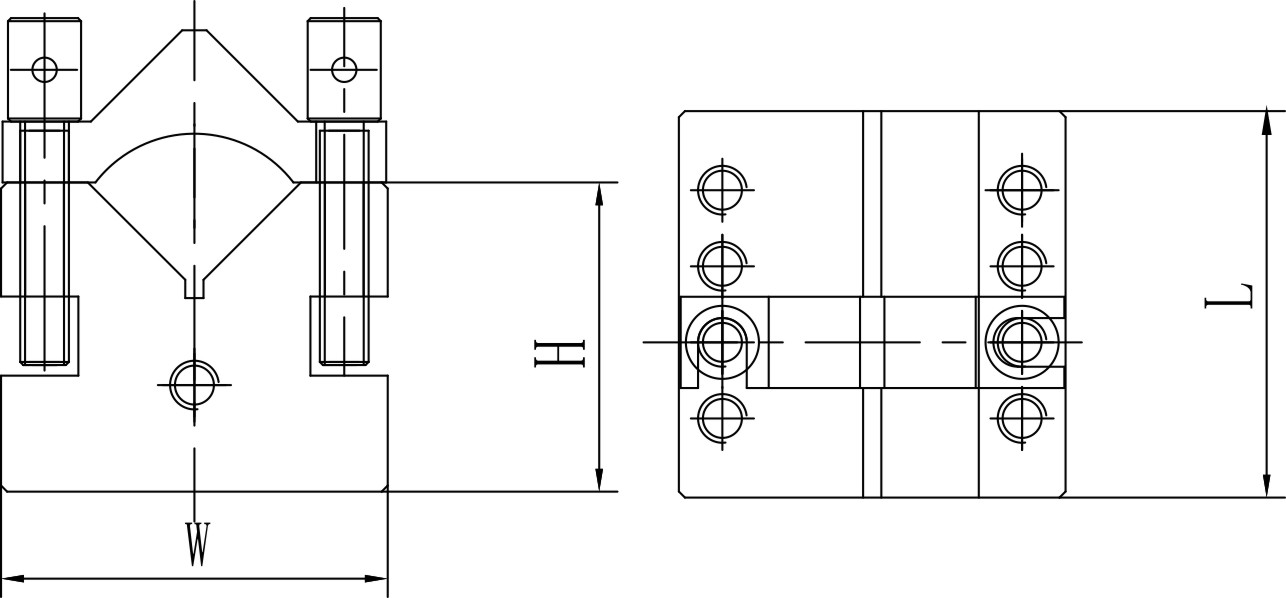

Precision V Block And Clamps Set With High Quality Type

V Block And Clamps Set

● Hardness HRC: 52-58

● Accuracy: 0.0003"

● Square: 0.0002"

| Size(LxWxH) | Clamping Range(mm) | Order No. |

| 1-3/8"x1-3/8"x1-3/16" | 3-15 | 860-0982 |

| 2-3/8"x2-3/8"x2" | 8-30 | 860-0983 |

| 4-1/8"x4-1/8"x3-1/16" | 6-65 | 860-0984 |

| 3"x4"x3" | 6-65 | 860-0985 |

| 35x35x30mm | 3-15 | 860-0986 |

| 60x60x50mm | 4-30 | 860-0987 |

| 100x75x75mm | 6-65 | 860-0988 |

| 105x105x78mm | 6-65 | 860-0989 |

V Blocks and Clamps in Precision Workholding

V blocks and clamps are fundamental tools in the realm of precision workholding, playing a crucial role in securing and positioning workpieces with unparalleled accuracy. This dynamic duo finds extensive applications across various industries where precision machining, inspection, and assembly are paramount.

Machining Excellence

In machining operations, V blocks and clamps are indispensable for holding and securing components during milling, drilling, and grinding processes. The V-shaped groove in the block allows for the stable positioning of cylindrical or round workpieces, ensuring that machining operations are carried out with precision and repeatability.

Inspection and Metrology

The accuracy provided by V blocks makes them invaluable in inspection and metrology applications. Machined components can be securely placed in V blocks for thorough inspection using measuring instruments. This setup enables inspectors to verify dimensions, angles, and concentricity with high precision, ensuring adherence to tight tolerances.

Tool and Die Making

In the field of tool and die making, where precision is non-negotiable, V blocks and clamps are essential. These tools facilitate the precise positioning of workpieces during the creation and verification of intricate molds and dies. The stability offered by V blocks ensures that the machining processes result in components with the exact specifications required for tool and die production.

Welding and Fabrication

V blocks and clamps play a critical role in welding and fabrication processes. Welders use V blocks to securely hold and align metal pieces, ensuring that welds are executed with accuracy. The clamps provide the necessary pressure to hold the components firmly in place, contributing to the structural integrity of the welded assembly.

Assembly Operations

During assembly processes, V blocks and clamps aid in the precise alignment and fitting of components. Whether in automotive manufacturing or aerospace assembly, these tools ensure that parts are securely held in the correct orientation for assembly. The result is a final product that meets strict quality standards and functional requirements.

Educational Training

V blocks and clamps are valuable tools in educational settings, especially in engineering and machining courses. Students use these tools to learn about workholding principles, geometric tolerances, and precision measurement. The hands-on experience gained through working with V blocks and clamps enhances students’ understanding of fundamental concepts in engineering.

Rapid Prototyping

In the realm of rapid prototyping, where quick and accurate validation of designs is crucial, V blocks and clamps find application. These tools aid in securing prototype components during testing and evaluation, ensuring that the design specifications are met before moving to full-scale production.

Aerospace and Defense

In the aerospace and defense industries, where components must meet stringent quality and safety standards, V blocks and clamps are integral. These tools contribute to the precision manufacturing of critical parts, such as aircraft components and defense equipment, ensuring that every piece aligns with exact specifications. The applications of V blocks and clamps are diverse and vital across industries that prioritize precision and accuracy. From machining to inspection, tool and die making to assembly operations, these tools stand as essential components in the toolkit of precision workholding, contributing to the production of high-quality, reliable, and meticulously crafted components.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x V Block

1 x Protective Case

1x Inspection Report By Our Factory

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.