ER Collet Set With Hight Precision Milling

ER Collet Set

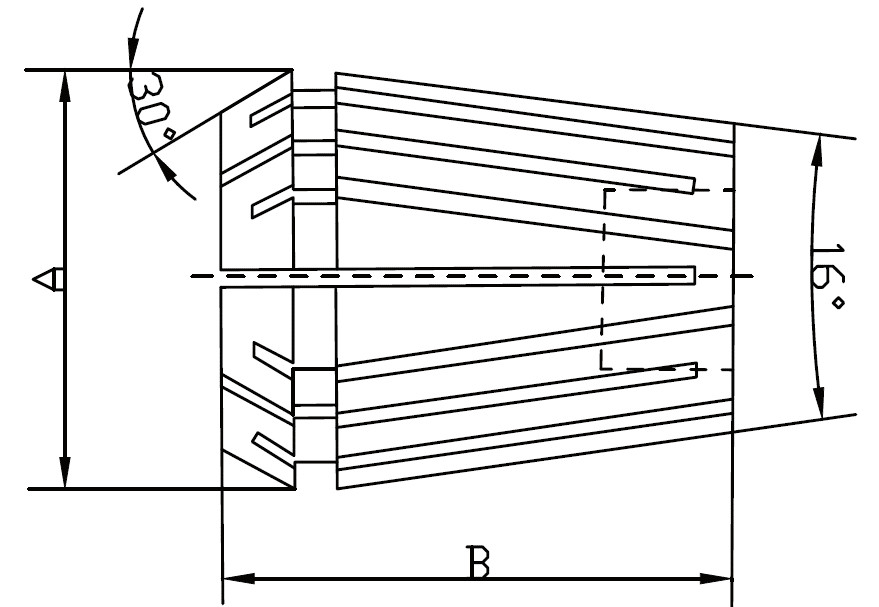

● Unique 8° taper design affords highest gripping power of this er collets set.

● True double angle, for extreme concentricity of this er collets.

● 16 Jaws giving powerful gripping and parallel clamping of this er collets.

● A unique self-releasing system is built into the ER collet and clamping nut to eliminate cutting tools sticking in collets.

Metric Size

| Size | Collet Hole Size | Pcs/ Set | Order No. |

| ER8 | 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5 | 9 | 760-0070 |

| ER11 | 1, 2, 3, 4, 5, 6, 7 | 7 | 760-0071 |

| ER11 | 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5, 6, 6.5, 7 | 13 | 760-0072 |

| ER16 | 3, 4, 5, 6, 7, 8, 9, 10 | 8 | 760-0073 |

| ER16 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10 | 10 | 760-0074 |

| ER20 | 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 10 | 760-0075 |

| ER20 | 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 12 | 760-0076 |

| ER25 | 6, 8, 10, 12, 16 | 5 | 760-0077 |

| ER25 | 4, 6, 8, 10, 12, 14, 16 | 7 | 760-0078 |

| ER25 | 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 | 13 | 760-0079 |

| ER25 | 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16 | 15 | 760-0080 |

| ER32 | 6, 8, 10, 12, 16, 20 | 6 | 760-0081 |

| ER32 | 4, 5, 6, 8, 10, 12, 13, 15, 16, 18, 20 | 11 | 760-0082 |

| ER32 | 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20 | 18 | 760-0083 |

| ER40 | 6, 8, 10, 12, 16, 20, 25 | 7 | 760-0084 |

| ER40 | 4, 5, 6, 8, 10, 12, 13, 15, 16, 18, 20, 21, 22, 25, 26 | 15 | 760-0085 |

| ER40 | 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26 | 23 | 760-0086 |

| ER50 | 12, 14, 16, 18, 20, 22, 24, 26, 28, 30, 32, 34 | 12 | 760-0087 |

Inch Size

| Size | Collet Hole Size | Pcs/ Set | Order No. |

| ER11 | 1/32, 1/16, 3/32, 1/8, 3/16, 7/32, 1/4" | 7 | 760-0088 |

| ER16 | 1/32, 1/16, 3/32, 1/8, 3/16, 7/32, 1/4, 5/16, 11/32, 3/8" | 10 | 760-0089 |

| ER20 | 1/16, 3/32, 1/8, 3/16, 7/32, 1/4, 5/16, 11/32, 3/8, 13/32, 7/16, 1/2" | 12 | 760-0090 |

| ER25 | 1/16, 3/32, 1/8, 3/16, 7/32, 1/4, 5/16, 11/32, 3/8, 13/32, 7/16, 1/2", 17/32, 9/16, 5/8" | 15 | 760-0091 |

Inch Size For ER32, 18pcs, Order Number: 760-0092

| Size | Collet Hole Size |

| ER32 | 3/32, 1/8, 3/16, 7/32, 1/4, 5/16, 11/32, 3/8, 13/32, 7/16, 1/2", 17/32, 9/16, 5/8", 21/32, 11/16, 23/32, 3/4" |

Inch Size For ER40, 23pcs, Order Number: 760-0093

| Size | Collet Hole Size |

| ER40 | 1/8, 3/16, 7/32, 1/4, 5/16, 11/32, 3/8, 13/32, 7/16, 1/2", 17/32, 9/16, 5/8", 21/32, 11/16, 3/4", 25/32, 13/16, 27/32, 7/8, 15/16, 31/32, 1" |

Versatility and Precision in Machining

ER Collets are extremely important components in the field of machine tools, primarily used for holding cutting tools. These collets are widely used in the machining industry due to their high precision and adaptability. Different models of ER Collets, such as ER8, ER11, ER16, ER20, ER25, ER32, ER40, and ER50, can adapt to various sizes and types of tools, ensuring stability and accuracy during the machining process. These collets cater to a range of machining needs from standard to high-precision, with different accuracy levels such as 0.015mm, 0.008mm, and 0.005mm.

ER Collet Selection

When selecting ER Collets, the size of the tool and the precision requirements of the machining task are the main considerations. For example, models like ER8 and ER11 are suitable for holding small tools and are often used for delicate machining tasks; while ER32 and ER40 are applicable for medium to large tools, handling heavier cutting loads. The ER50 model offers the largest size range, suitable for extra-large tools or specialized applications.

ER Collets’ Precision in Machining

Precision is another key feature of ER Collets. Collets with a precision of 0.015mm are suitable for most standard machining tasks, while those with 0.008mm and 0.005mm precision provide ideal solutions for professional applications requiring higher accuracy. For instance, in the aerospace industry or precision instrument manufacturing, these high-precision collets ensure absolute stability and accuracy of tools during high-speed rotation.

ER Collets’ Versatility in Machine Tools

The versatility of ER Collets makes them indispensable on various machine tools. These collets are suitable for tools of different diameters and provide reliable clamping force under diverse machining conditions. This flexibility and adaptability make ER Collets a preferred choice in the machining industry.

ER Collets in Modern Machining

ER Collets play a vital role in modern manufacturing and machining. They are designed to provide stable and precise holding of tools, thereby ensuring the quality and efficiency of the machining process. Whether standard or high-precision models, ER Collets meet the needs of everything from small-scale precision machining to large-scale heavy-duty machining. As industrial technology advances, ER Collets will continue to play a key role in various machine tool applications.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x ER Collet Set

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.