Functions

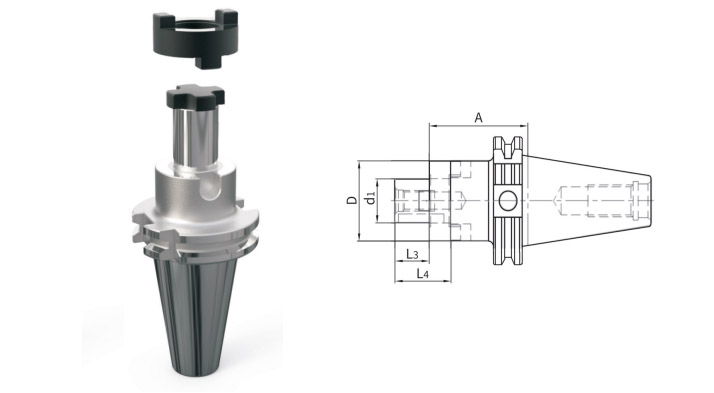

Stable Clamping of Tools:

The JT model combination face mill adapter tool holder, with its unique groove design, can firmly clamp milling cutters with longitudinal or transverse grooves. This ensures that the tool remains stable during high-speed cutting, preventing tool loosening or displacement, thereby improving machining precision and surface quality.

Enhanced Processing Efficiency:

This tool holder supports quick tool changes, reducing tool change times and machine downtime, significantly improving overall processing efficiency.

Reduced Vibration and Heat:

The stable clamping reduces tool vibration during machining and lowers the heat generated during cutting. This helps to extend tool life and maintain good surface quality.

Adaptability to Various Tools:

The JT model tool holder is compatible with various types of milling cutters, especially those with longitudinal or transverse grooves, such as shell end mills and slitting saws. This makes it highly versatile for complex machining tasks.

Usage Method

Installing the Tool Holder:

Mount the JT model combination face mill adapter tool holder onto the spindle of the milling machine. Ensure a tight connection between the tool holder and the spindle to avoid instability.

Clamping the Milling Cutter:

1. Select an appropriate milling cutter with longitudinal or transverse grooves, such as a shell end mill or slitting saw.

2. Insert the shank of the milling cutter into the JT tool holder's clamping hole, ensuring the grooves align.

3. Use the tool holder's locking mechanism (e.g., screws or nuts) to securely fasten the milling cutter.

Adjusting Tool Position:

Adjust the extension length and angle of the tool according to machining needs to ensure the optimal cutting position.

Starting Machining:

After confirming that the tool is securely installed, start the milling machine to begin the machining process. The tool holder will provide stable support to ensure high-precision cutting results.

Usage Precautions

Ensure Groove Matching:

When clamping the milling cutter, make sure the tool’s grooves match the grooves on the JT tool holder. Mismatched grooves may lead to unstable clamping, affecting machining precision and increasing safety risks.

Regular Inspection of Tool Holder and Tool Condition:

Before and after use, inspect the tool holder and milling cutter for any wear or damage. If issues are found, replace or repair them promptly to ensure the reliability of the clamping system.

Avoid Overload Usage:

Follow the rated load range of the tool holder and tool to avoid using it under high-load conditions. Overloading may cause deformation of the tool holder or damage to the tool, affecting machining quality and equipment lifespan.

Maintain Cleanliness:

After each use, clean the tool holder and tools to remove chips and debris. Keeping the clamping surfaces clean helps maintain good clamping performance and prevents instability due to dirt accumulation.

Proper Operation of the Locking Mechanism:

When locking the tool, apply even pressure to avoid over-tightening or under-tightening on one side. Ensure the tool does not move or vibrate during the machining process.

Regular Maintenance:

Perform regular maintenance on the JT tool holder, including checking the fastening elements of the clamping mechanism for looseness, and lubricating moving parts to keep them in good working condition. This ensures the tool holder remains in optimal operating condition.