Metric Thread Plug Gauge 6H Accuracy With Go & NO Go

Metric Thread Ring Gauge

● Strictly made in accordance with DIN ISO 1502.

● With Go&No-GO ends.

● Grade 6H

● Made of premium steel, hardened, cryogenic treatment.

● Stable product diamensions, superior surface finish, wear resistance for long service life.

● With inspection certificate.

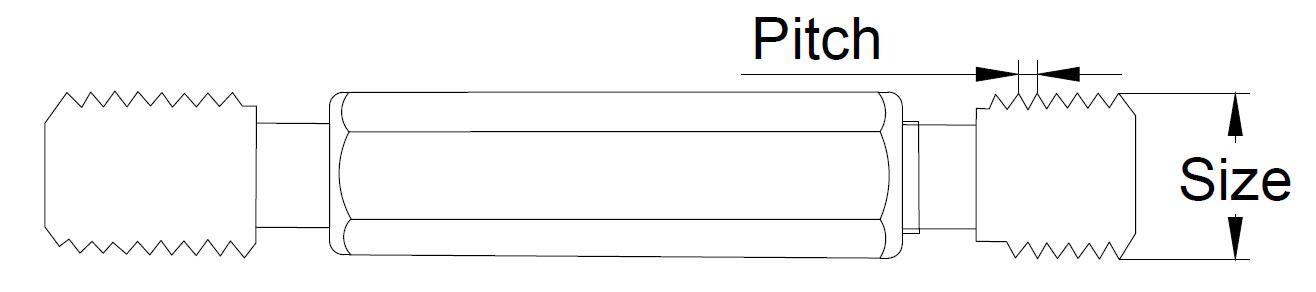

| Size | Pitch | Accuracy | Order No. |

| M2 | 0.25 | 6H | 860-0032 |

| 0.4 | 860-0033 | ||

| M2.2 | 0.25 | 6H | 860-0034 |

| 0.45 | 860-0035 | ||

| M2.5 | 0.35 | 6H | 860-0036 |

| 0.45 | 860-0037 | ||

| M3.5 | 0.35 | 6H | 860-0038 |

| 0.6 | 860-0039 | ||

| M4 | 0.5 | 6H | 860-0040 |

| 0.7 | 860-0041 | ||

| M5 | 0.5 | 6H | 860-0042 |

| 0.8 | 860-0043 | ||

| M6 | 0.5 | 6H | 860-0044 |

| 0.75 | 860-0045 | ||

| 1 | 860-0046 | ||

| M7 | 0.5 | 6H | 860-0047 |

| 0.75 | 860-0048 | ||

| 1 | 860-0049 | ||

| M8 | 0.5 | 6H | 860-0050 |

| 0.75 | 860-0051 | ||

| 1 | 860-0052 | ||

| 1.25 | 860-0053 | ||

| M9 | 0.5 | 6H | 860-0054 |

| 0.75 | 860-0055 | ||

| 1 | 860-0056 | ||

| 1.25 | 860-0057 | ||

| M10 | 0.5 | 6H | 860-0058 |

| 0.75 | 860-0059 | ||

| 1 | 860-0060 | ||

| 1.25 | 860-0061 | ||

| 1.5 | 860-0062 | ||

| M11 | 0.5 | 6H | 860-0063 |

| 0.75 | 860-0064 | ||

| 1 | 860-0065 | ||

| 1.25 | 860-0066 | ||

| 1.5 | 860-0067 | ||

| M12 | 0.5 | 6H | 860-0068 |

| 0.75 | 860-0069 | ||

| 1 | 860-0070 | ||

| 1.25 | 860-0071 | ||

| 1.5 | 860-0072 | ||

| 1.75 | 860-0073 | ||

| M14 | 0.5 | 6H | 860-0074 |

| 0.75 | 860-0075 | ||

| 1 | 860-0076 | ||

| 1.25 | 860-0077 | ||

| 1.5 | 860-0078 | ||

| 2 | 860-0079 | ||

| M15 | 1 | 6H | 860-0080 |

| 1.5 | 860-0081 | ||

| M16 | 0.5 | 6H | 860-0082 |

| 0.75 | 860-0083 | ||

| 1 | 860-0084 | ||

| 1.25 | 860-0085 | ||

| 1.5 | 860-0086 | ||

| 2 | 860-0087 | ||

| M17 | 1 | 6H | 860-0088 |

| 1.5 | 860-0089 | ||

| M18 | 0.5 | 6H | 860-0090 |

| 0.75 | 860-0091 | ||

| 1 | 860-0092 | ||

| 1.5 | 860-0093 | ||

| 2 | 860-0094 | ||

| 2.5 | 860-0095 | ||

| M20 | 0.5 | 6H | 860-0096 |

| 0.75 | 860-0097 | ||

| 1 | 860-0098 | ||

| 1.5 | 860-0099 | ||

| 2 | 860-0100 | ||

| 2.5 | 860-0101 | ||

| M22 | 0.5 | 6H | 860-0102 |

| 0.75 | 860-0103 | ||

| 1 | 860-0104 | ||

| 1.5 | 860-0105 | ||

| 2 | 860-0106 | ||

| 2.5 | 860-0107 | ||

| M24 | 0.5 | 6H | 860-0108 |

| 0.75 | 860-0109 | ||

| 1 | 860-0110 | ||

| 1.5 | 860-0111 | ||

| 2 | 860-0112 | ||

| 3 | 860-0113 | ||

| M27 | 0.5 | 6H | 860-0114 |

| 0.75 | 860-0115 | ||

| 1 | 860-0116 | ||

| 1.5 | 860-0117 | ||

| 2 | 860-0118 | ||

| 3 | 860-0119 | ||

| M30 | 0.75 | 6H | 860-0120 |

| 1 | 860-0121 | ||

| 1.5 | 860-0122 | ||

| 2 | 860-0123 | ||

| 3 | 860-0124 | ||

| 3.5 | 860-0125 |

| Size | Pitch | Accuracy | Order No. |

| M33 | 0.75 | 6H | 860-0126 |

| 1 | 860-0127 | ||

| 1.5 | 860-0128 | ||

| 2 | 860-0129 | ||

| 3 | 860-0130 | ||

| 3.5 | 860-0131 | ||

| M36 | 0.75 | 6H | 860-0132 |

| 1 | 860-0133 | ||

| 1.5 | 860-0134 | ||

| 2 | 860-0135 | ||

| 3 | 860-0136 | ||

| 4 | 860-0137 | ||

| M39 | 0.75 | 6H | 860-0138 |

| 1 | 860-0139 | ||

| 1.5 | 860-0140 | ||

| 2 | 860-0141 | ||

| 3 | 860-0142 | ||

| 4 | 860-0143 | ||

| M42 | 1 | 6H | 860-0144 |

| 1.5 | 860-0145 | ||

| 2 | 860-0146 | ||

| 3 | 860-0147 | ||

| 4 | 860-0148 | ||

| 4.5 | 860-0149 | ||

| M45 | 1 | 6H | 860-0150 |

| 1.5 | 860-0151 | ||

| 2 | 860-0152 | ||

| 3 | 860-0153 | ||

| 4 | 860-0154 | ||

| 4.5 | 860-0155 | ||

| M48 | 1 | 6H | 860-0156 |

| 1.5 | 860-0157 | ||

| 2 | 860-0158 | ||

| 3 | 860-0159 | ||

| 4 | 860-0160 | ||

| 5 | 860-0161 | ||

| M52 | 1 | 6H | 860-0162 |

| 1.5 | 860-0163 | ||

| 2 | 860-0164 | ||

| 3 | 860-0165 | ||

| 4 | 860-0166 | ||

| 5 | 860-0167 | ||

| M56 | 1 | 6H | 860-0168 |

| 1.5 | 860-0169 | ||

| 2 | 860-0170 | ||

| 3 | 860-0171 | ||

| 4 | 860-0172 | ||

| 5.5 | 860-0173 | ||

| M60 | 1 | 6H | 860-0174 |

| 1.5 | 860-0175 | ||

| 2 | 860-0176 | ||

| 3 | 860-0177 | ||

| 4 | 860-0178 | ||

| 5.5 | 860-0179 | ||

| M64 | 6 | 6H | 860-0180 |

| 4 | 860-0181 | ||

| 3 | 860-0182 | ||

| 2 | 860-0183 | ||

| 1.5 | 860-0184 | ||

| 1 | 860-0185 | ||

| M68 | 1 | 6H | 860-0186 |

| 1.5 | 860-0187 | ||

| 2 | 860-0188 | ||

| 3 | 860-0189 | ||

| 4 | 860-0190 | ||

| 6 | 860-0191 | ||

| M72 | 1 | 6H | 860-0192 |

| 1.5 | 860-0193 | ||

| 2 | 860-0194 | ||

| 3 | 860-0195 | ||

| 4 | 860-0196 | ||

| 6 | 860-0197 | ||

| M76 | 1 | 6H | 860-0198 |

| 1.5 | 860-0199 | ||

| 2 | 860-0200 | ||

| 3 | 860-0201 | ||

| 4 | 860-0202 | ||

| 6 | 860-0203 | ||

| M80 | 1 | 6H | 860-0204 |

| 1.5 | 860-0205 | ||

| 2 | 860-0206 | ||

| 3 | 860-0207 | ||

| 4 | 860-0208 | ||

| 6 | 860-0209 |

Importance and Applications

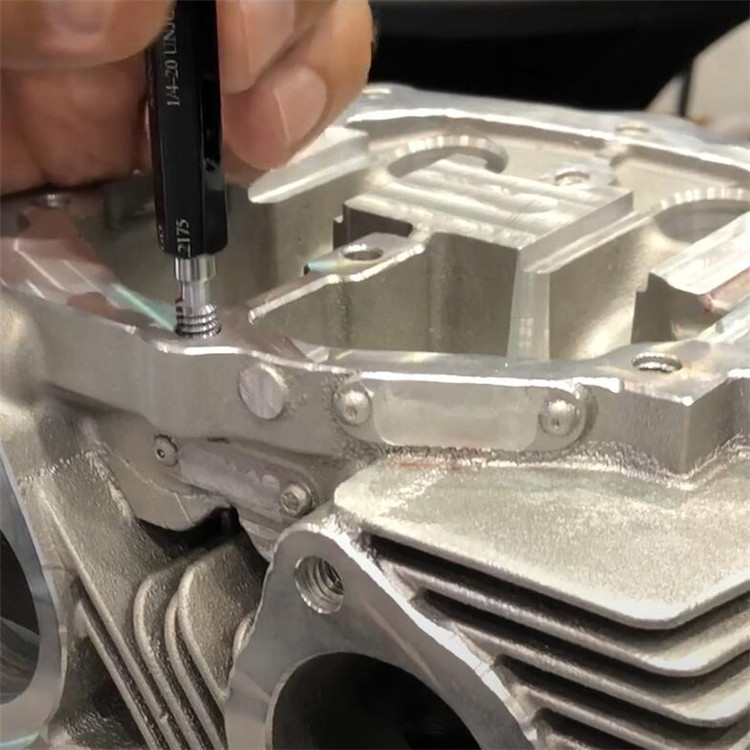

The Metric Thread Plug Gauge is a critical instrument in the manufacturing industry, primarily used for accurately measuring and verifying the precision of internal threads in various components. Designed according to international metric standards, these gauges are available in a wide range of sizes and thread pitches, making them versatile for different applications.

The gauge is typically made of high-grade steel or other durable materials to resist wear and maintain accuracy over time. It features two distinct ends: the ‘go’ end and the ‘no-go’ end. The ‘go’ end is designed to fit smoothly into the threaded hole if the threads are within the specified size limits and tolerance levels. On the other hand, the ‘no-go’ end is slightly larger and should not be able to fully enter the threaded hole if the threading is correctly sized. This dual-end design ensures a comprehensive assessment of the thread’s dimensions and quality.

Design and Materials

Metric Thread Plug Gauges are indispensable in ensuring that threaded parts conform to precise specifications, crucial for components that must fit together with exacting precision. They are commonly used in industries such as automotive, aerospace, and machinery manufacturing, where the integrity of threaded joints is vital.

Quality Control Role

Beyond their practical applications, these gauges also play a significant role in quality control processes. They help in maintaining consistency in production lines and in reducing the margin of error in manufacturing. By ensuring that each threaded part meets the required standards, Metric Thread Plug Gauges contribute to the overall reliability and performance of the final products.

Significance in Manufacturing

Metric Thread Plug Gauges are essential tools in the manufacturing sector, offering a reliable and precise method for inspecting the accuracy of internal threads. Their use is critical in maintaining quality and consistency in products that rely on the exact fit and function of threaded components.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Metric Thread Plug Gauge

1 x Protective Case

1 x Test Report By Our Factory

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.