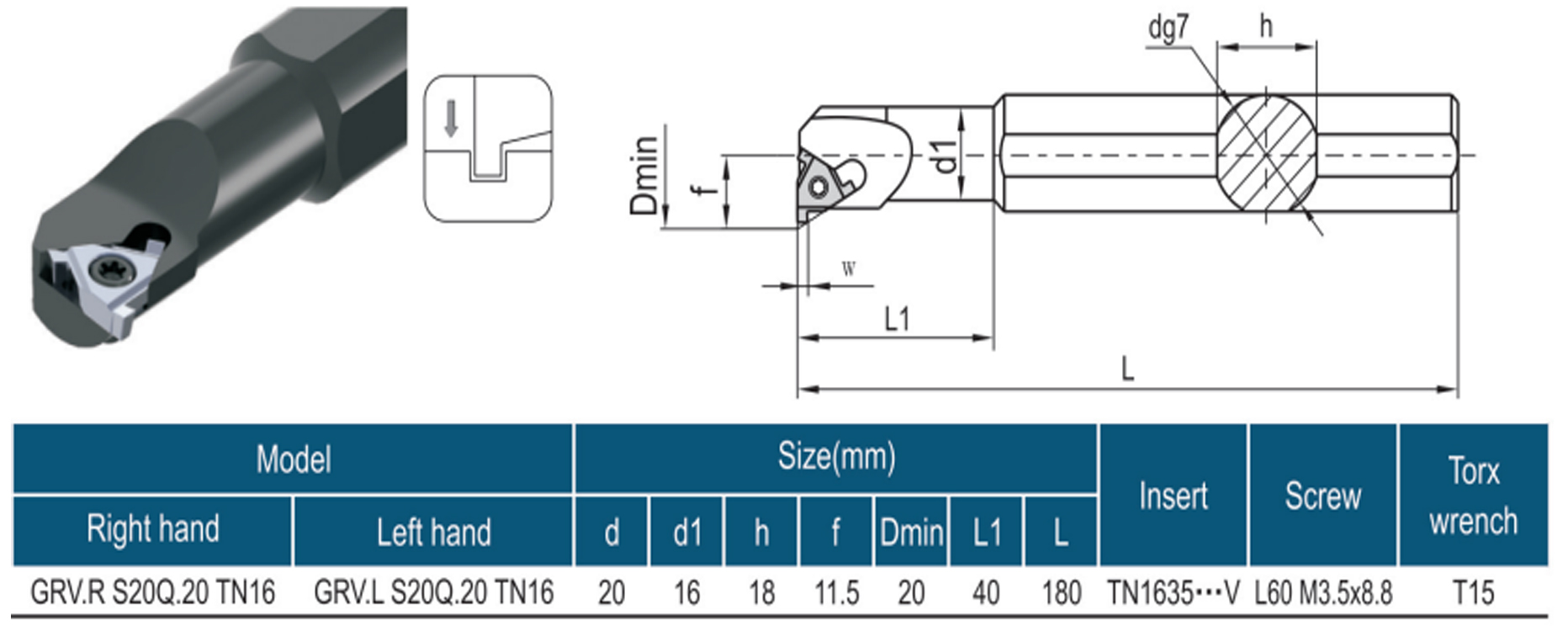

GRV Internal Grooving Toolholders are suitable for mounting TN1635 inserts, designed specifically for high-precision, high-efficiency internal grooving. GRV internal grooving toolholders are made of high-quality steel, offering excellent wear resistance and impact strength, making them ideal for high-intensity machining in various environments. With a compact structure, these toolholders enable stable cutting in tight spaces. The surface treatment increases corrosion resistance and extends the lifespan of GRV internal grooving toolholders, which are widely used in industries such as machinery manufacturing, automotive parts production, and aerospace.

Usage Instructions

Insert Installation: Place the TN1635 insert into the slot on the GRV internal grooving toolholder, ensuring the insert is securely fitted and the clamping screw is tightened. Avoid excessive force during installation to prevent damage to the insert or the GRV internal grooving toolholder.

Set Cutting Parameters: Adjust the cutting speed, feed rate, and depth according to the workpiece material and processing requirements. For first-time use, conduct a test cut with a small depth to confirm the optimal parameters for the GRV internal grooving toolholder.

Machining Operation: After starting the machine, gradually bring the GRV internal grooving toolholder into contact with the workpiece, slowly increasing the depth of cut. Avoid sudden engagement to prevent tool damage. Continuously supply cutting fluid during the operation to lower temperature and friction.

Precautions

Ensure Tool Rigidity: When using the GRV internal grooving toolholder, ensure sufficient tool rigidity to reduce vibrations and maintain machining precision. Reducing overhang length can enhance rigidity and minimize cutting vibrations.

Regular Tool Inspection: Regularly inspect the insert for wear during use and replace it when necessary to maintain optimal performance of the GRV internal grooving toolholder. If there are visible damages or corrosion on the toolholder, it should be replaced immediately.

Proper Cutting Fluid Supply: Ensure sufficient cutting fluid supply when using the GRV internal grooving toolholder to reduce temperature and extend tool life, especially for hard materials.

Follow Operational Guidelines: Avoid excessive cutting speed and feed rates that may overburden the GRV internal grooving toolholder. If there is unusual noise or vibration during machining, stop the machine immediately and check the tool setup.

Cleaning and Storage: After machining, clean the GRV internal grooving toolholder and the insert to remove chips and any residual cutting fluid to prevent corrosion. Store in a dry environment to ensure the GRV internal grooving toolholder’s longevity and stability.

The GRV internal grooving toolholders paired with TN1635 inserts improve machining precision and increase efficiency, making them an ideal solution for high-demand internal grooving applications.

Contact: Jason Lee

Email: jason@wayleading.com

Post time: Oct-30-2024