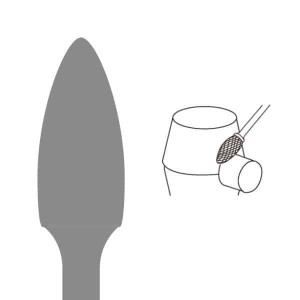

Type H Flame Tungsten Carbide Rotary Burr

Type H Flame Tungsten Carbide Rotary Burr

● Cuts: Single, Double, Diamond, Alu Cuts

● Coating: Could Coate by TiAlN

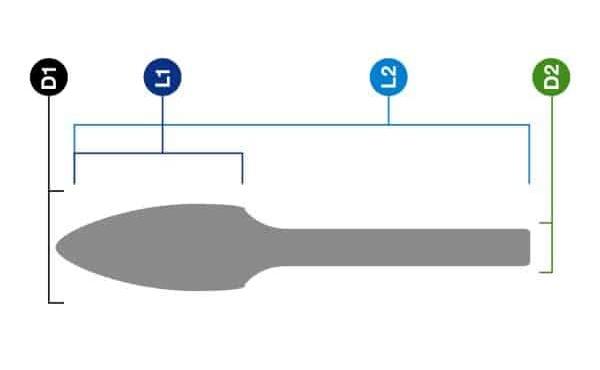

Metric

| Model | D1 | L1 | L2 | D2 | Single Cut | Double Cut | Diamond Cut | Alu Cut |

| H0307 | 3 | 7 | 40 | 3 | 660-3079 | 660-3083 | 660-3087 | 660-3091 |

| H0613 | 6 | 13 | 43 | 3 | 660-3080 | 660-3084 | 660-3088 | 660-3092 |

| H0820 | 8 | 20 | 60 | 6 | 660-3081 | 660-3085 | 660-3089 | 660-3093 |

| H0230 | 12 | 30 | 70 | 6 | 660-3082 | 660-3086 | 660-3090 | 660-3094 |

Inch

| Model | D1 | L1 | D2 | Single Cut | Double Cut | Diamond Cut | Alu Cut |

| SH-41 | 1/8" | 1/4" | 1/8" | 660-3498 | 660-3506 | 660-3514 | 660-3522 |

| SH-53 | 3/16" | 3/8" | 1/4" | 660-3499 | 660-3507 | 660-3515 | 660-3523 |

| SH-1 | 1/4" | 5/8" | 1/4" | 660-3500 | 660-3508 | 660-3516 | 660-3524 |

| SH-2 | 5/16" | 3/4" | 1/4" | 660-3501 | 660-3509 | 660-3517 | 660-3525 |

| SH-3 | 3/8" | 1" | 1/4" | 660-3502 | 660-3510 | 660-3518 | 660-3526 |

| SH-5 | 1/2" | 1-1/4" | 1/4" | 660-3503 | 660-3511 | 660-3519 | 660-3527 |

| SH-6 | 5/8" | 1-7/16" | 1/4" | 660-3504 | 660-3512 | 660-3520 | 660-3528 |

| SH-7 | 3/4" | 1-5/8" | 1/4" | 660-3505 | 660-3513 | 660-3521 | 660-3529 |

Metal Fabrication Deburring

Tungsten Carbide Rotary Burrs enjoy widespread acclaim in the metalworking industry, owing to their diverse applications and outstanding performance across various tasks. Their primary roles encompass.

Deburring and Welding Treatment: Indispensable in metal fabrication, these burrs excel at eliminating burrs generated during welding or cutting processes. Their superior hardness and wear resistance make them well-suited for meticulous deburring

Precise Metal Shaping and Engraving operations

Shaping and Engraving: Renowned for their precision in shaping, engraving, and trimming metal components, Tungsten Carbide Rotary Burrs demonstrate exceptional proficiency with a range of metals, including hard alloys and aluminum alloys.

Enhanced Grinding and Polishing

Grinding and Polishing: Crucial in the realm of precision metalworking, these burrs are particularly effective for grinding and polishing tasks. Their remarkable hardness and durability significantly enhance their performance in these applications.

Mechanical Manufacturing Reaming

Reaming and Edging: Widely utilized for modifying or refining the size and shape of existing holes in mechanical manufacturing processes, Tungsten Carbide Rotary Burrs play a pivotal role.

Casting Surface Cleaning

Cleaning Castings: In the casting industry, these burrs are instrumental in the removal of excess material from castings, contributing to an improved surface finish.

The widespread use of Tungsten Carbide Rotary Burrs in various industries such as manufacturing, automotive repair, metal crafting, and aerospace is a testament to their high efficiency and adaptability.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Type H Flame Tungsten Carbide Rotary Burr

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.