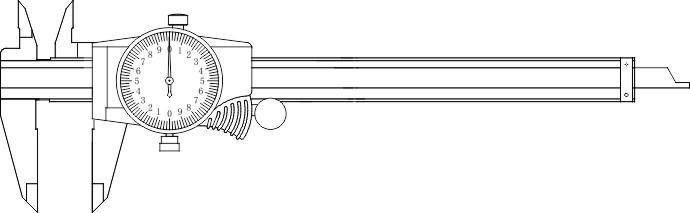

Precision Dial Caliper Of Double Shock-Proof For Industrial

Dial Caliper

We are pleased that you are interested in our Double Shock-Proof Dial Caliper. It is a precision measuring tool widely used in manufacturing, machining, metalworking, and other fields.

Metric

| Range | Graduation | Order Number |

| 0-100mm | 0.02mm | 860-0697 |

| 0-150mm | 0.02mm | 860-0698 |

| 0-200mm | 0.02mm | 860-0699 |

| 0-300mm | 0.02mm | 860-0700 |

| 0-100mm | 0.01mm | 860-0701 |

| 0-150mm | 0.01mm | 860-0702 |

| 0-200mm | 0.01mm | 860-0703 |

| 0-300mm | 0.01mm | 860-0704 |

Inch

| Range | Graduation | Order Number |

| 0-4" | 0.001" | 860-0705 |

| 0-6" | 0.001" | 860-0706 |

| 0-8" | 0.001" | 860-0707 |

| 0-12" | 0.001" | 860-0708 |

Metric & Inch

| Range | Graduation | Order Number |

| 0-100mm/4" | 0.02mm/0.001" | 860-0709 |

| 0-150mm/6" | 0.02mm/0.001" | 860-0710 |

| 0-200mm/8" | 0.02mm/0.001" | 860-0711 |

| 0-300mm/12" | 0.02mm/0.001" | 860-0712 |

Application

Functions For Dial Caliper:

1. Measuring External Diameter: Using the external jaws to measure the outer dimensions of an object.

2. Measuring Internal Diameter: Using the internal jaws to measure the inner dimensions of an object.

3. Measuring Depth: Using the depth rod to measure the depth of holes or recesses.

4. Measuring Step Height: Using the bottom of the caliper to measure the height difference between surfaces.

Usage For Dial Caliper:

1. Clean the Caliper: Ensure the measuring surfaces of the caliper and the object are clean and free of dust before use to guarantee accuracy.

2. Zero Calibration: Fully close the caliper and ensure the dial points to zero. If not, adjust the zero set screw.

3. Measuring External Diameter:

*Open the external jaws and place them around the object.

*Slowly close the jaws until they lightly touch the object's surface.

*Read the measurement from the dial.

4. Measuring Internal Diameter:

*Insert the internal jaws into the hole of the object.

*Open the internal jaws until they lightly touch the inner walls.

*Read the measurement from the dial.

5. Measuring Depth:

*Insert the depth rod into the hole or recess of the object.

*Ensure the depth rod is perpendicular to the surface.

*Read the measurement from the dial.

6. Measuring Step Height:

*Position the base of the caliper on one surface and extend the jaw to the step.

*Adjust the jaws to measure the height difference.

*Read the measurement from the dial.

Precautions For Dial Caliper:

1. Avoid Impacts: Avoid subjecting the caliper to heavy impacts, as even shock-proof designs have limits.

2. Apply Gentle Pressure: Do not apply excessive force during measurements to prevent damage and ensure accuracy.

3. Environmental Temperature: Use in a room-temperature environment to avoid the influence of extreme temperatures on measurements.

4. Regular Calibration: Regularly calibrate the caliper to maintain measurement accuracy.

5. Prevent Rust: Clean the caliper after use and apply a thin layer of anti-rust oil on the surface.

6. Proper Storage: When not in use, store the caliper in a dry toolbox to avoid humid conditions.

Advantage

Efficient and Reliable Service

Wayleading Tools, your one-stop supplier for cutting tools, machinery accessories, measuring tools. As an integrated industrial powerhouse, we take immense pride in our Efficient and Reliable Service, tailored to meet the diverse needs of our esteemed clientele. Click Here For More

Good Quality

At Wayleading Tools, our commitment to Good Quality sets us apart as a formidable force in the industry. As an integrated powerhouse, we offer a diverse range of cutting-edge industrial solutions, providing you with the finest cutting tools, precise measuring instruments, and reliable machine tool accessories.Click Here For More

Competitive Pricing

Welcome to Wayleading Tools, your one-stop supplier for cutting tools, measuring tools, machinery accessories. We take immense pride in offering Competitive Pricing as one of our core advantages. Click Here For More

OEM, ODM, OBM

At Wayleading Tools, we take pride in offering comprehensive OEM (Original Equipment Manufacturer), ODM (Original Design Manufacturer), and OBM (Own Brand Manufacturer) services, catering to your unique needs and ideas.Click Here For More

Extensive Variety

Welcome to Wayleading Tools, your all-in-one destination for cutting-edge industrial solutions, where we specialize in cutting tools, measuring instruments, and machine tool accessories. Our core advantage lies in offering an Extensive Variety of products, tailored to meet the diverse needs of our esteemed clientele.Click Here For More

Matching Items

Matched Caliper:Vernier Caliper, Digital Caliper

Solution

Technical Support:

We are delighted to be your solution provider for dial caliper. We are happy to offer you technical support. Whether it's during your sales process or your customers' usage, upon receiving your technical inquiries, we will promptly address your questions. We promise to reply within 24 hours at the latest, providing you with technical solutions.Click Here For More

Customized Services:

We are pleased to offer you customized services for dial caliper. We can provide OEM services, manufacturing products according to your drawings; OBM services, branding our products with your logo; and ODM services, adapting our products according to your design requirements. Whatever customized service you require, we promise to provide you with professional customization solutions.Click Here For More

Training Services:

Whether you are the purchaser of our products or an end-user, we are more than happy to provide training service to ensure you use the products you purchased from us correctly. Our training materials come in electronic documents, videos, and online meetings, allowing you to choose the most convenient option. From your request for training to our provision of training solutions, we promise to complete the entire process within 3 days Click Here For More

After-sales Service:

Our products come with a 6-month after-sales service period. During this period, any problems not intentionally caused will be replaced or repaired free of charge. We provide round-the-clock customer service support, handling any usage queries or complaints, ensuring you have a pleasant purchasing experience. Click Here For More

Solution Design:

By providing your machining product blueprints (or assisting in creating 3D drawings if unavailable), material specifications, and mechanical details used, our product team will tailor the most suitable recommendations for cutting tools, mechanical accessories, and measuring instruments, and design comprehensive machining solutions for you. Click Here For More

Packing

Packaged in a plastic box. Then packed in an outer box. It can be well protect the dial caliper. Also customized packing is welcomed.

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.