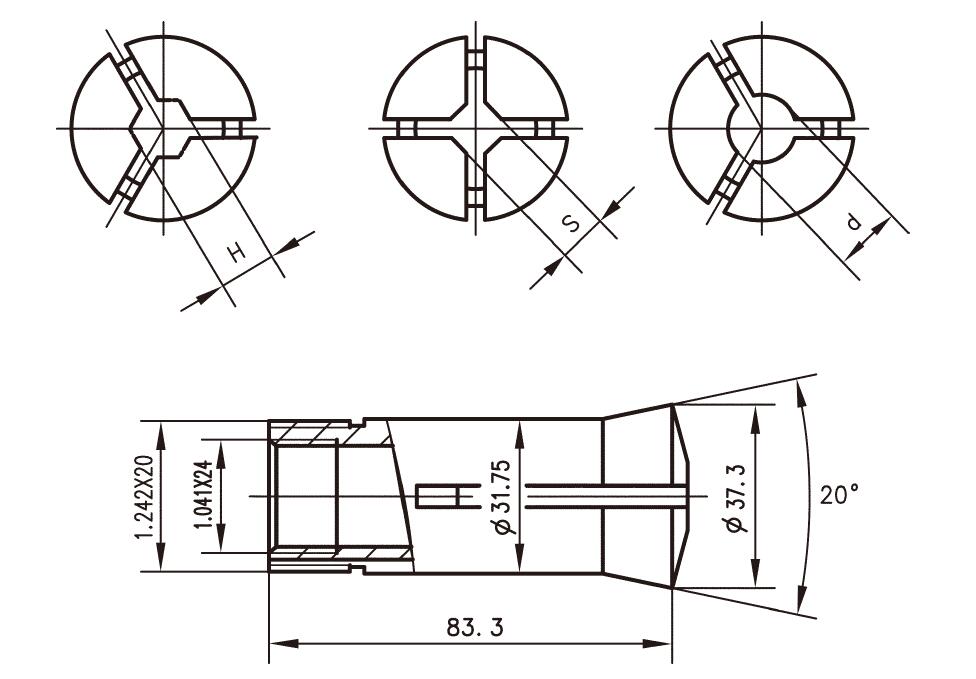

5C Hex Collet With Inch and Metric Size

5C Hex Collet

● Material: 65Mn

● Hardness: Clamping part HRC: 55-60, elastic part: HRC40-45

● This unit is applicable to all sorts of lathes, which spindle taper hole is 5C, such as automatic lathes, CNC lathes etc.

Metric

| Size | Economy | Premium .0005” T.I.R |

| 3mm | 660-8471 | 660-8494 |

| 4mm | 660-8472 | 660-8495 |

| 5mm | 660-8473 | 660-8496 |

| 6mm | 660-8474 | 660-8497 |

| 7mm | 660-8475 | 660-8498 |

| 8mm | 660-8476 | 660-8499 |

| 9mm | 660-8477 | 660-8500 |

| 10mm | 660-8478 | 660-8501 |

| 11mm | 660-8479 | 660-8502 |

| 12mm | 660-8480 | 660-8503 |

| 13mm | 660-8481 | 660-8504 |

| 13.5mm | 660-8482 | 660-8505 |

| 14mm | 660-8483 | 660-8506 |

| 15mm | 660-8484 | 660-8507 |

| 16mm | 660-8485 | 660-8508 |

| 17mm | 660-8486 | 660-8509 |

| 17.5mm | 660-8487 | 660-8510 |

| 18mm | 660-8488 | 660-8511 |

| 19mm | 660-8489 | 660-8512 |

| 20mm | 660-8490 | 660-8513 |

| 20.5mm | 660-8491 | 660-8514 |

| 21mm | 660-8492 | 660-8515 |

| 22mm | 660-8493 | 660-8516 |

Inch

| Size | Economy | Premium .0005” T.I.R |

| 1/8” | 660-8517 | 660-8542 |

| 5/32” | 660-8518 | 660-8543 |

| 3/16” | 660-8519 | 660-8544 |

| 7/32” | 660-8520 | 660-8545 |

| 1/4” | 660-8521 | 660-8546 |

| 9/32” | 660-8522 | 660-8547 |

| 5/16” | 660-8523 | 660-8548 |

| 11/32” | 660-8524 | 660-8549 |

| 3/8” | 660-8525 | 660-8550 |

| 13/32” | 660-8526 | 660-8551 |

| 7/16” | 660-8527 | 660-8552 |

| 15/32” | 660-8528 | 660-8553 |

| 1/2” | 660-8529 | 660-8554 |

| 17/32” | 660-8530 | 660-8555 |

| 9/16” | 660-8531 | 660-8556 |

| 19/32” | 660-8532 | 660-8557 |

| 5/8” | 660-8533 | 660-8558 |

| 21/32” | 660-8534 | 660-8559 |

| 11/16” | 660-8535 | 660-8560 |

| 23/32” | 660-8536 | 660-8561 |

| 3/4” | 660-8537 | 660-8562 |

| 25/32” | 660-8538 | 660-8563 |

| 13/16” | 660-8539 | 660-8564 |

| 27/32” | 660-8540 | 660-8565 |

| 7/8” | 660-8541 | 660-8566 |

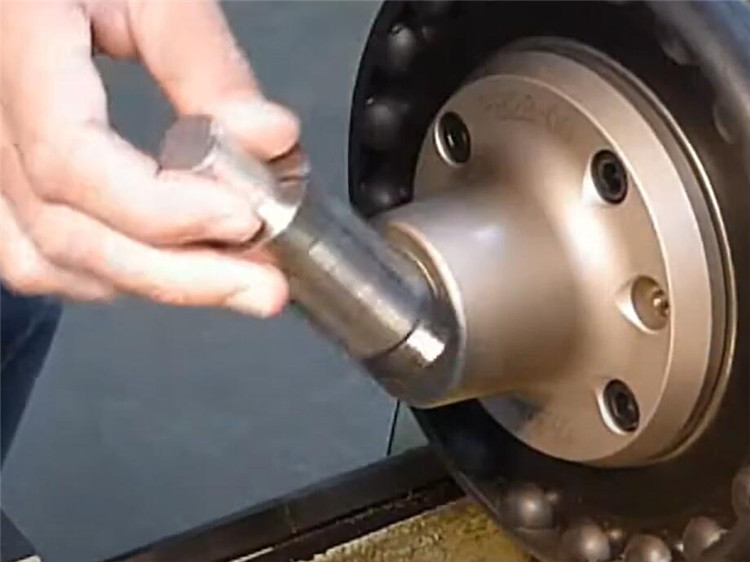

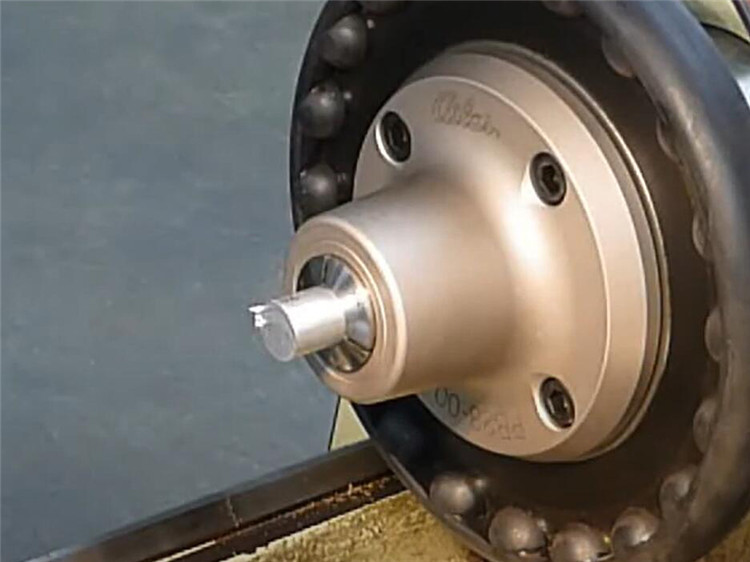

Hexagonal Machining Versatility

The 5C hex collet is an exceptionally versatile and crucial tooling component within the machining industry, celebrated for its precision and adaptability. It primarily serves to securely hold workpieces in lathes, milling machines, and grinding machines. While the 5C hex collet is adept at gripping cylindrical objects, its specialty lies in accommodating hexagonal shapes, broadening its application scope across various machining tasks.

High-Precision Manufacturing

In the realm of precision machining, where accuracy is of utmost importance, the 5C hex collet delivers the required stability and precision. This makes it a popular choice in the production of aerospace components, automotive parts, and complex medical devices, ensuring that these components conform to the rigorous tolerances demanded in such industries.

Tool and Die Making

The 5C hex collet also plays a pivotal role in tool and die making. The ability to precisely hold workpieces of diverse shapes and sizes, particularly hexagonal ones, is essential. The uniform clamping force of the 5C hex collet helps prevent workpiece distortion, crucial for preserving the integrity of the tool or die during machining.

Educational Machining Aid

In educational and training contexts, such as technical schools and universities, the 5C hex collet is a valuable teaching aid. It provides students with practical experience in using specialized tooling and deepens their understanding of precision machining techniques, particularly with hexagonal shapes.

Prototyping and Fabrication Efficiency

Moreover, the 5C hex collet is extensively utilized in custom fabrication and prototyping. Its capability for rapid tool changes facilitates swift transitions between different workpieces, thus reducing setup times and enhancing overall productivity.

The 5C hex collet is a key tool in the world of machining, with wide-ranging applications from high-precision manufacturing to educational environments. Its ability to handle hexagonal parts with precision and efficiency makes it an invaluable asset for various machining operations.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x 5C Hex collet

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.