Digital Depth Gauge With Stainless Steel For Industrial Type

Digital Depth Gauge

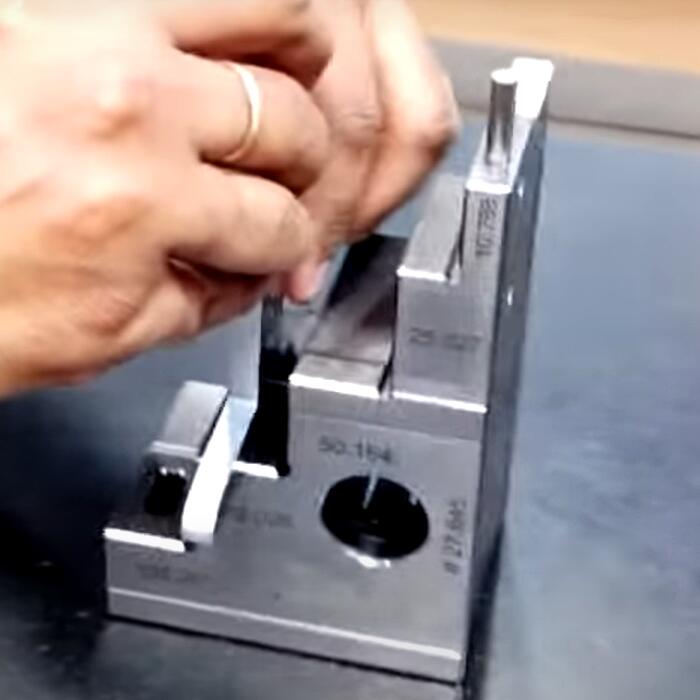

● Designed for measuring depth of holes, slots and recesses.

● Satin chrome plated reading surface.

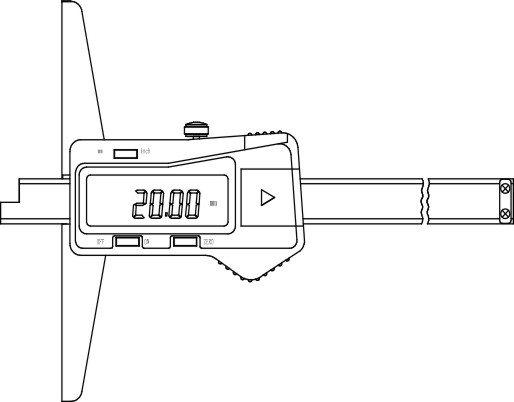

Without Hook

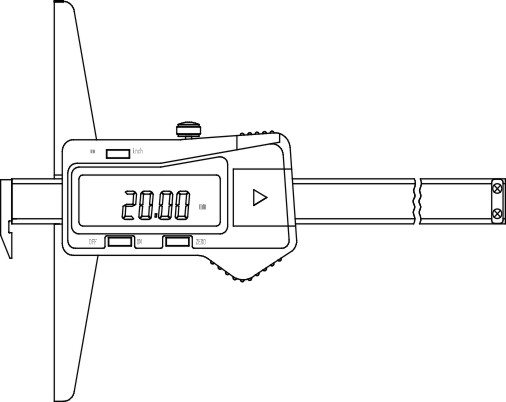

With Hook

| Measuring Range | Graduation | Without Hook | With Hook |

| Order No. | Order No. | ||

| 0-150mm/6" | 0.01mm/0.0005" | 860-0946 | 860-0952 |

| 0-200mm/8" | 0.01mm/0.0005" | 860-0947 | 860-0953 |

| 0-300mm/12" | 0.01mm/0.0005" | 860-0948 | 860-0954 |

| 0-500mm/20" | 0.01mm/0.0005" | 860-0949 | 860-0955 |

| 0-150mm/24" | 0.01mm/0.0005" | 860-0950 | 860-0956 |

| 0-200mm/40" | 0.01mm/0.0005" | 860-0951 | 860-0957 |

Digital Precision for Depth Measurement

A digital depth gauge represents a cutting-edge advancement in precision instruments, specifically tailored for accurately measuring the depth of holes, slots, and recesses in engineering and manufacturing applications. This sophisticated tool, equipped with digital technology, enhances depth measurements with efficiency and precision.

Primary Application in Mechanical Engineering

Mechanical engineering and machining demand meticulous precision, especially when creating components that must seamlessly fit together, as seen in automotive or aerospace engineering. The digital depth gauge takes center stage in this context, allowing engineers to measure depths with exceptional accuracy. The digital interface provides quick and clear readings, ensuring components meet stringent specifications. The ability to toggle between metric and imperial units further adds to the versatility of the digital depth gauge, accommodating various measurement systems prevalent in different industries. This adaptability ensures its widespread use and relevance across diverse engineering applications.

Critical Role in Quality Control

Quality control is paramount in the manufacturing industry, particularly in mass production scenarios. Ensuring that every part meets specified dimensions is crucial for the functionality and safety of the final product. The digital depth gauge emerges as a key player in routine checks of feature depths in manufactured parts, contributing to maintaining consistency and high-quality standards across production runs. Additionally, the digital depth gauge often comes equipped with features like data logging and wireless connectivity. These features enable seamless integration with quality control processes, allowing for efficient data management and analysis. This connectivity is especially beneficial in Industry 4.0 environments where digitalization and automation play a central role in manufacturing processes.

Versatile Applications in Scientific Research

Beyond manufacturing, the digital depth gauge finds valuable applications in scientific research and development. In fields like materials science and physics, where researchers often need to measure the depth of microscopic features on materials or experimental apparatus, the precision and efficiency of the digital depth gauge make it an indispensable tool. It facilitates accurate data collection and analysis, supporting advancements in scientific understanding. The digital depth gauge’s ability to capture and store measurements digitally enhances reproducibility in experiments. Researchers can easily track and share precise depth measurements, contributing to the robustness of scientific studies and fostering collaboration among research teams.

Digital Depth Gauge: A Versatile Precision Tool

The digital depth gauge stands as a versatile and essential tool across various industries requiring precise depth measurements. Its applications span from engineering and manufacturing to quality control and scientific research. The incorporation of digital technology elevates its functionality, providing a user-friendly interface and efficient depth measurements. As industries continue to demand higher precision and efficiency, the digital depth gauge, often referred to as a depth caliper, remains at the forefront of ensuring accurate and reliable depth-related measurements. Its adaptability, connectivity features, and contribution to both industrial and scientific advancements solidify its status as an indispensable tool in the realm of precision measurement.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Digital Depth Gauge

1 x Protective Case

1 x Test Report By Our Factory

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.