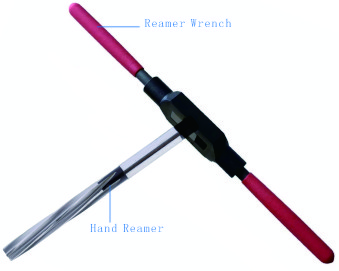

HSS Inch Hand Reamer With Straight Or Spiral Flute

Specification

We're glad you're interested in our hand reamer. We offer two material types: High-Speed Steel (HSS) and 9CrSi. While 9CrSi is suitable for manual use only, HSS can be used both manually and with machines.

Any further info. Feel free to contact us.

Inch

| SIZE IN |

FLUTE LENGTH |

OVERALL LENGTH |

STRAIGHT FLUTE | SPIRAL FLUTE | ||

| HSS | HSS-TIN | HSS | HSS-TIN | |||

| 1/8 | 1-1/2 | 3 | 660-6720 | 660-6749 | 660-6778 | 660-6807 |

| 5/32 | 1-5/8 | 3-1/4 | 660-6721 | 660-6750 | 660-6779 | 660-6808 |

| 3/16 | 1-3/4 | 3-1/2 | 660-6722 | 660-6751 | 660-6780 | 660-6809 |

| 7/32 | 1-7/8 | 3-3/4 | 660-6723 | 660-6752 | 660-6781 | 660-6810 |

| 1/4 | 2 | 4 | 660-6724 | 660-6753 | 660-6782 | 660-6811 |

| 9/32 | 2-1/8 | 4-1/4 | 660-6725 | 660-6754 | 660-6783 | 660-6812 |

| 5/16 | 2-1/4 | 4-1/2 | 660-6726 | 660-6755 | 660-6784 | 660-6813 |

| 11/32 | 2-3/8 | 4-3/4 | 660-6727 | 660-6756 | 660-6785 | 660-6814 |

| 3/8 | 2-1/2 | 5 | 660-6728 | 660-6757 | 660-6786 | 660-6815 |

| 13/32 | 2-5/8 | 5-1/4 | 660-6729 | 660-6758 | 660-6787 | 660-6816 |

| 7/16 | 2-3/4 | 5-1/2 | 660-6730 | 660-6759 | 660-6788 | 660-6817 |

| 15/32 | 2-7/8 | 5-3/4 | 660-6731 | 660-6760 | 660-6789 | 660-6818 |

| 1/2 | 3 | 6 | 660-6732 | 660-6761 | 660-6790 | 660-6819 |

| 9/16 | 3-1/4 | 6-1/2 | 660-6733 | 660-6762 | 660-6791 | 660-6820 |

| 5/8 | 3-1/2 | 7 | 660-6734 | 660-6763 | 660-6792 | 660-6821 |

| 11/16 | 3-7/8 | 7-3/4 | 660-6735 | 660-6764 | 660-6793 | 660-6822 |

| 3/4 | 4-3/16 | 8-3/8 | 660-6736 | 660-6765 | 660-6794 | 660-6823 |

| 13/16 | 4-9/16 | 9-1/8 | 660-6737 | 660-6766 | 660-6795 | 660-6824 |

| 7/8 | 4-7/8 | 9-3/4 | 660-6738 | 660-6767 | 660-6796 | 660-6825 |

| 15/16 | 5-1/8 | 10-1/4 | 660-6739 | 660-6768 | 660-6797 | 660-6826 |

| 1 | 5-7/16 | 10-7/8 | 660-6740 | 660-6769 | 660-6798 | 660-6827 |

| 1-1/16 | 5-5/8 | 11-1/4 | 660-6741 | 660-6770 | 660-6799 | 660-6828 |

| 1-1/8 | 5-13/16 | 11-5/8 | 660-6742 | 660-6771 | 660-6800 | 660-6829 |

| 1-3/16 | 6 | 12 | 660-6743 | 660-6772 | 660-6801 | 660-6830 |

| 1-1/4 | 6-1/8 | 12-1/4 | 660-6744 | 660-6773 | 660-6802 | 660-6831 |

| 1-5/16 | 6-1/4 | 12-1/2 | 660-6745 | 660-6774 | 660-6803 | 660-6832 |

| 1-3/8 | 6-5/16 | 12-5/8 | 660-6746 | 660-6775 | 660-6804 | 660-6833 |

| 1-7/16 | 6-7/16 | 12-7/8 | 660-6747 | 660-6776 | 660-6805 | 660-6834 |

| 1-1/2 | 6-1/2 | 13 | 660-6748 | 660-6777 | 660-6806 | 660-6835 |

Application

Fuction For Hand Reamer:

Used for the final sizing of holes.

Hand reamer is used for the final sizing of holes, to accurately enlarge or shape existing holes. It features a set of cutting edges at the end. When in use, the reamer is manually rotated, and the cutting edges gradually remove material from the hole walls to achieve the desired diameter and surface smoothness. Hand reamers are commonly employed in processes requiring higher precision and surface quality.

Usage and Precautions For ER Collets:

When using hand reamers to bore a hole, start by drilling a hole in the workpiece with a slightly smaller diameter than required. Next, select the appropriate size of hand reamer. Before using the hand reamer, ensure to apply cutting fluid to the surface of the workpiece and the reamer tool to reduce friction and wear, while also cooling the tool and workpiece.

Insert the hand reamer into the pre-drilled hole and use suitable reamer wrench rotating force to gradually enlarge the diameter of the hole. During this process, periodically pause to check the dimensions of the hole to ensure they meet the requirements. If necessary, add cutting fluid repeatedly to maintain smooth cutting.

Upon completion of the machining, remove the hand reamer from the hole and clean the surface of the workpiece and the reamer tool to remove cutting fluid and metal chips. Finally, perform necessary measurements and inspections to ensure the dimensions and quality of the hole meet the requirements.

Advantage

Efficient and Reliable Service

Wayleading Tools, your one-stop supplier for cutting tools, machinery accessories, measuring tools. As an integrated industrial powerhouse, we take immense pride in our Efficient and Reliable Service, tailored to meet the diverse needs of our esteemed clientele. Click Here For More

Good Quality

At Wayleading Tools, our commitment to Good Quality sets us apart as a formidable force in the industry. As an integrated powerhouse, we offer a diverse range of cutting-edge industrial solutions, providing you with the finest cutting tools, precise measuring instruments, and reliable machine tool accessories.Click Here For More

Competitive Pricing

Welcome to Wayleading Tools, your one-stop supplier for cutting tools, measuring tools, machinery accessories. We take immense pride in offering Competitive Pricing as one of our core advantages. Click Here For More

OEM, ODM, OBM

At Wayleading Tools, we take pride in offering comprehensive OEM (Original Equipment Manufacturer), ODM (Original Design Manufacturer), and OBM (Own Brand Manufacturer) services, catering to your unique needs and ideas.Click Here For More

Extensive Variety

Welcome to Wayleading Tools, your all-in-one destination for cutting-edge industrial solutions, where we specialize in cutting tools, measuring instruments, and machine tool accessories. Our core advantage lies in offering an Extensive Variety of products, tailored to meet the diverse needs of our esteemed clientele.Click Here For More

Application

Fuction For Hand Reamer:

Used for the final sizing of holes.

Hand reamer is used for the final sizing of holes, to accurately enlarge or shape existing holes. It features a set of cutting edges at the end. When in use, the reamer is manually rotated, and the cutting edges gradually remove material from the hole walls to achieve the desired diameter and surface smoothness. Hand reamers are commonly employed in processes requiring higher precision and surface quality.

Usage and Precautions For ER Collets:

When using hand reamers to bore a hole, start by drilling a hole in the workpiece with a slightly smaller diameter than required. Next, select the appropriate size of hand reamer. Before using the hand reamer, ensure to apply cutting fluid to the surface of the workpiece and the reamer tool to reduce friction and wear, while also cooling the tool and workpiece.

Insert the hand reamer into the pre-drilled hole and use suitable reamer wrench rotating force to gradually enlarge the diameter of the hole. During this process, periodically pause to check the dimensions of the hole to ensure they meet the requirements. If necessary, add cutting fluid repeatedly to maintain smooth cutting.

Upon completion of the machining, remove the hand reamer from the hole and clean the surface of the workpiece and the reamer tool to remove cutting fluid and metal chips. Finally, perform necessary measurements and inspections to ensure the dimensions and quality of the hole meet the requirements.

Advantage

Efficient and Reliable Service

Wayleading Tools, your one-stop supplier for cutting tools, machinery accessories, measuring tools. As an integrated industrial powerhouse, we take immense pride in our Efficient and Reliable Service, tailored to meet the diverse needs of our esteemed clientele. Click Here For More

Good Quality

At Wayleading Tools, our commitment to Good Quality sets us apart as a formidable force in the industry. As an integrated powerhouse, we offer a diverse range of cutting-edge industrial solutions, providing you with the finest cutting tools, precise measuring instruments, and reliable machine tool accessories.Click Here For More

Competitive Pricing

Welcome to Wayleading Tools, your one-stop supplier for cutting tools, measuring tools, machinery accessories. We take immense pride in offering Competitive Pricing as one of our core advantages. Click Here For More

OEM, ODM, OBM

At Wayleading Tools, we take pride in offering comprehensive OEM (Original Equipment Manufacturer), ODM (Original Design Manufacturer), and OBM (Own Brand Manufacturer) services, catering to your unique needs and ideas.Click Here For More

Extensive Variety

Welcome to Wayleading Tools, your all-in-one destination for cutting-edge industrial solutions, where we specialize in cutting tools, measuring instruments, and machine tool accessories. Our core advantage lies in offering an Extensive Variety of products, tailored to meet the diverse needs of our esteemed clientele.Click Here For More

Matching Items

Solution

Technical Support:

We are delighted to be your solution provider for ER collet. We are happy to offer you technical support. Whether it's during your sales process or your customers' usage, upon receiving your technical inquiries, we will promptly address your questions. We promise to reply within 24 hours at the latest, providing you with technical solutions.

Customized Services:

We are pleased to offer you customized services for ER collet. We can provide OEM services, manufacturing products according to your drawings; OBM services, branding our products with your logo; and ODM services, adapting our products according to your design requirements. Whatever customized service you require, we promise to provide you with professional customization solutions.

Training Services:

Whether you are the purchaser of our products or an end-user, we are more than happy to provide training service to ensure you use the products you purchased from us correctly. Our training materials come in electronic documents, videos, and online meetings, allowing you to choose the most convenient option. From your request for training to our provision of training solutions, we promise to complete the entire process within 3 days

After-sales Service:

Our products come with a 6-month after-sales service period. During this period, any problems not intentionally caused will be replaced or repaired free of charge. We provide round-the-clock customer service support, handling any usage queries or complaints, ensuring you have a pleasant purchasing experience.

Solution Design:

By providing your machining product blueprints (or assisting in creating 3D drawings if unavailable), material specifications, and mechanical details used, our product team will tailor the most suitable recommendations for cutting tools, mechanical accessories, and measuring instruments, and design comprehensive machining solutions for you.

Packing

Packaged in a plastic box, then packed in an outer box. It can be well protect the hand reamers.

Also customized packing is welcomed.

Aerospace Assembly Precision

Hand Reamers, especially those crafted from high-speed steel (HSS), are critical in precision machining and metalworking for their precise finishing capabilities. A primary use of hand reamers is to refine machined holes, ensuring they meet exact dimensions and have smooth surfaces, a necessity in sectors like aerospace, where precise hole dimensions are integral for assembling aircraft parts.

Automotive Engine Finishing

In automotive manufacturing, hand reamers are essential for finely finishing critical engine parts like block holes and cylinder bores, ensuring a flawless fit and enhancing engine performance and durability. Similarly, in producing machinery and heavy equipment, these tools are key in fitting shafts and gears accurately, essential for the smooth operation of heavy-duty machines.

Machinery and Heavy Equipment Accuracy

Hand reamers are also invaluable in metal fabrication and bespoke machining, perfect for tasks requiring high precision and finish, such as crafting custom components. The manual control offered by hand reamers makes them ideal for detailed and delicate tasks.

Metal Fabrication and Custom Machining

Beyond manufacturing, hand reamers are useful in maintenance and repair, particularly where powered machines are unsuitable or unavailable, allowing for precise on-site repairs.

Maintenance and Repair Versatility

The combination of versatility, precision, and portability makes hand reamers vital across various industries for precise hole finishing. Their role in assuring component accuracy is essential for creating high-quality, reliable, and functional products.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x HSS Inch Hand Reamer

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.