In the realm of modern machining and manufacturing, precision and reliability are critical. One often underappreciated but vital tool in this context is the Pull Studs Wrench. This specialized tool is used for tightening or loosening pull studs on BT tool holders, playing a crucial role in ensuring that machinery operates efficiently and accurately.

What Are Pull Studs?

Pull studs, also known as pull bolts, are integral components in the toolholding systems of CNC (Computer Numerical Control) machines, particularly those that utilize BT (BT Tool Holder) systems. These pull studs are designed to securely fasten the tool holder to the spindle of the machine. By maintaining a firm connection between the tool holder and spindle, pull studs help to ensure that the tool remains stable and centered during operation. This stability is essential for achieving precise machining results and maintaining the quality of the workpiece.

The Role of a Pull Studs Wrench

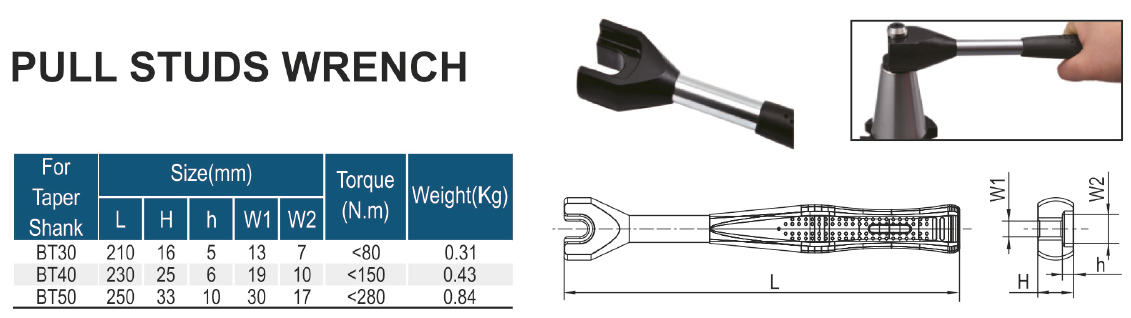

A Pull Studs Wrench is a dedicated tool used to install or remove these pull studs. Its design typically features a robust handle and a head that precisely fits the pull studs, allowing the operator to apply the necessary torque without causing damage. The tool’s primary function is to enable proper tightening or loosening of the pull studs, which is crucial for maintaining the stability and alignment of the tool holder.

Correctly using a Pull Studs Wrench ensures that pull studs are adequately secured. This is vital because if a pull stud is not tightened properly, it can lead to tool holder instability. Such instability can cause tool runout, resulting in inaccurate cuts, reduced machining precision, and potential damage to the workpiece.

Choosing the Right Pull Studs Wrench

Selecting the appropriate Pull Studs Wrench involves considering several key features to ensure it meets the needs of your machinery:

1. Material and Construction: The wrench should be made from high-quality, durable materials like hardened steel or alloy. This ensures that the tool can withstand the forces applied during use without deforming or breaking.

2.Design and Ergonomics: A comfortable grip and ergonomic design are essential, especially for extended periods of use. A well-designed handle reduces operator fatigue and allows for better control during tightening or loosening.

3.Torque Settings: Some advanced Pull Studs Wrenches come with adjustable torque settings or calibration features. These allow for precise application of the required torque, which can enhance the accuracy and efficiency of tool changes.

Usage Tips

To maximize the effectiveness of a Pull Studs Wrench, follow these usage tips:

1.Alignment: Ensure that the wrench is correctly aligned with the pull stud before applying torque. Misalignment can lead to uneven force distribution, potentially causing damage to the pull stud or the tool holder.

2.Apply Adequate Torque: Refer to the manufacturer’s specifications for the appropriate torque settings. Applying too much or too little torque can result in improper fastening, leading to tool instability.

3.Regular Maintenance: Regularly inspect both the pull studs and the wrench for wear and tear. Keeping these components in good condition helps maintain optimal performance and extends their lifespan.

Conclusion

In summary, the Pull Studs Wrench, while a specialized tool, is essential for the proper maintenance and operation of BT tool holders. By ensuring that pull studs are securely fastened, this tool contributes significantly to the stability and accuracy of CNC machines. Investing in a high-quality Pull Studs Wrench and using it correctly can enhance machining precision, reduce downtime, and improve overall manufacturing efficiency. Its role in maintaining equipment integrity underscores its importance in modern machining practices.

Contact: sales@wayleading.com

Post time: Aug-06-2024