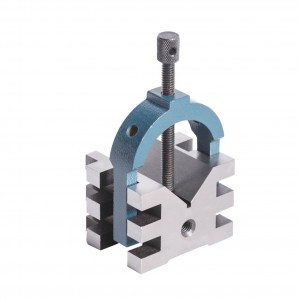

Precision V Block And Clamps Set With High Quality Type

V Block And Clamps Set

● Hardness HRC: 52-58

● Accuracy: 0.0003"

● Square: 0.0002"

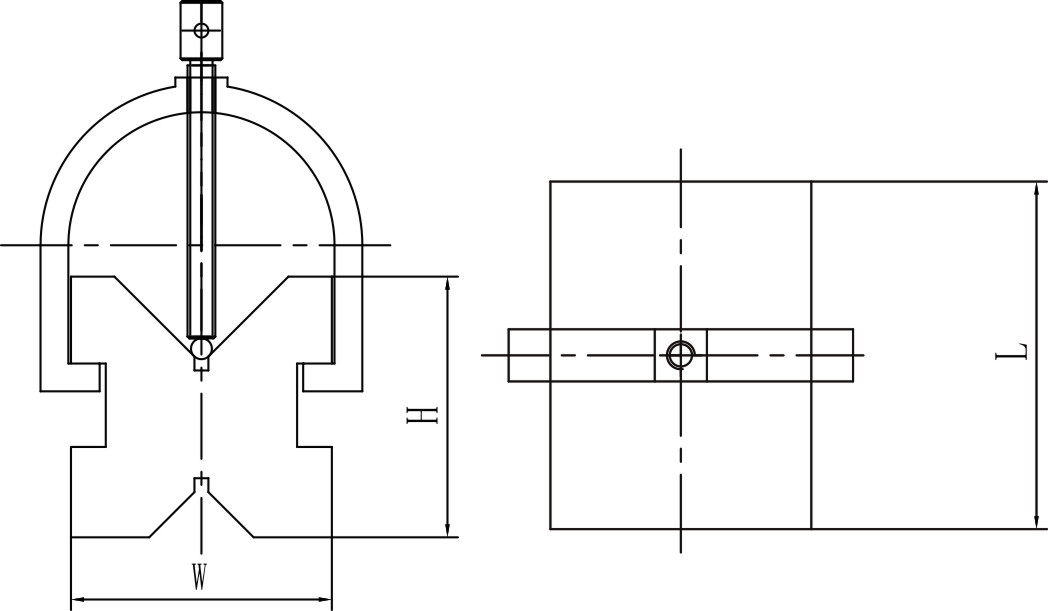

| Size(LxWxH) | Clamping Range(mm) | Order No. |

| 1-5/8"x1-1/4"x1-1/4" | 4-26 | 860-0990 |

| 1-3/4"x1-5/8"x1-3/8" | 6-32 | 860-0991 |

| 2-3/4"x1-3/4"x1-5/8" | 6-30 | 860-0992 |

| 2-3/4"x2-1/4"x1-3/4" | 6-45 | 860-0993 |

| 4-7/8"x3-1/2"x2-3/4" | 6-75 | 860-0994 |

| 45x40x35mm | 5-36 | 860-0995 |

| 41x32x32mm | 5-26 | 860-0996 |

| 70x44x41mm | 6-60 | 860-0997 |

| 70x63x44mm | 6-45 | 860-0998 |

| 125x90x70mm | 8-80 | 860-0999 |

| 50x40x40mm | 6-36 | 860-1000 |

| 75x55x55mm | 6-50 | 860-1001 |

| 100x75x75mm | 8-65 | 860-1002 |

The Role of V Blocks and Clamps

In the intricate world of precision workholding, V blocks and clamps stand as stalwart tools, wielding unmatched capabilities in securing and positioning workpieces with exceptional accuracy. This dynamic pairing finds extensive utility across diverse industries where precision machining, thorough inspection, and meticulous assembly are not just desired but imperative.

Machining Mastery

Within machining operations, V blocks and clamps emerge as indispensable allies, providing steadfast support during milling, drilling, and grinding processes. The V-shaped groove in these blocks ensures a stable hold for cylindrical or round workpieces, allowing machining operations to unfold with a symphony of precision and repeatability.

Inspection Precision and Metrology

The inherent accuracy of V blocks renders them invaluable in inspection and metrology applications. Machined components securely cradled in V blocks undergo meticulous scrutiny using precision measuring instruments. This setup empowers inspectors to scrutinize dimensions, angles, and concentricity with a degree of precision that aligns seamlessly with stringent tolerances.

Tool and Die Making Excellence

In the realm of tool and die making, where precision is the bedrock, V blocks and clamps take center stage. These tools facilitate the precise placement of workpieces during the creation and verification of intricate molds and dies. The stability afforded by V blocks ensures that machining processes yield components with exact specifications crucial for tool and die production.

Welding and Fabrication Precision

V blocks and clamps assume a critical role in welding and fabrication processes. Welders leverage V blocks to securely grip and align metal pieces, orchestrating welds with a symphony of accuracy. Clamps, with their firm pressure, contribute to the structural integrity of the welded assembly, ensuring a seamless integration of components.

Assembly Operations Harmony

During assembly processes, V blocks and clamps serve as conductors orchestrating the precise alignment and fitting of components. Whether in the automotive or aerospace domain, these tools ensure that parts are cradled securely in the correct orientation, laying the foundation for an assembly that meets exacting quality standards and functional requirements.

Educational Empowerment

V blocks and clamps emerge as valuable educational tools, particularly in engineering and machining courses. Students engage with these tools to grasp workholding principles, geometric tolerances, and precision measurement. The hands-on experience gained through these tools enriches students’ comprehension of fundamental engineering concepts.

Rapid Prototyping Assurance

In the fast-paced realm of rapid prototyping, where swift and accurate validation is paramount, V blocks and clamps come to the forefront. These tools contribute to securing prototype components during testing and evaluation, ensuring that design specifications are met before transitioning to full-scale production.

Aerospace and Defense Precision

In the aerospace and defense industries, where adherence to stringent quality and safety standards is non-negotiable, V blocks and clamps become integral. These tools play a pivotal role in the precision manufacturing of critical components, guaranteeing alignment with exact specifications for aircraft components and defense equipment.

The applications of V blocks and clamps are not just diverse but pivotal across industries that prioritize precision and accuracy. From machining to inspection, tool and die making to assembly operations, these tools stand as indispensable elements in the arsenal of precision workholding, contributing to the creation of high-quality, reliable, and meticulously crafted components.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x V Block

1 x Protective Case

1x Inspection Report By Our Factory

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.