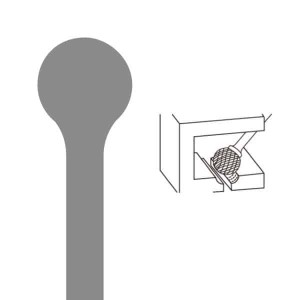

Type D Ball Tungsten Carbide Rotary Burr

Type D Ball Tungsten Carbide Rotary Burr

● Cuts: Single, Double, Diamond, Alu Cuts

● Coating: Could Coate by TiAlN

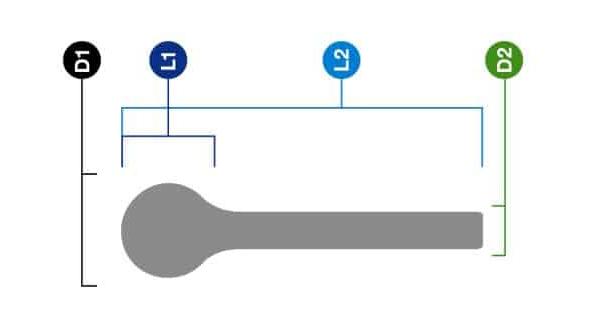

Metric

| Model | D1 | L1 | L2 | D2 | Single Cut | Double Cut | Diamond Cut | Alu Cut |

| D0302 | 3 | 2 | 40 | 3 | 660-2956 | 660-2964 | 660-2972 | 660-2980 |

| D0403 | 4 | 3 | 34 | 3 | 660-2957 | 660-2965 | 660-2973 | 660-2981 |

| D0605 | 6 | 5 | 35 | 3 | 660-2958 | 660-2966 | 660-2974 | 660-2982 |

| D0605 | 6 | 5 | 50 | 6 | 660-2959 | 660-2967 | 660-2975 | 660-2983 |

| D0807 | 8 | 7 | 47 | 6 | 660-2960 | 660-2968 | 660-2976 | 660-2984 |

| D1009 | 10 | 9 | 49 | 6 | 660-2961 | 660-2969 | 660-2977 | 660-2985 |

| D1210 | 12 | 10 | 51 | 6 | 660-2962 | 660-2970 | 660-2978 | 660-2986 |

| D1614 | 16 | 14 | 54 | 6 | 660-2963 | 660-2971 | 660-2979 | 660-2987 |

Inch

| Model | D1 | L1 | D2 | Single Cut | Double Cut | Diamond Cut | Alu Cut |

| SD-42 | 1/8" | 1/8" | 1/8" | 660-3330 | 660-3342 | 660-3354 | 660-3366 |

| SD-41 | 3/32" | 3/32" | 1/8" | 660-3331 | 660-3343 | 660-3355 | 660-3367 |

| SD-11 | 1/8" | 3/32" | 1/4" | 660-3332 | 660-3344 | 660-3356 | 660-3368 |

| SD-14 | 3/16" | 1/8" | 1/4" | 660-3333 | 660-3345 | 660-3357 | 660-3369 |

| SD-1 | 1/4" | 7/32" | 1/4" | 660-3334 | 660-3346 | 660-3358 | 660-3370 |

| SD-2 | 5/16" | 1/4" | 1/4" | 660-3335 | 660-3347 | 660-3359 | 660-3371 |

| SD-3 | 3/8" | 5/16" | 1/4" | 660-3336 | 660-3348 | 660-3360 | 660-3372 |

| SD-4 | 7/16" | 3/8" | 1/4" | 660-3337 | 660-3349 | 660-3361 | 660-3373 |

| SD-5 | 1/2" | 7/16" | 1/4" | 660-3338 | 660-3350 | 660-3362 | 660-3374 |

| SD-6 | 5/8" | 9/16" | 1/4" | 660-3339 | 660-3351 | 660-3363 | 660-3375 |

| SD-7 | 3/4" | 11/16" | 1/4" | 660-3340 | 660-3352 | 660-3364 | 660-3376 |

| SD-9 | 1" | 15/16" | 1/4" | 660-3341 | 660-3353 | 660-3365 | 660-3377 |

Essential for Metal Fabrication

Tungsten Carbide Rotary Burrs stand as indispensable instruments in the field of metalworking, celebrated for their versatility and high performance in numerous tasks. The key applications of these tools are.

Deburring and Welding Treatment: In the domain of metal fabrication, the removal of burrs created during welding or cutting is crucial. The remarkable wear resistance and hardness of Tungsten Carbide Rotary Burrs render them exceptionally effective for such detailed deburring activities.

Proficiency in Shaping and Engraving

Shaping and Engraving: Employed for the intricate shaping, engraving, and trimming of metal parts, these rotary burrs demonstrate proficiency in working with a wide array of metals, encompassing both hard alloys and aluminum alloys.

Critical for Grinding and Polishing

Grinding and Polishing: Tungsten Carbide Rotary Burrs are vital in precision metalworking, particularly for grinding and polishing tasks. Their outstanding hardness and durability contribute significantly to their efficacy in these processes.

Preferred for Reaming and Edging

Reaming and Edging: These tools are often the preferred choice for altering or refining the size and shape of existing holes during mechanical fabrication processes.

Key in Cleaning Castings

Cleaning Castings: Within the casting field, Tungsten Carbide Rotary Burrs play a key role in removing extra material from castings and in improving the quality of their surfaces.

Owing to their high efficiency and flexibility, Tungsten Carbide Rotary Burrs are extensively utilized in diverse industries such as manufacturing, automotive repair, metal crafts, and aerospace.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Type C Cylinder Ball Nose Cylinder Tungsten Carbide Rotary Burr

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.