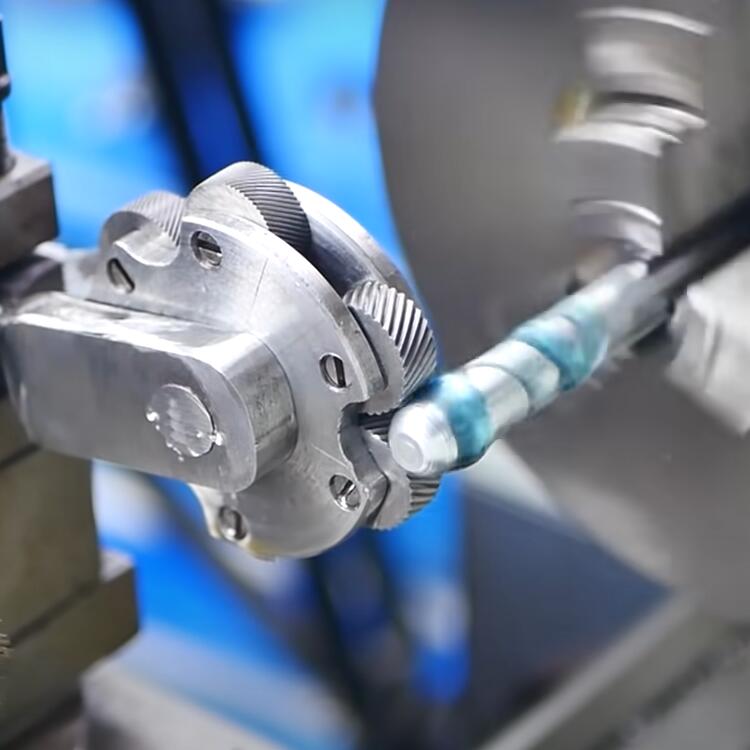

Dual Wheel Knurling Tools With Diamond Pattern For Industrial Type

Dual Wheel Knurling Tools

● Complete with medium cut HSS Or 9SiCr knurl best sutied for shorter work

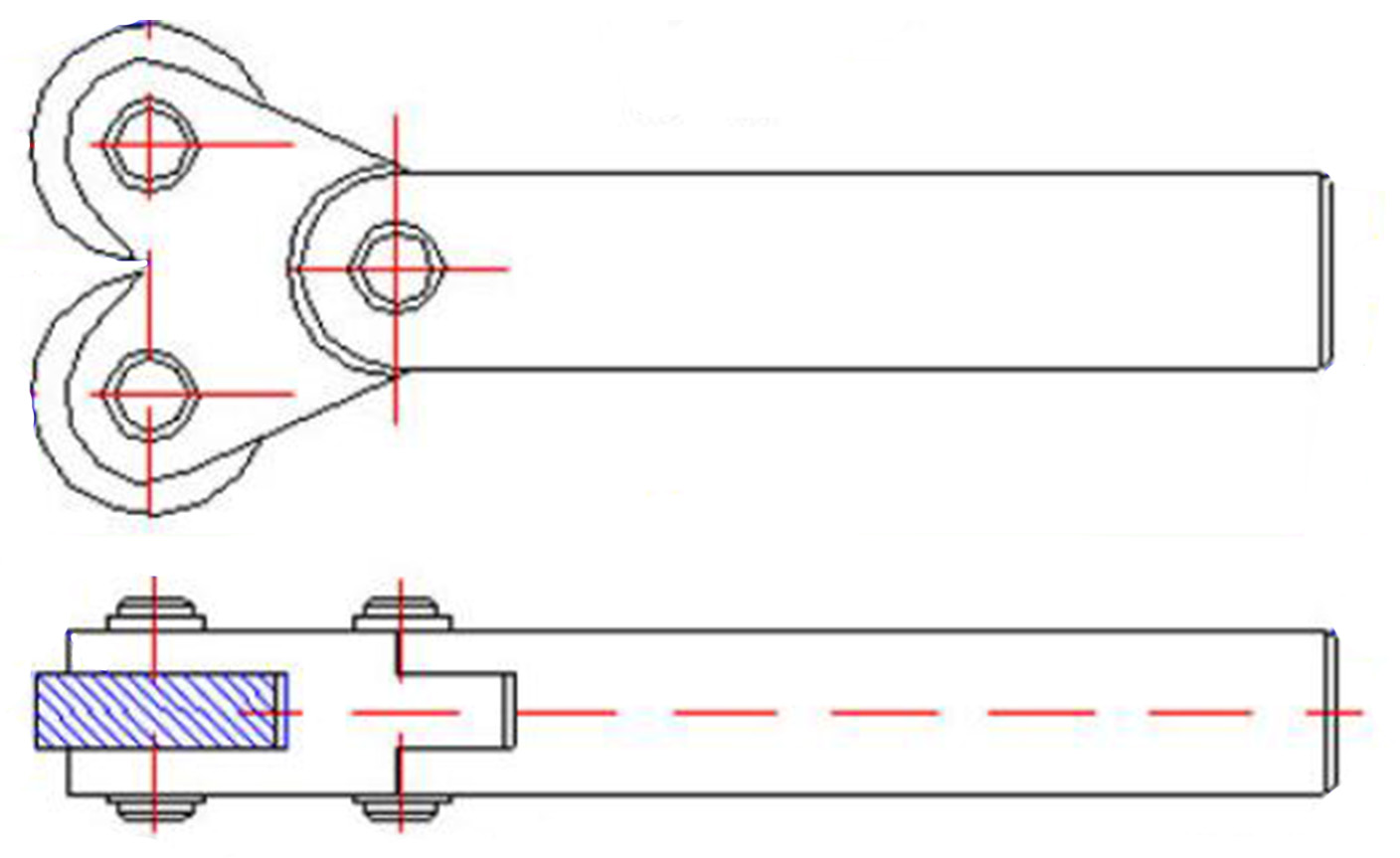

● Holder size: 21x18mm

● Pitch: From 0.4 to 2mm

● Length: 137mm

● Pitch: From 0.4 to 2mm

● Wheel Dia.: 26mm

● For Diamond Pattern

| Pitch | Alloy Steel | HSS |

| 0.4 | 660-7910 | 660-7919 |

| 0.5 | 660-7911 | 660-7920 |

| 0.6 | 660-7912 | 660-7921 |

| 0.8 | 660-7913 | 660-7922 |

| 1.0 | 660-7914 | 660-7923 |

| 1.2 | 660-7915 | 660-7924 |

| 1.6 | 660-7916 | 660-7925 |

| 1.8 | 660-7917 | 660-7926 |

| 2.0 | 660-7918 | 660-7927 |

Textured Design Application

Wheel knurling tools are indispensable in metal fabrication, primarily for applying unique textured designs on cylindrical metal surfaces. Their key role is to augment both the tactile feel and visual appeal of metal items.

Enhanced Grip for Handled Components

These tools perform knurling by pressing specific patterns onto metal rods’ smooth surfaces. The tool’s motion over the metal reshapes its surface, forming a uniform, raised pattern. This newly created texture considerably heightens the friction between the metal and the user’s hand. Such enhanced grip is vital for frequently handled items like tool handles, levers, and specially crafted metal parts needing manual adjustments.

Safety and Precision in Automotive and Aerospace

In sectors demanding safe and precise handling, like the automotive and aerospace industries, wheel knurling tools prove indispensable. For instance, in automotive manufacturing, they’re used to forge non-slip textures on gear levers and control knobs, ensuring a reliable grip even in slippery conditions. Similarly, in aerospace, these tools provide critical grip enhancements to cockpit controls and knobs for accurate operation.

Aesthetic Enhancement in Consumer Products

Apart from functional uses, wheel knurling tools also significantly boost the aesthetic aspect of metal components. The patterns they create offer not just practicality but also visual charm, adding sophistication to the final product. This aspect is particularly crucial in consumer products where appearance greatly influences buyer preferences. In manufacturing high-end electronics, camera bodies, or custom motorcycle components, the knurled texture offers a unique blend of function and style.

Creativity in Custom Fabrication and Metal Art

Wheel knurling tools are also highly valued in custom fabrication and metal artistry. Here, they’re employed to add detailed patterns and decorative touches to metal works. Their ability to handle various metals and create diverse patterns opens a plethora of creative possibilities, ranging from personalized jewelry to distinct architectural details.

Educational Tool for Surface Finishing Techniques

Furthermore, these tools are vital in educational environments like technical institutes, where they serve as practical tools for teaching surface finishing techniques in metalworking. They offer students hands-on experience in manipulating metal surfaces for both function and design.

Restoration in Repair and Maintenance

In the maintenance and repair sector, wheel knurling tools are essential for restoring worn-out metal components. They help revitalize grips on tools and mechanical levers, thereby extending their usability and lifespan.

Wheel knurling tools are critical in the metalworking field, cherished for their dual ability to enhance the practical and aesthetic qualities of metal products. Their application spans from industrial manufacturing to bespoke craftsmanship, playing a key role in adding both functionality and artistic value to metal creations.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Dual Wheel Knurling Tool

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.