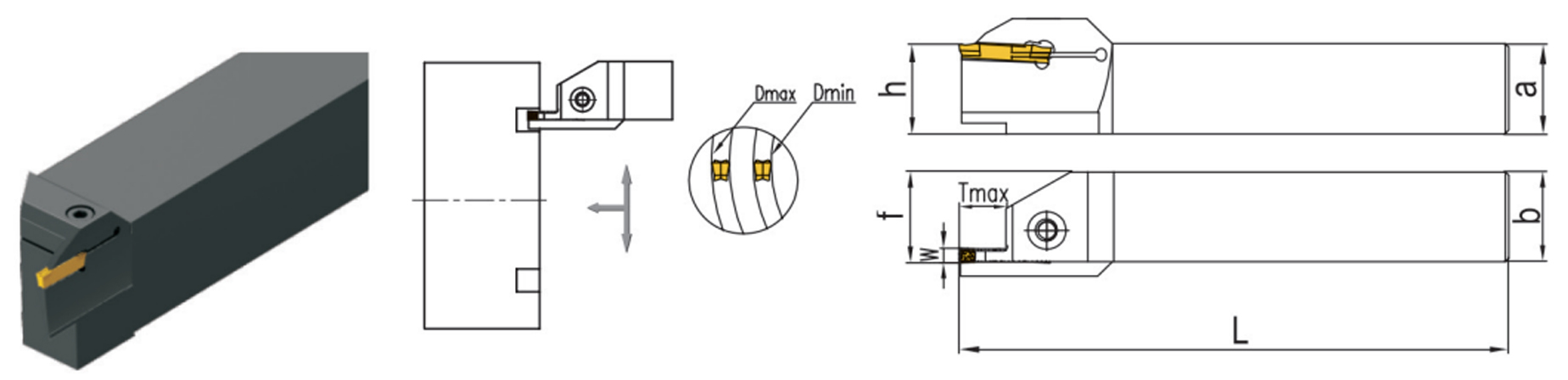

A Face Grooving Tool Holder is used to cut precise grooves on the end face of a workpiece. It is primarily designed to create ring grooves for applications that require sealing, assembly, or weight reduction. As a key tool in precision machining, the Face Grooving Tool Holder is widely used in industries such as automotive manufacturing, aerospace, and heavy machinery. Its sturdy design and high rigidity effectively counteract vibrations during the cutting process, providing stable and accurate face grooving performance.

Usage

Installing the Face Grooving Tool Holder: First, mount the Face Grooving Tool Holder onto the tool post of the machine, ensuring that the tool aligns with the center of the workpiece. Proper alignment not only improves cutting accuracy but also extends the life of the tool.

Setting Cutting Parameters: Adjust the cutting speed, feed rate, and depth of cut for the Face Grooving Tool Holder according to the workpiece material, hardness, and groove width. Accurate parameter settings help enhance grooving quality while reducing tool wear.

Precise Alignment and Machining: When starting the machine, ensure that the tip of the Face Grooving Tool Holder aligns precisely with the desired position on the workpiece. For high-precision machining, using a centering gauge can help achieve better accuracy. During the machining process, gradually increase the feed rate to reach the set depth, ensuring stable grooving with the tool.

Precautions

Choosing Tool Material: Different workpiece materials require different tool materials. For hard materials, it is recommended to use carbide inserts in the Face Grooving Tool Holder, while high-speed steel inserts are suitable for softer materials to balance cost and performance.

Temperature Control: During face grooving, friction may cause the tool temperature to rise, increasing wear. Applying coolant effectively reduces the cutting temperature and extends tool life.

Appropriate Cutting Depth: The depth of the groove should be controlled within the safe range of the tool; excessive cutting can damage or break the Face Grooving Tool Holder. Additionally, plan the cutting path carefully to avoid burrs on the groove edges.

Regular Tool Inspection: The Face Grooving Tool Holder’s cutting edge may wear out over prolonged use, so regular inspections and replacements or regrinding are essential to ensure machining quality and tool life.

Preventing Vibration: The Face Grooving Tool Holder must remain stable during machining to avoid rough groove surfaces caused by vibration. Ensure that the tool is firmly installed and the machine is stable to minimize vibration and maintain machining accuracy.

Contact: Jason Lee

Email: jason@wayleading.com

Post time: Nov-08-2024