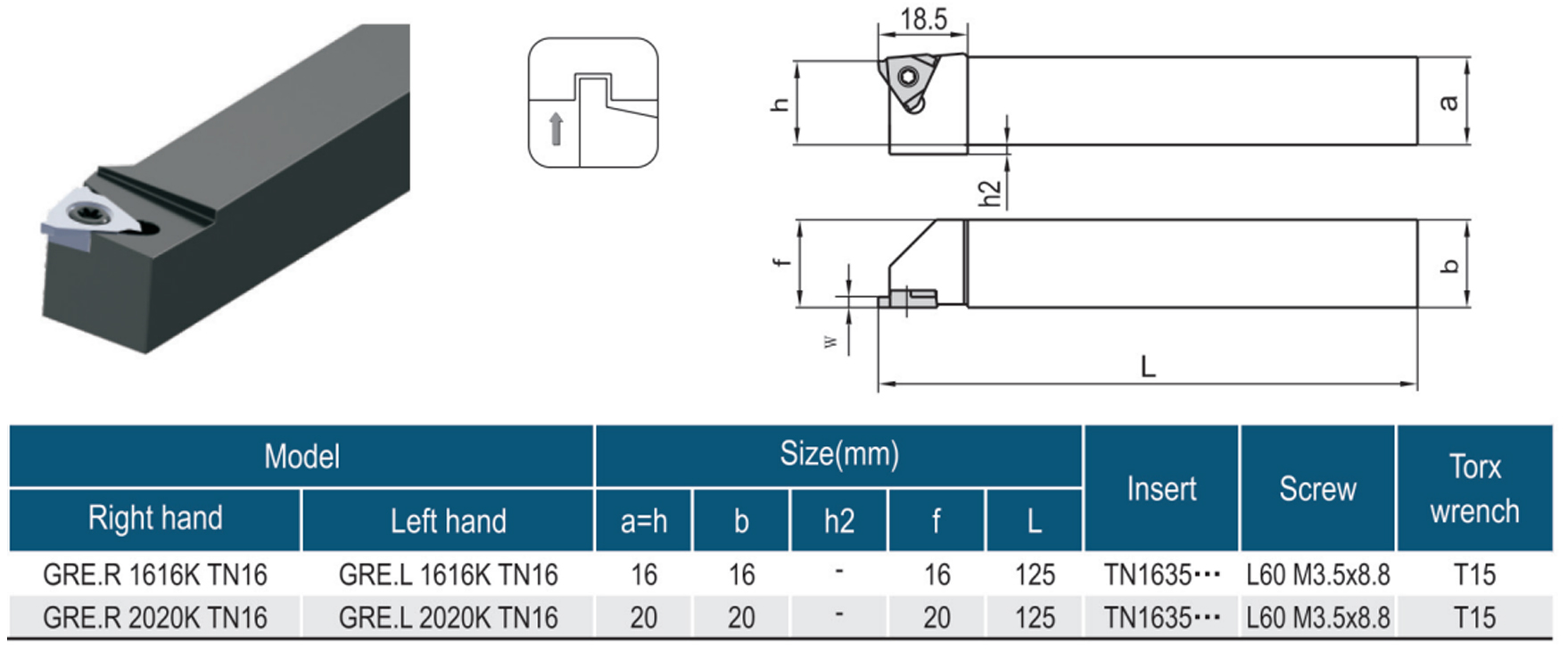

The GRE external grooving toolholder is primarily used for external grooving during machining processes. External grooving toolholder enables the precise cutting of uniform grooves on the surface of workpieces, which are often used for fitting sealing rings, retaining rings, or connecting components, requiring exact dimensions and a high surface finish. The design generally consists of a tool body and interchangeable inserts, allowing for adjustments to accommodate different groove widths and depths, making it versatile across various workpieces and applications.

Usage Method

Select the Appropriate Insert: Choose an insert according to the required groove width and depth. Ensure the insert is securely installed.

Set Machining Parameters: Determine the cutting speed, feed rate, and depth. It is recommended to adjust parameters gradually for optimal cutting performance.

Mounting and Alignment: Install the external grooving toolholder onto a CNC machine or other equipment, aligning the tool and the machining position on the workpiece. Ensure the tool is perpendicular to the workpiece to prevent deviation.

Start Cutting: Feed the tool gradually, ensuring smooth tool operation during cutting. A stepwise, incremental approach is generally used to deepen the groove gradually, avoiding excessive initial depth, which could damage the tool or reduce machining quality.

Usage Precautions

Tool Selection: Ensure that the external grooving toolholder and insert are suitable for the material being machined. Harder materials require more wear-resistant tools to avoid premature tool wear.

Cooling and Lubrication: High heat is generated during external grooving, so cooling fluid or lubricant should be applied to extend tool life and ensure groove wall surface quality.

Control of Cutting Depth: Avoid excessive cutting depth per pass to prevent overloading the tool. Gradual cuts are recommended to reach the final groove depth.

Safety Operations: Turn off power and wear protective gear when changing tools or adjusting equipment to prevent injury from flying debris.

Tool Maintenance: After machining, clean the tool to remove chips to prevent any adverse effects on the tool during the next use.

The GRE external grooving toolholder is widely used in machining, enabling precise groove processing to achieve component assembly and sealing functions. Following the above steps and precautions ensures not only machining quality but also extends tool life.

Contact: Jason Lee

Email: jason@wayleading.com

Post time: Oct-30-2024