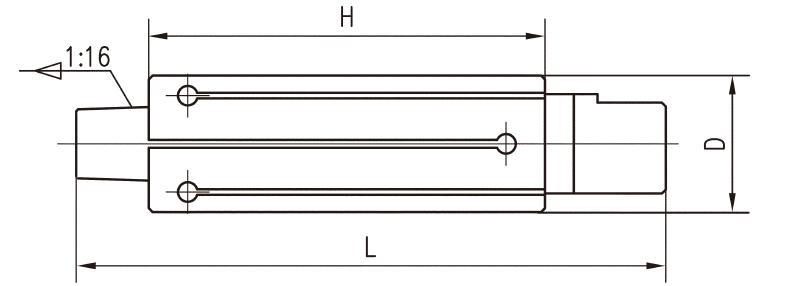

Precision Expanding Mandrel From 9/16" to 3-3/4"

Expanding Mandrel

● Hardened & precision ground for maximum concentricity and holding power.

● Center holes are ground and lapped.

● Automatic expansion feature can be used on any bore within the range of the mandrel standard or non-standard.

● Size up to 1″ are furnished with 1 sleeve larger sizes have 2 sleeve, 1 large and 1 small.

| D(in) | L(in) | H(in) | Sleeves | Order No. |

| 1/2"-9/16" | 5 | 2-1/2 | 1 | 660-8666 |

| 9/16"-21/32" | 6 | 2-3/4 | 1 | 660-8667 |

| 21/31"-3/4" | 7 | 2-3/4 | 1 | 660-8668 |

| 3/4"-7/8" | 7 | 3-1/4 | 1 | 660-8669 |

| 7/8"-1" | 7 | 3-1/2 | 1 | 660-8670 |

| 1"-(1-1/4") | 9 | 4 | 2 | 660-8671 |

| (1-1/4")-(1-1/2") | 9 | 4 | 2 | 660-8672 |

| (1-1/2")-2“ | 11.5 | 5 | 2 | 660-8673 |

| 2”-(2-3/4") | 14 | 6 | 2 | 660-8674 |

| (2-3/4”)-(3-3/4") | 17 | 7 | 2 | 660-8675 |

Secure Workpiece Holding

The Expanding Mandrel is a versatile tool with a wide range of applications in the precision engineering and manufacturing industries. Its primary function is to provide a secure and accurate means of holding a workpiece during machining operations.

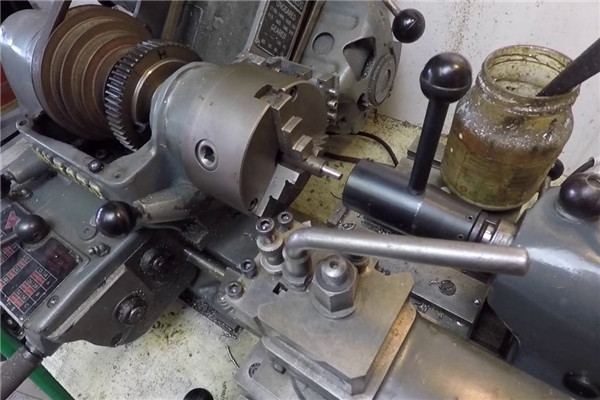

Precision Turning

One of the key applications of the Expanding Mandrel is in the turning process on lathes. Its ability to expand and contract allows it to accommodate various diameters of workpieces, making it ideal for precision turning of components such as gears, pulleys, and bushings. This adaptability is particularly valuable in custom or small-batch production, where the variety of workpiece sizes can be significant.

Grinding Operations

In grinding operations, the Expanding Mandrel excels due to its ability to maintain concentricity and precision. It is particularly useful in the grinding of cylindrical parts, where uniformity and surface finish are critical. The mandrel’s design ensures that the workpiece is held firmly but without excess pressure, reducing the risk of deformation.

Milling Applications

The tool is also widely used in milling applications. It allows for the secure clamping of workpieces that are irregularly shaped or difficult to hold with traditional methods. The uniform clamping pressure of the Expanding Mandrel minimizes the chances of the workpiece shifting during the milling process, thus ensuring accuracy and consistency.

Inspection and Quality Control

Additionally, the Expanding Mandrel finds applications in inspection and quality control processes. Its precise holding capability makes it an excellent choice for holding components during detailed inspection, especially in high-precision industries like aerospace and medical device manufacturing.

The Expanding Mandrel is an invaluable tool in various machining processes, including turning, grinding, milling, and inspection. Its ability to adapt to different sizes and shapes of workpieces, combined with its precision gripping, makes it a key component in achieving high-quality machining results.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Expanding Mandrel

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.