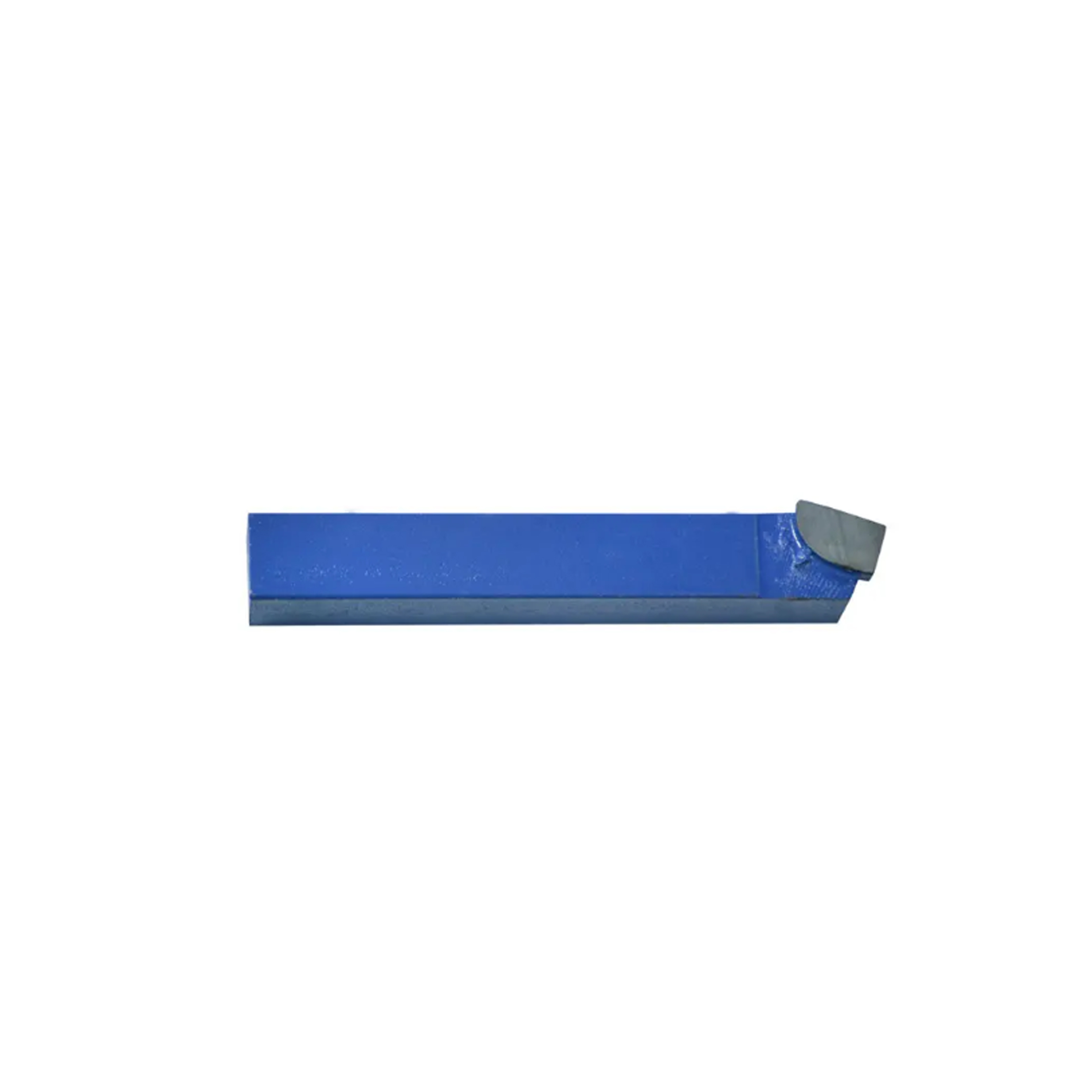

DIN4971-ISO1 Carbide Tipped Tool Bit With Right And Left Hand

DIN4971-ISO1 Carbide Tipped Tool Bit

We are pleased that you are interested in our carbide tipped tool bit. The DIN4971-ISO1 Carbide Tipped Tool Bit is a high-performance tool for precision machining, ideal for cutting steel, stainless steel, cast iron, and non-ferrous metals.

| SIZE MM |

GRADE K10 | GRADE P25 | ||||

| LEFT HAND | RIGHT HAND | LEFT HAND | RIGHT HAND | |||

| 10×10×90 | 660-6950 | 660-6956 | 660-6962 | 660-6968 | ||

| 12×12×100 | 660-6951 | 660-6957 | 660-6963 | 660-6969 | ||

| 16×16×110 | 660-6952 | 660-6958 | 660-6964 | 660-6970 | ||

| 20×20×125 | 660-6953 | 660-6959 | 660-6965 | 660-6971 | ||

| 25×25×140 | 660-6954 | 660-6960 | 660-6966 | 660-6972 | ||

| 32×32×170 | 660-6955 | 660-6961 | 660-6967 | 660-6973 | ||

Application

Functions For Carbide Tipped Tool Bit:

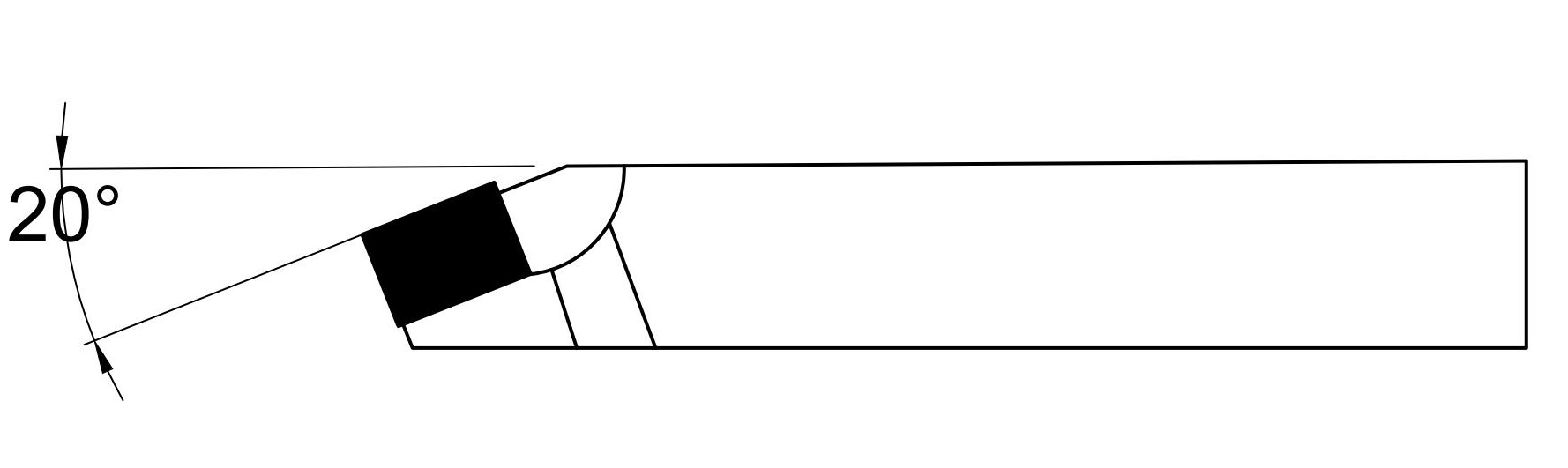

This tool bit is primarily used for turning, facing, and chamfering operations on lathes. Its carbide tip ensures superior cutting performance, longer tool life, and improved surface finish on the workpiece. The tool bit conforms to DIN 4971 and ISO 1 standards, ensuring compatibility and high quality.

Usage For Carbide Tipped Tool Bit:

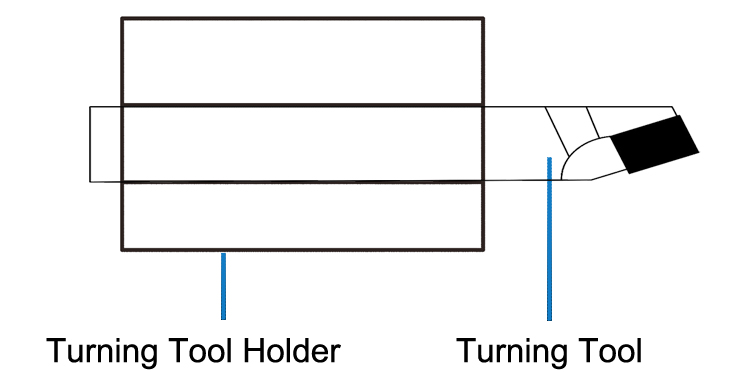

1. Tool Bit Installation: Secure the tool bit in the tool holder of the lathe. Ensure it is properly aligned and clamped tightly to prevent movement during operation.

2. Setting Up the Lathe: Adjust the lathe settings, including spindle speed, feed rate, and depth of cut, based on the material being machined and the desired finish.

3. Machining Operation: Start the lathe and carefully engage the tool bit with the workpiece. Perform the required turning, facing, or chamfering operations, ensuring smooth and steady movements.

4. Monitoring and Adjustment: Continuously monitor the machining process, making necessary adjustments to parameters to maintain optimal cutting conditions and achieve the desired results.

Precautions For Carbide Tipped Tool Bit:

1. Proper Tool Selection: Choose the appropriate tool bit size and geometry based on the specific machining task and material properties.

2. Secure Clamping: Ensure the tool bit is securely clamped in the tool holder to prevent vibration and tool movement during cutting, which could lead to poor surface finish or tool breakage.

3. Optimal Cutting Parameters: Set appropriate cutting parameters (speed, feed, depth of cut) to avoid excessive tool wear, overheating, and potential tool failure.

4. Personal Protective Equipment (PPE): Always wear suitable PPE, such as safety glasses and gloves, to protect against flying chips and sharp edges.

5. Regular Inspection: Regularly inspect the carbide tip for signs of wear or damage. Replace the tool bit if necessary to maintain cutting performance and workpiece quality.

6. Coolant Usage: Use appropriate coolant or lubrication to reduce cutting temperature and extend the tool life, especially when machining hard or abrasive materials.

7. Safe Operation: Ensure the lathe is operated according to the manufacturer's instructions and safety guidelines to prevent accidents and injuries.

Advantage

Efficient and Reliable Service

Wayleading Tools, your one-stop supplier for cutting tools, machinery accessories, measuring tools. As an integrated industrial powerhouse, we take immense pride in our Efficient and Reliable Service, tailored to meet the diverse needs of our esteemed clientele. Click Here For More

Good Quality

At Wayleading Tools, our commitment to Good Quality sets us apart as a formidable force in the industry. As an integrated powerhouse, we offer a diverse range of cutting-edge industrial solutions, providing you with the finest cutting tools, precise measuring instruments, and reliable machine tool accessories.Click Here For More

Competitive Pricing

Welcome to Wayleading Tools, your one-stop supplier for cutting tools, measuring tools, machinery accessories. We take immense pride in offering Competitive Pricing as one of our core advantages. Click Here For More

OEM, ODM, OBM

At Wayleading Tools, we take pride in offering comprehensive OEM (Original Equipment Manufacturer), ODM (Original Design Manufacturer), and OBM (Own Brand Manufacturer) services, catering to your unique needs and ideas.Click Here For More

Extensive Variety

Welcome to Wayleading Tools, your all-in-one destination for cutting-edge industrial solutions, where we specialize in cutting tools, measuring instruments, and machine tool accessories. Our core advantage lies in offering an Extensive Variety of products, tailored to meet the diverse needs of our esteemed clientele.Click Here For More

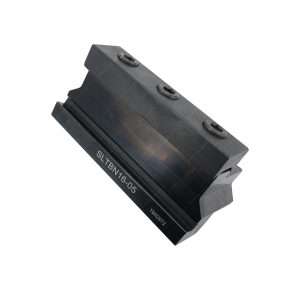

Matching Items

Matched holder:Quick Change Tool Post And Holder

Solution

Technical Support:

We are delighted to be your solution provider for ER collet. We are happy to offer you technical support. Whether it's during your sales process or your customers' usage, upon receiving your technical inquiries, we will promptly address your questions. We promise to reply within 24 hours at the latest, providing you with technical solutions.Click Here For More

Customized Services:

We are pleased to offer you customized services for ER collet. We can provide OEM services, manufacturing products according to your drawings; OBM services, branding our products with your logo; and ODM services, adapting our products according to your design requirements. Whatever customized service you require, we promise to provide you with professional customization solutions.Click Here For More

Training Services:

Whether you are the purchaser of our products or an end-user, we are more than happy to provide training service to ensure you use the products you purchased from us correctly. Our training materials come in electronic documents, videos, and online meetings, allowing you to choose the most convenient option. From your request for training to our provision of training solutions, we promise to complete the entire process within 3 days Click Here For More

After-sales Service:

Our products come with a 6-month after-sales service period. During this period, any problems not intentionally caused will be replaced or repaired free of charge. We provide round-the-clock customer service support, handling any usage queries or complaints, ensuring you have a pleasant purchasing experience. Click Here For More

Solution Design:

By providing your machining product blueprints (or assisting in creating 3D drawings if unavailable), material specifications, and mechanical details used, our product team will tailor the most suitable recommendations for cutting tools, mechanical accessories, and measuring instruments, and design comprehensive machining solutions for you. Click Here For More

Packing

Packaged in a plastic box. Then packed in an outer box. It can be well protecting the carbide tipped tool bit. Also customized packing is welcomed.

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.