In the modern CNC machining industry, pull studs serve as a critical connection component between the CNC tool holder and the machine, playing an essential role in the overall process. Though it may seem like a standard product, its significance cannot be overlooked, as it directly impacts machining accuracy, efficiency, and safety.

The primary function of a pull stud is to securely fasten the tool to the holder by the clamping force generated by the machine spindle. This ensures that the tool remains stable during high-speed rotation and complex cutting operations. To achieve this, a high-quality pull stud must possess excellent material properties, precise manufacturing, and a design that meets application requirements.

Material Selection Ensures Durability

Typically, pull studs are made from high-strength alloy steel, a material known for its superior tensile strength, hardness, and wear resistance. Through rigorous heat treatment processes, pull studs maintain their mechanical properties under prolonged high-load use, preventing failure due to material fatigue. This material choice ensures that the pull stud can maintain its functional stability and safety in various machining environments.

Precision Manufacturing Enhances Machining Accuracy

Every detail of a pull stud is meticulously crafted during manufacturing, with particular attention to the threading process. Precise threading not only ensures a tight fit between the pull stud and the tool holder but also effectively reduces vibration and displacement of the tool during cutting. This, in turn, improves the surface quality and dimensional accuracy of the workpiece. These seemingly small details collectively have a significant impact on the final machining results.

Optimized Design for Broad Applications

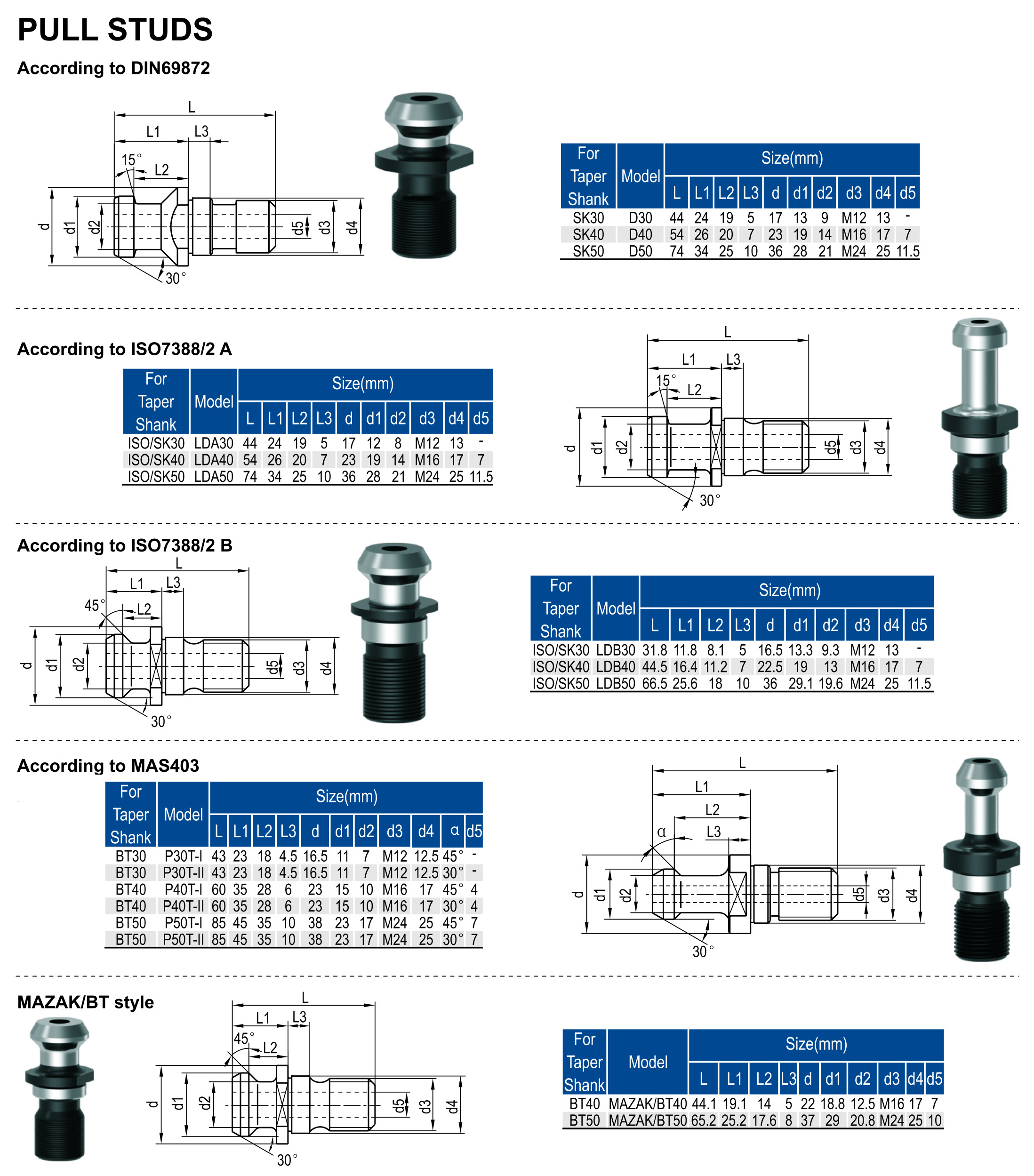

Although pull studs may appear simple, their design requires careful consideration. The design of the head directly affects the speed and stability of tool installation. An optimized head design can reduce tool change time, improve production efficiency, and ensure that the tool remains securely fastened during high-load machining. Additionally, the structural design of the pull stud must account for its overall stability under significant tensile forces to prevent breakage or deformation, which is crucial for maintaining machining safety.

Standard Product with Reliable Quality

While pull studs are considered a standard product in CNC machining, their quality must not be taken lightly. Each pull stud undergoes rigorous testing before leaving the factory to ensure it meets industry standards and customer requirements. The advantage of standard products lies in their long-term market validation, offering reliable quality and performance that provide consistent support for users.

In the daily application of CNC machining, the pull stud, though a small component, is an indispensable part of the entire machining system. It provides solid assurance for tool stability and machining accuracy, making it a key element in the operation of CNC machines. When selecting pull studs, manufacturers should prioritize their quality and performance to ensure smooth machining processes.

Contact: sales@wayleading.com

Post time: Sep-01-2024