6 Block

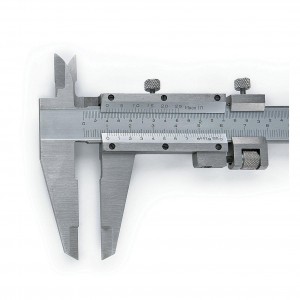

● Precision ground hardened.

● Tapped hole: 3/8"-16.

● Hardness: HRC55-62.

● 23, 11, 1, none hole are available.

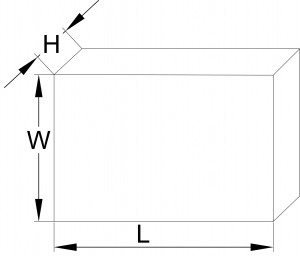

1-2-3"

| Size | Squareness | Tolerance Of Size | Hole | Order No. |

| 1x2x3" | 0.0003"/1" | ±0.0002" | 23 | 860-0024 |

| 0.0001"/1" | ±0.0003" | 23 | 860-0025 | |

| 0.0003"/1" | ±0.0002" | 11 | 860-0026 | |

| 0.0001"/1" | ±0.0003" | 11 | 860-0027 | |

| 0.0003"/1" | ±0.0002" | 1 | 860-0028 | |

| 0.0001"/1" | ±0.0003" | 1 | 860-0029 | |

| 0.0003"/1" | ±0.0002" | No Hole | 860-0030 | |

| 0.0001"/1" | ±0.0003" | No Hole | 860-0031 |

2-3-4"

| Size | Squareness | Parallel | Tolerance Of Size | Hole | Order No. |

| 2x3x4" | - | 0.0002" | ±0.0003" | 23 | 860-0967 |

| 0.0003"/1" | 0.0002" | ±0.0003" | 23 | 860-0968 |

2-4-6"

| Size | Squareness | Parallel | Tolerance Of Size | Hole | Order No. |

| 2x4x6" | 0.0003"/1" | 0.0002" | ±0.0005" | 23 | 860-0969 |

Metric Size

| Size | Squareness | Parallel | Tolerance Of Size | Hole | Order No. |

| 25x50x75mm | 0.0075mm | 0.005mm | ±0.0005" | 23 | 860-0970 |

| 25x50x75mm | 0.0075mm | 0.005mm | ±0.0005" | 23,M10 | 860-0971 |

| 25x50x100mm | 0.0075mm | 0.005mm | ±0.0005" | 23 | 860-0972 |

| 50x100x150mm | - | 0.005mm | ±0.0125" | 23 | 860-0973 |

Features and Importance in Precision Settings

Features and Importance in Precision Settings

1-2-3 blocks are a staple in the metalworking and machining industries, revered for their precision and versatility. These blocks, measuring exactly 1 inch by 2 inches by 3 inches, are typically crafted from hardened steel, a material choice that guarantees both durability and resistance to wear. This makes them an indispensable tool in settings where precision is paramount.

Variations and Specific Uses

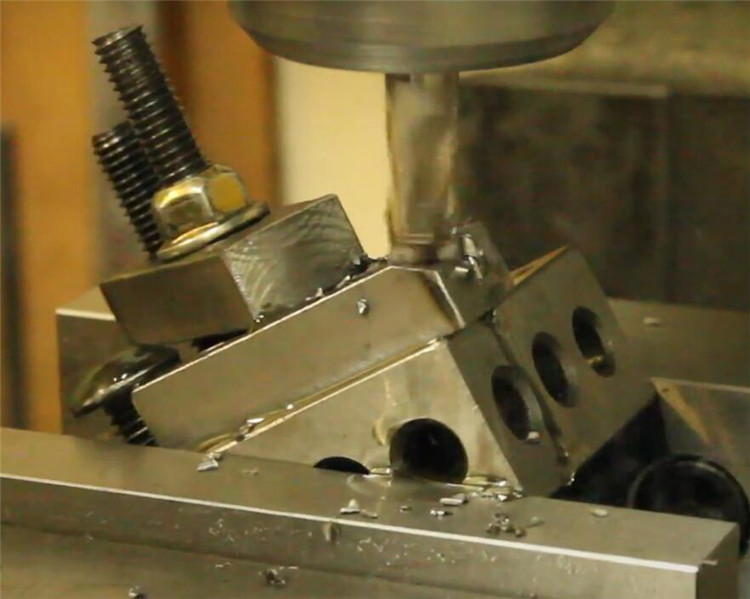

The range of 1-2-3 blocks includes several variations, distinguished mainly by the number and configuration of holes drilled into them. The most common types are the 23-hole, 11-hole, 1-hole, and the solid, no-hole block. Each type serves a unique purpose, catering to a variety of tasks in the workshop. The 23-hole and 11-hole blocks, for instance, are particularly useful for complex setups where multiple attachment points are needed. They allow for the attachment of clamps, bolts, and other fixtures, enabling the user to create a highly customized and secure setup for machining operations.

Applications in Inspection and Calibration

The 1-hole and no-hole blocks, on the other hand, are typically used for simpler tasks. The solid block, free of any perforations, offers a high degree of stability and is often used for supporting or spacing workpieces during inspection or layout tasks. The 1-hole block provides a minimalistic option when a single attachment point is sufficient.

Besides their primary function in setup and layout tasks, 1-2-3 blocks are also widely used in inspection and calibration. Their precise dimensions and right angles make them ideal for checking the accuracy of other tools and machines. Moreover, due to their simplicity and reliability, these blocks are a fundamental teaching tool in technical education, helping students understand the basics of machining and metalwork.

Significance in Metalworking Industry

1-2-3 blocks are a fundamental tool in the metalworking industry, known for their precision, versatility, and durability. They come in various configurations to suit a wide range of tasks, making them an essential component in any machining or metalworking setup.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x 1-2-3 blocks

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.