HSS DP Involute Gear Cutters With PA20 And PA14-1/2

Gear Cutters

● #8 cutter for 12&13 Cuts gears

● #7 cutter for 14-16 Cuts gears

● #6 cutter for 17-20 Cuts gears

● #5 cutter for 21-25 Cuts gears

● #4 cutter for 26-34 Cuts gears

● #3 cutter for 35-54 Cuts gears

● #2 cutter for 55-134 Cuts gears

● #1 cutter for 135 to Rack Cuts gears

PA20 Type

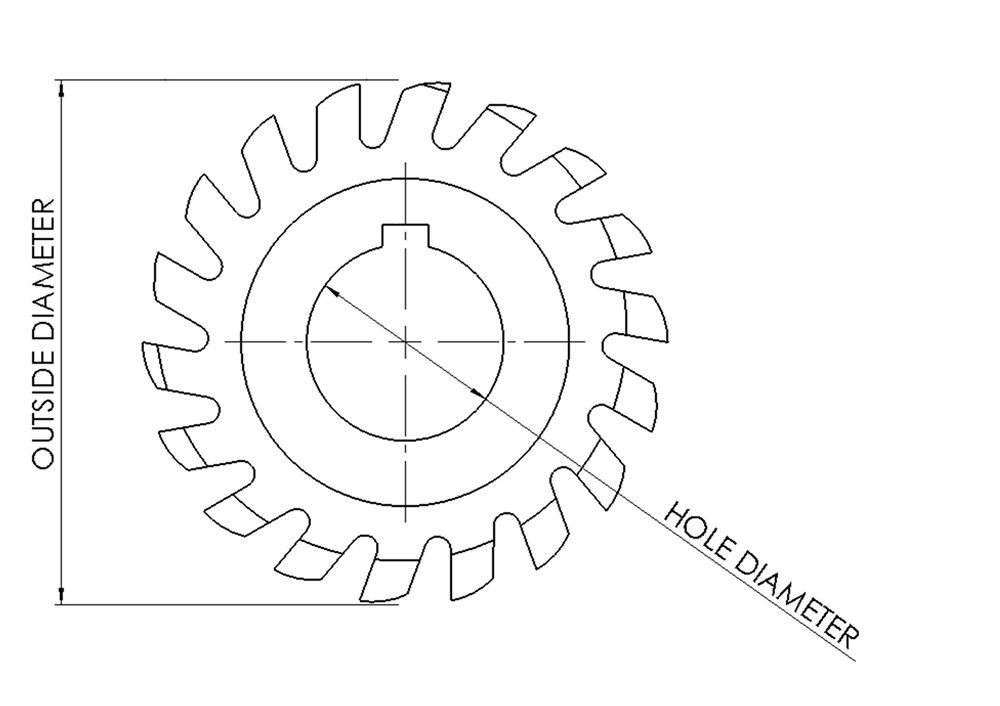

| DP | CUTTER DIA. |

HOLE DIA. |

8pcs/set |

| 4 | 3-5/8 | 1-1/4 | 660-7754 |

| 5 | 3-3/4 | 1-1/4 | 660-7755 |

| 6 | 3-1/2 | 1-1/4 | 660-7756 |

| 7 | 2-7/8 | 1 | 660-7757 |

| 8 | 2-7/8 | 1 | 660-7758 |

| 9 | 2-3/4 | 1 | 660-7759 |

| 10 | 2-3/4 | 1 | 660-7760 |

| 12 | 2-5/8 | 1 | 660-7761 |

| 14 | 2-1/2 | 1 | 660-7762 |

| 16 | 2-1/2 | 1 | 660-7763 |

| 18 | 2-3/8 | 1 | 660-7764 |

| 20 | 2-3/8 | 1 | 660-7765 |

| 24 | 2-1/4 | 1 | 660-7766 |

| 48 | 1-3/4 | 7/8 | 660-7767 |

PA14-1/2 Type

| MODULE | CUTTER DIA. |

HOLE DIA. |

8pcs/set |

| 2 | 5-3/4” | 1-1/2” | 660-7768 |

| 2-1/2 | 5-3/4 | 1-1/2 | 660-7769 |

| 3 | 5-1/4 | 1-1/4 | 660-7770 |

| 4 | 4-1/4 | 1-1/4 | 660-7771 |

| 5 | 3-5/8 | 1-1/4 | 660-7772 |

| 6 | 3-1/2 | 1-1/4 | 660-7773 |

| 7 | 2-7/8 | 1 | 660-7774 |

| 8 | 2-7/8 | 1 | 660-7775 |

| 9 | 2-3/4 | 1 | 660-7776 |

| 10 | 2-3/4 | 1 | 660-7777 |

| 11 | 2-3/8 | 1 | 660-7778 |

| 12 | 2-5/8 | 1 | 660-7779 |

| 14 | 2-1/2 | 1 | 660-7780 |

| 16 | 2-1/2 | 1 | 660-7781 |

| 18 | 2-3/8 | 1 | 660-7782 |

| 20 | 2-3/8 | 1 | 660-7783 |

| 22 | 2 | 7/8 | 660-7784 |

| 24 | 1-3/4 | 7/8 | 660-7785 |

| 26 | 1-3/4 | 7/8 | 660-7786 |

| 28 | 1-3/4 | 7/8 | 660-7787 |

| 30 | 1-3/4 | 7/8 | 660-7788 |

| 32 | 2-1/4 | 1 | 660-7789 |

| 48 | 1-3/4 | 7/8 | 660-7790 |

Application

Functions For Gear Cutter:

1. Gear Machining: Gear cutters are used to mill the profiles of gears, ensuring precise dimensions and shapes. This includes various types of gears such as spur gears, helical gears, and worm gears.

2. Gear Truing: During manufacturing, gear cutters are also utilized to true or repair the surfaces of gears to meet design requirements.

3. Precision: Gear cutters ensure that gears achieve high precision in dimensions and geometric shapes, crucial for smooth operation and performance of transmission systems.

Processing Efficiency: Using gear cutters can achieve efficient gear machining, improving production efficiency and reducing manufacturing costs.

4. Versatility: Gear cutters can be used not only for machining metal gears but also for processing gears made of materials such as plastic and wood, offering a wide range of applications.

Usage and Precautions For Gear Cutter:

Selection of Cutter: Choose the appropriate gear cutter based on the type and material of the gear to be machined, as well as the desired specifications and tolerances.

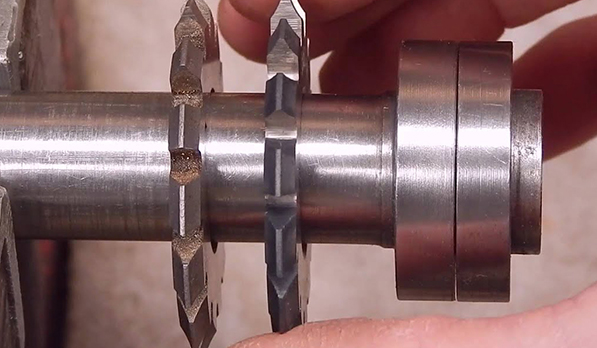

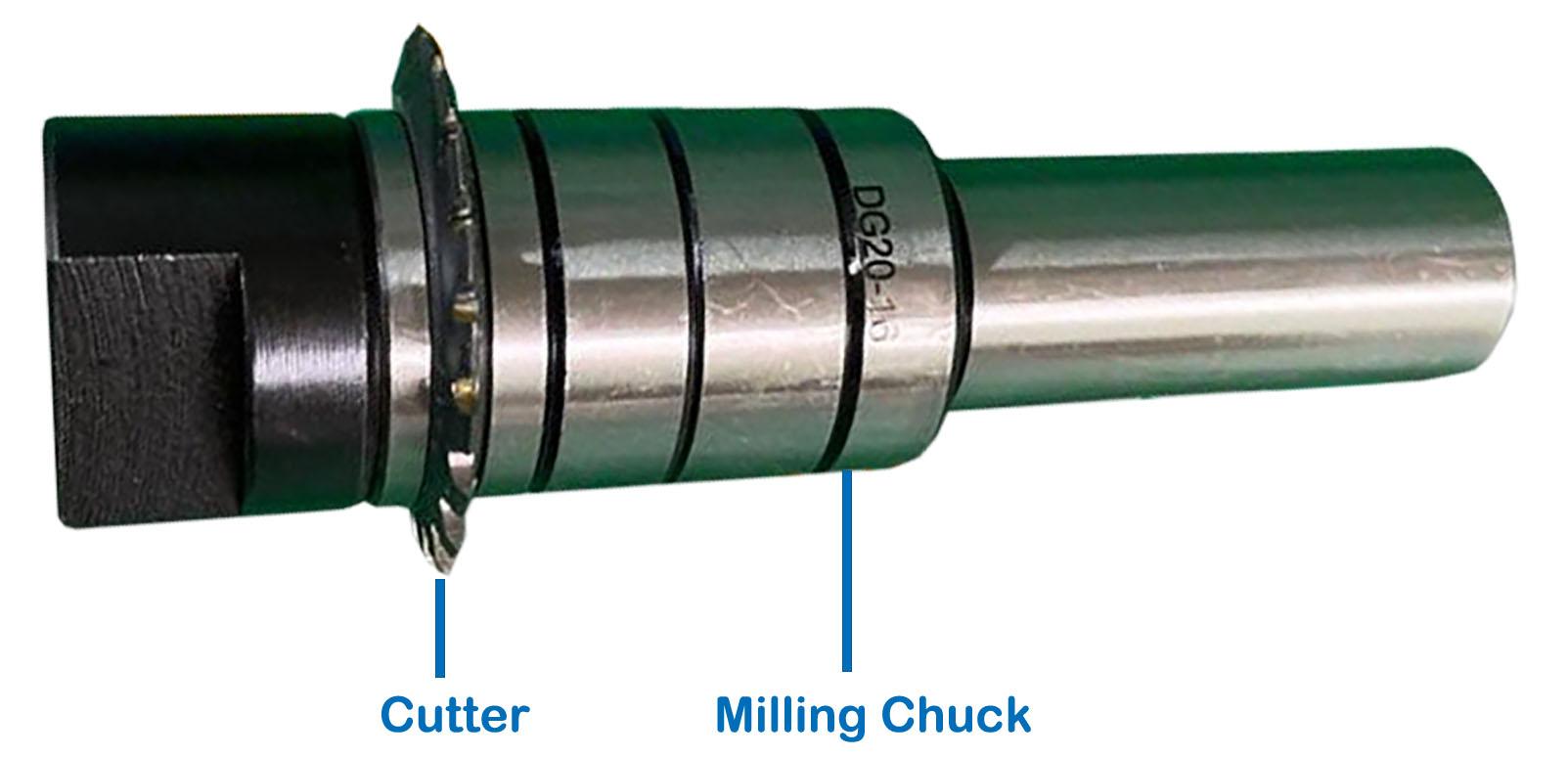

Setup: Securely mount the gear cutter on the milling machine spindle, ensuring proper alignment and concentricity.

Workpiece Fixturing: Securely clamp the workpiece on the milling machine table, ensuring stability and proper positioning for accurate machining.

Cutting Parameters: Set the cutting parameters such as speed, feed rate, and depth of cut according to the material and size of the gear, as well as the capabilities of the milling machine.

Machining Process: Carefully execute the milling process, ensuring smooth and steady movement of the milling cutter across the workpiece surface to achieve the desired gear profile and dimensions.

Coolant Use: Depending on the material being machined, use coolant or lubricant to dissipate heat and improve chip evacuation, ensuring better cutting performance and prolonging tool life.

Safety Gear: Always wear appropriate safety gear such as goggles, gloves, and ear protection to prevent injuries from flying chips, noise, and other hazards.

Tool Inspection: Regularly inspect the gear cutter for signs of wear, damage, or dullness. Replace worn or damaged cutters promptly to maintain machining quality and prevent accidents.

Machine Maintenance: Keep the milling machine in good working condition by performing regular maintenance tasks such as cleaning, lubrication, and calibration, ensuring optimal performance and safety.

Tool Handling: Handle gear cutters with care to avoid dropping or mishandling, which can lead to damage or injury. Use proper lifting techniques and storage methods to maintain tool integrity.

Chip Management: Properly manage chips and swarf generated during machining to prevent accumulation and interference with the cutting process or machine components.

Operator Training: Ensure that operators are adequately trained and familiar with the operation of gear cutters, including safety procedures and proper machining techniques.

Advantage

Efficient and Reliable Service

Wayleading Tools, your one-stop supplier for cutting tools, machinery accessories, measuring tools. As an integrated industrial powerhouse, we take immense pride in our Efficient and Reliable Service, tailored to meet the diverse needs of our esteemed clientele. Click Here For More

Good Quality

At Wayleading Tools, our commitment to Good Quality sets us apart as a formidable force in the industry. As an integrated powerhouse, we offer a diverse range of cutting-edge industrial solutions, providing you with the finest cutting tools, precise measuring instruments, and reliable machine tool accessories.Click Here For More

Competitive Pricing

Welcome to Wayleading Tools, your one-stop supplier for cutting tools, measuring tools, machinery accessories. We take immense pride in offering Competitive Pricing as one of our core advantages. Click Here For More

OEM, ODM, OBM

At Wayleading Tools, we take pride in offering comprehensive OEM (Original Equipment Manufacturer), ODM (Original Design Manufacturer), and OBM (Own Brand Manufacturer) services, catering to your unique needs and ideas.Click Here For More

Extensive Variety

Welcome to Wayleading Tools, your all-in-one destination for cutting-edge industrial solutions, where we specialize in cutting tools, measuring instruments, and machine tool accessories. Our core advantage lies in offering an Extensive Variety of products, tailored to meet the diverse needs of our esteemed clientele.Click Here For More

Matching Items

Matched Cutter: DP Gear Cutter, Spline Cutter

Matched Arbor: Milling Machine Arbor

Solution

Technical Support:

We are delighted to be your solution provider for gear cutter. We are happy to offer you technical support. Whether it's during your sales process or your customers' usage, upon receiving your technical inquiries, we will promptly address your questions. We promise to reply within 24 hours at the latest, providing you with technical solutions.Click Here For More

Customized Services:

We are pleased to offer you customized services for gear cutter. We can provide OEM services, manufacturing products according to your drawings; OBM services, branding our products with your logo; and ODM services, adapting our products according to your design requirements. Whatever customized service you require, we promise to provide you with professional customization solutions.Click Here For More

Training Services:

Whether you are the purchaser of our products or an end-user, we are more than happy to provide training service to ensure you use the products you purchased from us correctly. Our training materials come in electronic documents, videos, and online meetings, allowing you to choose the most convenient option. From your request for training to our provision of training solutions, we promise to complete the entire process within 3 days Click Here For More

After-sales Service:

Our products come with a 6-month after-sales service period. During this period, any problems not intentionally caused will be replaced or repaired free of charge. We provide round-the-clock customer service support, handling any usage queries or complaints, ensuring you have a pleasant purchasing experience. Click Here For More

Solution Design:

By providing your machining product blueprints (or assisting in creating 3D drawings if unavailable), material specifications, and mechanical details used, our product team will tailor the most suitable recommendations for cutting tools, mechanical accessories, and measuring instruments, and design comprehensive machining solutions for you. Click Here For More

Packing

Packaged in a plastic box via heat shrink bag. Then packed the gear cutter in an outer box. It can be well prevented from rusting. Also customized packing is welcomed.

Automotive Gear Efficiency

The DP Involute Gear Cutter is an essential tool in gear manufacturing, specifically designed to produce gears with accurate involute profiles. These cutters, available in a range of diametral pitch (DP) sizes, cater to diverse gear dimensions and specifications.

In the automotive industry, DP Involute Gear Cutters play a vital role in crafting complex gears for transmission systems and differentials. Their precision ensures smooth gear engagement, contributing significantly to the efficiency and performance of vehicles.

Aerospace Gear Precision

In aerospace manufacturing, these cutters are crucial for creating high-precision gears found in aircraft engines and landing gear mechanisms. They produce gears capable of enduring extreme operational conditions and loads, meeting the stringent requirements of aerospace applications.

Industrial Machinery Durability

For heavy machinery and industrial equipment production, DP Involute Gear Cutters are used to make large gears necessary for cranes, tractors, and conveyor systems. The durability and exactness of these cutters are key to the longevity and reliability of such heavy-duty machinery.

Robotics Gear Accuracy

In robotics and automation, these gear cutters are employed to manufacture smaller, high-precision gears essential for the precise movement and control needed in robotic systems.

Custom Gear Flexibility

Moreover, in custom gear fabrication, the DP Involute Gear Cutter offers the flexibility to create gears with unique or specific requirements. This adaptability is crucial for producing custom gears for specialized machinery or for replacing parts in vintage equipment.

The DP Involute Gear Cutter’s proficiency in generating gears with exact involute profiles for various sectors, including automotive, aerospace, and industrial machinery, underscores its vital role in contemporary manufacturing. Its ability to accommodate gears of varying sizes and specifications marks it as an indispensable tool in gear production processes.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x HSS DP Involute Gear Cutters

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.