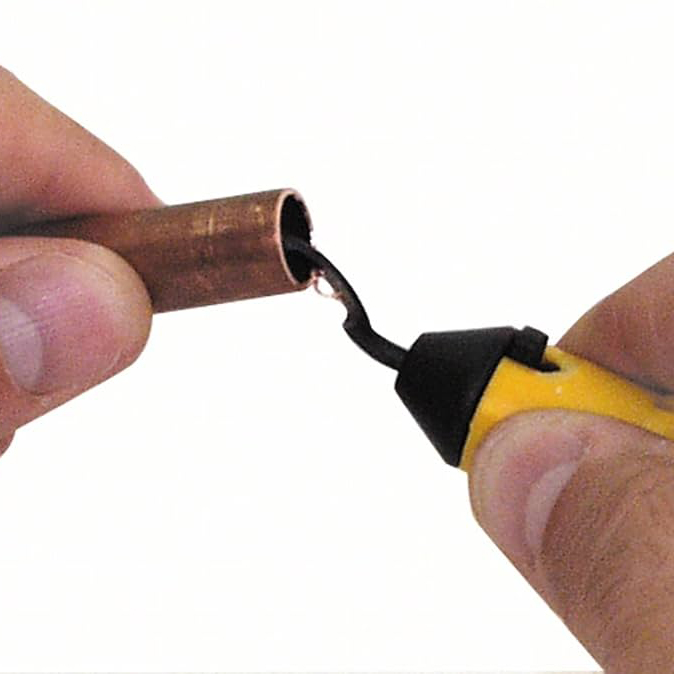

Deburring Tool Blades Using For Deburring

Deburring Tool Blades

● E Type Is Heavy duty type, B type is light duty type.

● Incl. angle degree: E100 for 40°, E200 for 60°, E300 for 40°, B10 for 40°, B20 for 80°.

● Material: HSS

● Hardness: HRC62-64

● E type Blades dia: 3.2mm, B type blades dia: 2.6mm

| Model | Type | Order No. |

| E100 | 10pcs/Set, Heay Duty Type | 660-8760 |

| E200 | 10pcs/Set, Heay Duty Type | 660-8761 |

| E300 | 10pcs/Set, Heay Duty Type | 660-8762 |

| B10 | 10pcs/Set, Light Duty Type | 660-8763 |

| B20 | 10pcs/Set, Light Duty Type | 660-8764 |

Application

Deburring Tool Blades are specialized tools designed for removing burrs from metal or plastic parts. These burrs often occur during manufacturing processes like cutting, milling, or drilling. Made of High-Speed Steel (HSS), Deburring Tool Blades are widely appreciated in industrial applications for their durability and efficiency. Among the HSS series, the models E100, E200, E300, B10, and B20 are prevalent, with the E series representing heavy-duty blades and the B series representing light-duty blades.

When selecting Deburring Tool Blades, considering the model and material of the blade is crucial. HSS blades offer excellent wear resistance and hardness, making them an ideal choice for handling a variety of materials. Whether it’s the heavy-duty E series or the light-duty B series, users can choose the appropriate blade based on their specific application needs. These tools not only enhance processing efficiency but also ensure product quality and safety, making them an indispensable part of modern manufacturing. With technological advancements, the application of these blades in various industrial fields is expected to continue expanding.

About E100, E200, and E300

The E100, E200, and E300 models of Deburring Tool Blades are designed for heavy-duty deburring tasks. They are typically used for removing burrs from larger or rougher metal parts, such as in automotive manufacturing, heavy machinery, and aerospace industries. These heavy-duty blades are favored in industrial settings for their durability and ability to withstand high pressures. For instance, the E100 model is particularly suited for deburring large iron or steel parts, while the E200 and E300 models are more applicable for materials of varying hardness and thickness.

About B10 and B20

For lighter applications, the B10 and B20 models of Deburring Tool Blades excel. These blades are often used in precision engineering, such as in the manufacturing of electronic components, processing of plastic products, and finishing of small metal parts. Their design focuses on precise and meticulous deburring to prevent unnecessary damage to the material. The B10 model is especially suitable for small and thin-walled components, whereas the B20 is applicable for slightly more complex or harder materials.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

10 x Deburring Tool Blades

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.