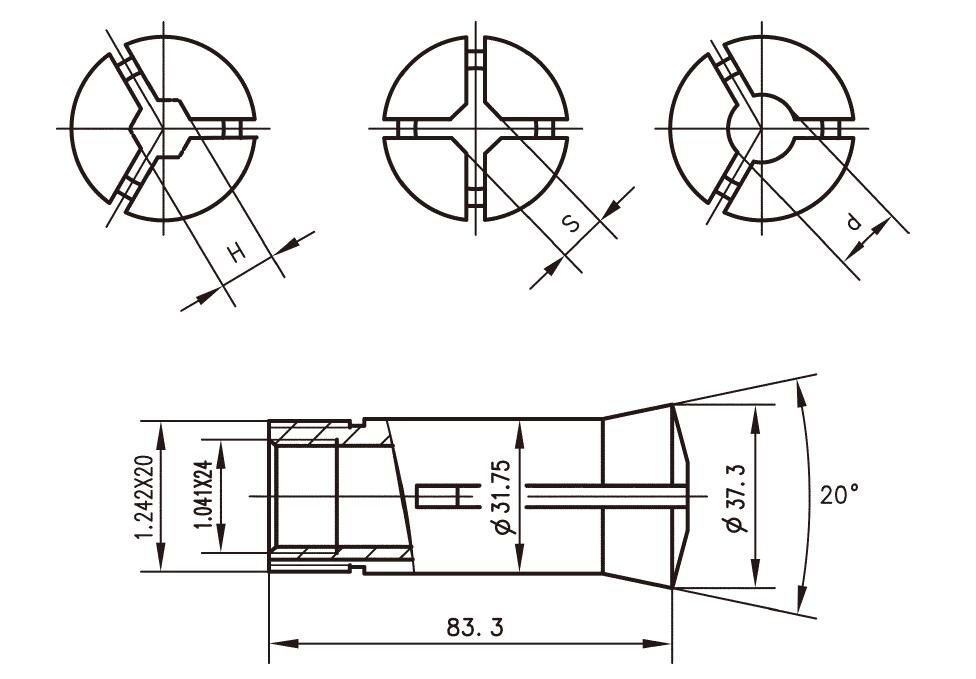

5C Square Collet With Inch and Metric Size

5C Square Collet

● Material: 65Mn

● Hardness: Clamping part HRC: 55-60, elastic part: HRC40-45

● This unit is applicable to all sorts of lathes, which spindle taper hole is 5C, such as automatic lathes, CNC lathes etc.

Metric

| Size | Economy | Premium .0005” T.I.R |

| 3mm | 660-8387 | 660-8408 |

| 4mm | 660-8388 | 660-8409 |

| 5mm | 660-8389 | 660-8410 |

| 5.5mm | 660-8390 | 660-8411 |

| 6mm | 660-8391 | 660-8412 |

| 7mm | 660-8392 | 660-8413 |

| 8mm | 660-8393 | 660-8414 |

| 9mm | 660-8394 | 660-8415 |

| 9.5mm | 660-8395 | 660-8416 |

| 10mm | 660-8396 | 660-8417 |

| 11mm | 660-8397 | 660-8418 |

| 12mm | 660-8398 | 660-8419 |

| 13mm | 660-8399 | 660-8420 |

| 13.5mm | 660-8400 | 660-8421 |

| 14mm | 660-8401 | 660-8422 |

| 15mm | 660-8402 | 660-8423 |

| 16mm | 660-8403 | 660-8424 |

| 17mm | 660-8404 | 660-8425 |

| 17.5mm | 660-8405 | 660-8426 |

| 18mm | 660-8406 | 660-8427 |

| 19mm | 660-8407 | 660-8428 |

Inch

| Size | Economy | Premium .0005” T.I.R |

| 1/8“ | 660-8429 | 660-8450 |

| 5/32” | 660-8430 | 660-8451 |

| 3/16” | 660-8431 | 660-8452 |

| 7/32” | 660-8432 | 660-8453 |

| 1/4” | 660-8433 | 660-8454 |

| 9/32” | 660-8434 | 660-8455 |

| 5/16” | 660-8435 | 660-8456 |

| 11/32” | 660-8436 | 660-8457 |

| 3/8” | 660-8437 | 660-8458 |

| 13/32” | 660-8438 | 660-8459 |

| 7/16” | 660-8439 | 660-8460 |

| 15/32” | 660-8440 | 660-8461 |

| 1/2” | 660-8441 | 660-8462 |

| 17/32” | 660-8442 | 660-8463 |

| 9/16” | 660-8443 | 660-8464 |

| 19/32” | 660-8444 | 660-8465 |

| 5/8” | 660-8445 | 660-8466 |

| 21/32” | 660-8446 | 660-8467 |

| 11/16” | 660-8447 | 660-8468 |

| 23/32” | 660-8448 | 660-8469 |

| 3/4” | 660-8449 | 660-8470 |

Versatility in Machining

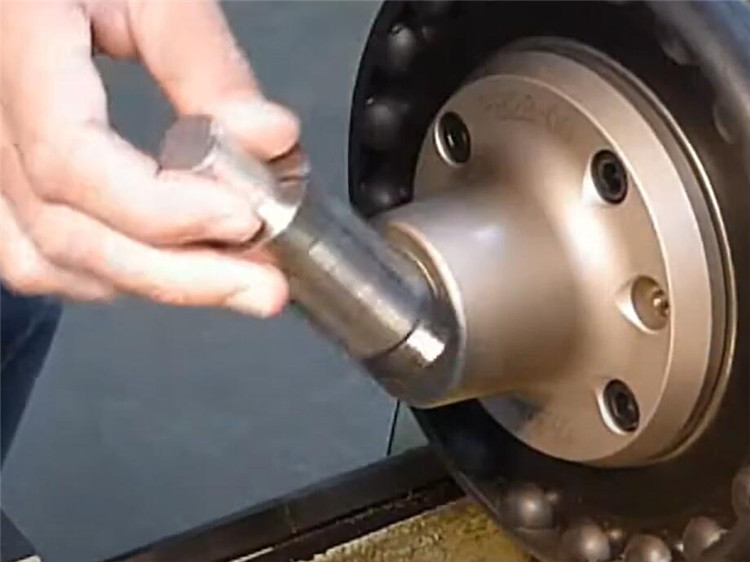

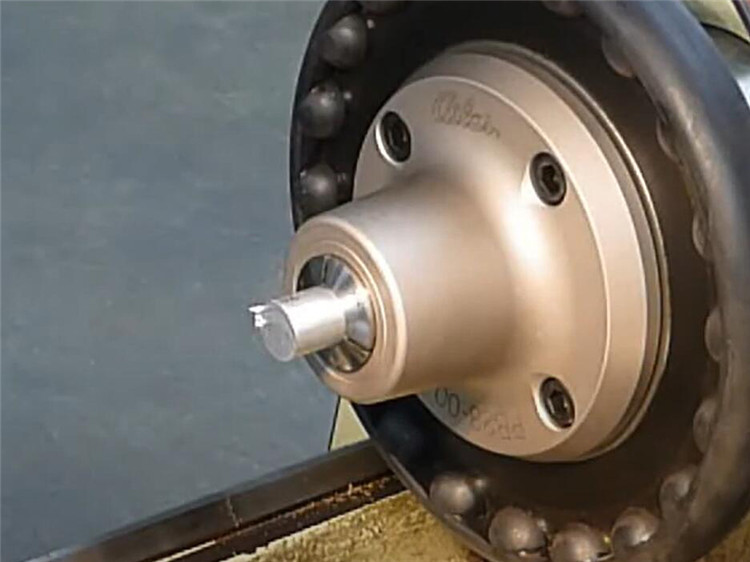

The 5C collet is a highly versatile and indispensable tooling component in the machining industry, renowned for its precision and adaptability. Its primary application lies in holding workpieces securely in lathes, milling machines, and grinding machines. The 5C collet excels in gripping cylindrical objects, but its range extends to holding hexagonal and square shapes, making it suitable for a wide variety of machining tasks.

Precision in Manufacturing

In precision machining, where accuracy is paramount, the 5C collet provides the necessary stability and exactness. It is widely used in the manufacture of aerospace components, automotive parts, and intricate medical devices. The precision of the 5C collet ensures that these components meet the stringent tolerances required in these industries.

Tool and Die Making Efficiency

Another significant application of the 5C collet is in tool and die making. Here, the collet’s ability to hold workpieces of different shapes and sizes with precision is crucial. Its uniform clamping force minimizes the risk of workpiece deformation, a vital factor in maintaining the integrity of the tool or die being machined.

Educational and Training Use

In the realm of education and training, the 5C collet is commonly used in technical schools and universities. It offers students hands-on experience with industrial-grade tooling and helps them understand the nuances of precision machining.

Custom Fabrication and Prototyping

Furthermore, the 5C collet is widely used in custom fabrication and prototyping. Its quick-change capability allows for efficient transitions between different workpieces, significantly reducing setup time and increasing overall productivity.

In summary, the 5C collet is a key player in the machining world, with applications spanning from high-precision manufacturing sectors to educational settings. Its versatility, precision, and efficiency make it a valuable tool for any machining operation.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x 5C square collet

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.